Electric insulated ladder

An insulating ladder and electric power technology, which is applied in the field of electric insulating ladders, can solve the problems of high requirements for joint folders, single function of insulating ladders, high manufacturing cost, etc., and achieves the effects of low manufacturing cost, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

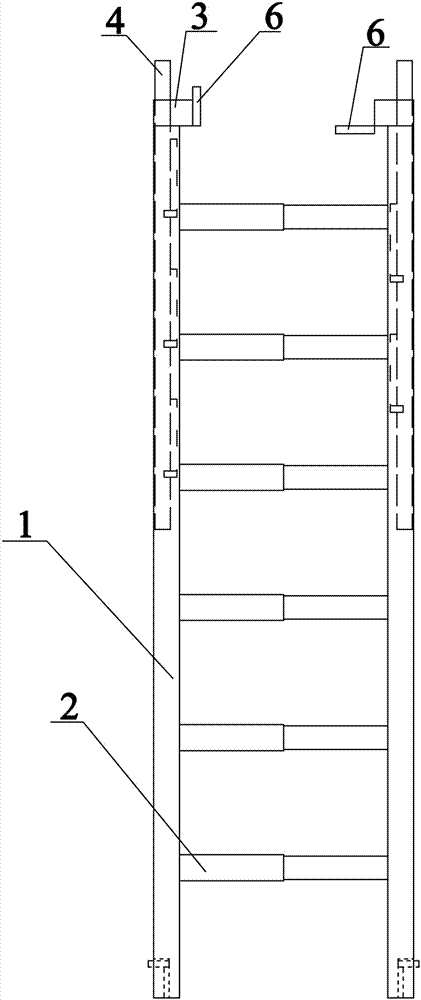

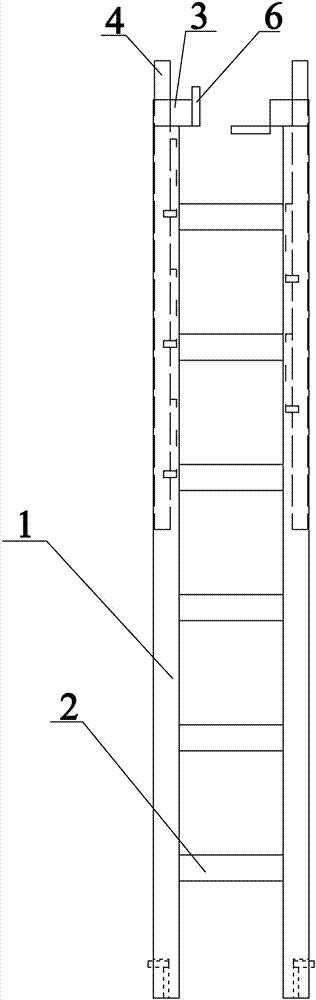

[0031] See Figure 1-5 , A power insulated ladder, comprising a ladder body, the ladder body comprising two vertical rods 1 and a cross rod 2 connected between the two vertical rods 1, the top ends of the two vertical rods 1 are hinged to the connecting block 3, The outer edge of the vertical rod 1 is provided with a horizontal rotating shaft, and the connecting block 3 can be folded upward 90° around the horizontal rotating shaft. The two vertical rods 1 and the connecting block 3 respectively penetrate through the pullable support rod 4, and the support rod 4 The lower end is provided with a limit block, and the position is fixed when the support rod 4 is pulled to the uppermost end of the vertical rod 1. The two support rods 4 are crossed with pedals 5 on the inner sides, and the ends of the pedals 5 are close to the center line of the two vertical rods 1 , So that the insulation ladder does not cross when it is folded (see image 3 with Figure 4 ), the pedal 5 includes a p...

Embodiment 2

[0036] See Image 6 The structure of the power insulation ladder of this embodiment is basically the same as that of the power insulation ladder of embodiment 1, and the similarities will not be repeated. Some differences are: the edge of the pedal 5 is provided with anti-skid protrusions 10, and the support rod 4 is provided with The non-slip protrusion 10 is matched with a depression.

[0037] The surfaces of the vertical rods, cross rods, connecting blocks, support rods, and pedals are all coated with insulating paint, and the insulating paint is made of the following parts by weight: 100 parts of phenyltrichlorosilane and 33 parts of epoxy resin , 105 parts of organic solvent, 35 parts of polyamide resin, 2 parts of curing agent, 12 parts of film forming agent, 0.6 parts of leveling agent, 1.5 parts of dispersant, 6.5 parts of epoxy soybean oil and 9 parts of mica powder.

[0038] The organic solvent is ethyl acetate, the curing agent is benzoyl peroxide, the film-forming agent...

Embodiment 3

[0040] The structure of the power insulation ladder of this embodiment is basically the same as that of the embodiment 2, and the similarities are not repeated. Some differences are: the vertical bars, cross bars, connecting blocks, support bars, and pedals are all coated with insulation. Paint, the insulating paint is made of the following raw materials in parts by weight: 100 parts by weight of phenyltrichlorosilane, 35 parts of epoxy resin, 110 parts of organic solvent, 36 parts of polyamide resin, 2.5 parts of curing agent, 14 parts of film forming agent Parts, 0.8 parts of leveling agent, 1.6 parts of dispersant, 7 parts of epoxy soybean oil and 10 parts of mica powder.

[0041] The organic solvent is toluene, the curing agent is tert-butyl peroxybenzoate, the film forming agent is acrylic resin, the leveling agent is polydimethylsiloxane, and the dispersant is vinyl. Bistearylamide, the particle size of the mica powder is 1000 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com