Antique building reinforced waterproof roof and construction method thereof

A technology of antique buildings and construction methods, applied in the direction of building roofs, roofs, buildings, etc., can solve the problems of roof leakage, erosion, weak waterproof system ability, etc., to strengthen waterproof ability, enhance durability and stability, roof waterproof safety factor boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

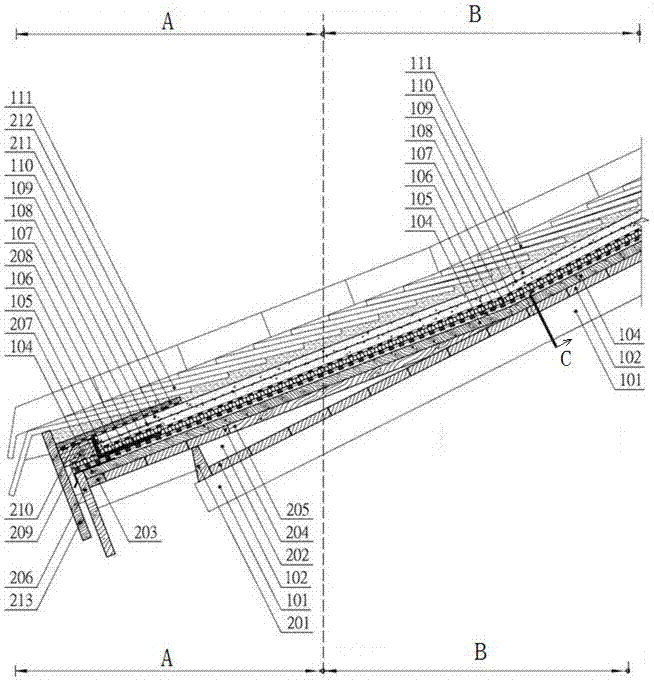

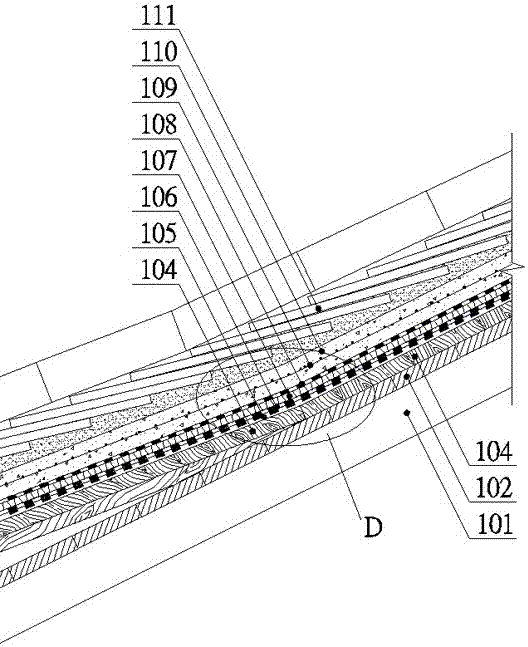

[0051] like Figures 1 to 7 As shown, the reinforced waterproof roof of antique building in this embodiment includes roof area 1 ( figure 1 The area between A-A) and cornice head area 2 ( figure 1 in the region between B-B),

[0052] The roof area 1 includes wooden rafters 101, watch brick layer 102, wooden keel 103, anti-corrosion wood base layer 104, first waterproof coiled material layer 105, second waterproof coiled material layer 106, convex plastic drainage board from the inside to the outside Layer 107, non-woven fabric layer 108, steel mesh layer 109, cement mortar thatch back layer 110, roof tile layer 111;

[0053] The eaves head area 2 includes wooden rafters 101, inner wood 201, watch brick layer 102, wooden flying rafters 202, edge wood 203, second watch brick layer 204, and wooden roof panel layer 205 on the upper part of flying rafters from inside to outside. , Anticorrosion wood base layer 104, wooden fascia board 206, stainless steel drip board 207, first w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com