Intelligently controlled coal coking smoke waste heat recovery system

A flue gas waste heat and recovery system technology, which is applied in the heating, preheating and coking ovens of coke ovens, can solve the problems of insufficient heat energy recovery and low heat recovery efficiency, and achieve the effect of improving waste heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

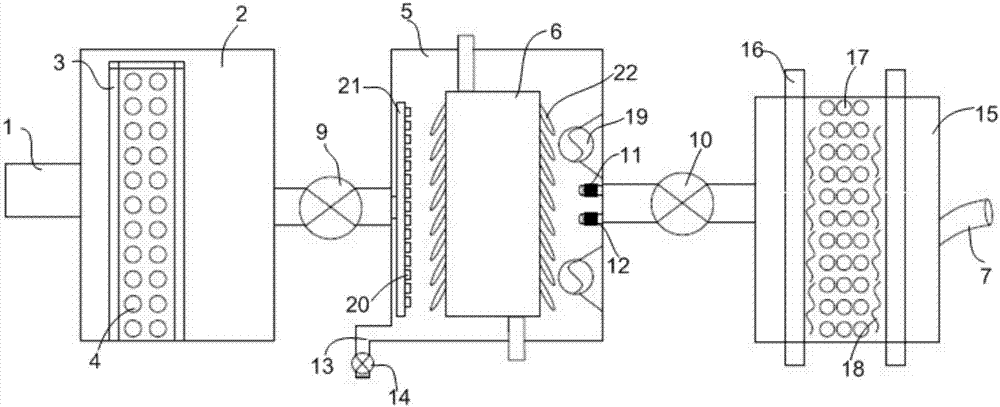

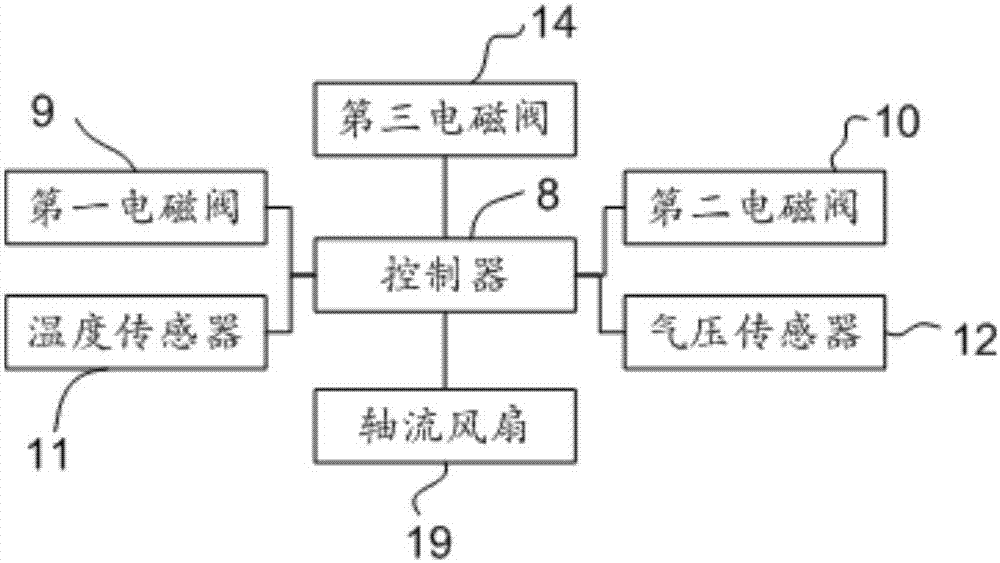

[0018] see figure 1 , the present invention provides an intelligent control briquette coking flue gas waste heat recovery system, which includes an air induction pipe 1 for connecting the introduction of coal coking flue gas. One end of the air-inducing pipe 1 is detachably installed with a buffer frame 3, and a plurality of ceramic buffer balls 4 are placed on the buffer frame 3. The outlet end of the buffer chamber 2 is connected to a heat recovery chamber 5, and an economizer 6 is installed in the heat recovery chamber 5. The water inlet end of the economizer 6 passes through the heat recovery chamber 5 and is placed outside the heat recovery chamber 5, and the water outlet end of the economizer 6 passes through the heat recovery chamber 5 and is placed outside the heat recovery chamber 5 on the top of the heat recovery chamber 5. The outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com