Flattening antirust oil for cold-rolled steel plates and preparation method thereof

A cold-rolled steel plate and anti-rust oil technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of long production cycle, poor shape of steel plate, high pressure of smooth rolling, etc., and achieve good lubrication and anti-rust performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method for the leveling antirust oil of cold-rolled steel plate as above, comprises the following steps:

[0024] Step (1): Add antioxidant to trimethylolpropane oleate, heat and stir at 60-70°C to dissolve, then add paraffin base oil, multi-effect rust inhibitor, vulcanized olefin cottonseed oil, polyisobutylene Mix and stir for 30-45min to obtain a mixed solution;

[0025] Step (2): Cool down the mixed solution to 45-50°C, add fatty alcohol polyoxyethylene ether-9, mix and stir for 30-45 minutes to obtain smooth antirust oil.

Embodiment 1

[0026] Embodiment 1: leveling antirust oil for cold-rolled steel plate

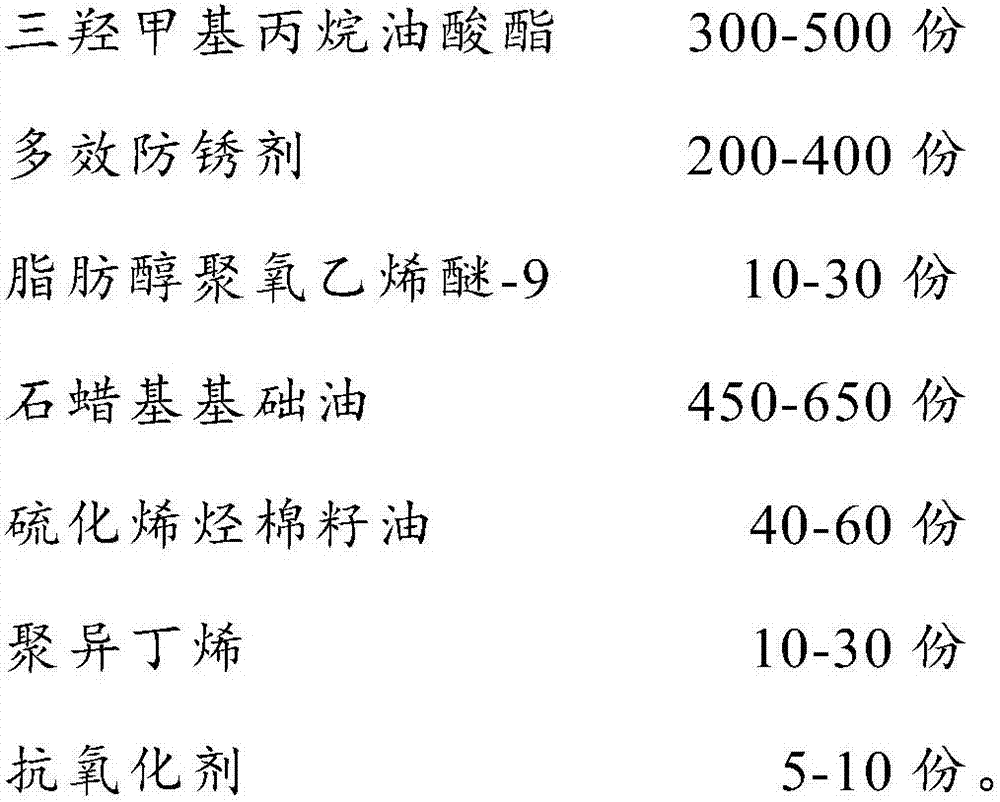

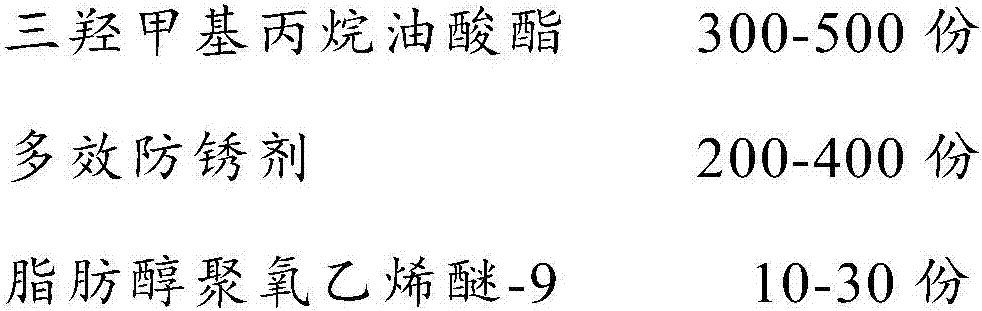

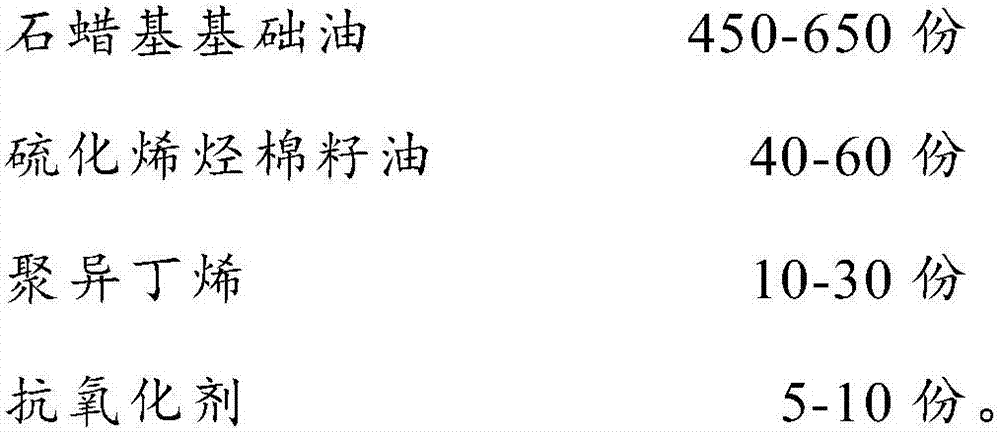

[0027] The raw material of this embodiment consists of:

[0028]

[0029] Wherein, the paraffinic base oil is a 150SN paraffinic base oil with a high viscosity index HVI≥100.

[0030] The preparation method of the leveling antirust oil is as follows: adding an antioxidant to the modified synthetic ester, heating and stirring at 60-70°C to dissolve, then adding paraffin base oil, multi-effect antirust agent, extreme pressure lubricant, bright Mix and stir the agent for 30-45 minutes to obtain a mixed solution; cool the mixed solution to 45-50°C, add fatty alcohol polyoxyethylene ether-9, and mix and stir for 30-45 minutes to obtain smooth antirust oil.

Embodiment 2

[0031] Embodiment 2: leveling antirust oil for cold-rolled steel plate

[0032] The raw material of this embodiment consists of:

[0033]

[0034]

[0035] Wherein, the paraffinic base oil is a 150SN paraffinic base oil with a high viscosity index HVI≥100.

[0036] The preparation method of this flat antirust oil is: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com