Multicomponent biological compound oil displacement agent system and injection technology thereof

A composite oil displacement agent and biopolymer technology, which is applied in the direction of production fluid, drilling composition, wellbore/well parts, etc., can solve the problems of large amount of surfactant, difficult degradation of polymer, and difficult sewage treatment , to achieve the effect of increasing swept volume, improving recovery and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

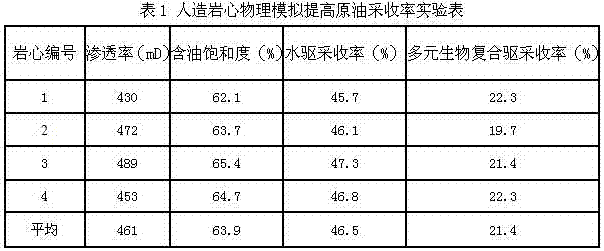

Examples

Embodiment 1

[0038] A multi-component biological composite oil displacement agent system of the present invention is composed of petroleum hydrocarbon degrading bacteria agent and biological composite oil displacement agent,

[0039] The petroleum hydrocarbon-degrading bacterial agent is prepared by uniformly mixing 1 part of petroleum hydrocarbon-degrading bacteria fermentation stock solution and 15 parts of nutrient solution;

[0040]The biocomposite oil displacement agent is composed of the following components by weight ratio: 5 parts of biopolymer bacterial fermentation stock solution, 10 parts of biological lipopeptide surfactant, 1 part of betaine, 60-80 parts of water, pH 8 is controlled, and the system Viscosity 47mpa s;

[0041] The nutrient solution is composed of 0.5 parts of a mixture of corn syrup and sucrose in a mass ratio of 3:1, 0.1 part of diammonium hydrogen phosphate, 0.1 part of sodium nitrate, 0.02 part of potassium humate, and 60 parts of water;

[0042] All the ab...

Embodiment 2

[0064] A multi-component biological composite oil displacement agent system of the present invention is composed of petroleum hydrocarbon degrading bacteria agent and biological composite oil displacement agent,

[0065] The petroleum hydrocarbon-degrading bacterial agent is prepared by uniformly mixing 5 parts of petroleum hydrocarbon-degrading bacteria fermentation stock solution and 20 parts of nutrient solution;

[0066] The biological composite oil displacement agent is composed of the following components by weight ratio: 10 parts of biopolymer bacteria fermentation stock solution, 20 parts of biological lipopeptide surfactant, 5 parts of betaine, 60 to 80 parts of water, pH 9 is controlled, and the system Viscosity 78mpa s;

[0067] The nutrient solution is composed of 5 parts of a mixture of corn syrup and sucrose in a mass ratio of 3:1, 0.5 parts of diammonium hydrogen phosphate, 0.5 parts of sodium nitrate, 0.05 parts of potassium humic acid, and 80 parts of water; ...

Embodiment 3

[0090] A multi-component biological composite oil displacement agent system of the present invention is composed of petroleum hydrocarbon degrading bacteria agent and biological composite oil displacement agent,

[0091] The petroleum hydrocarbon-degrading bacterial agent is prepared by uniformly mixing 3 parts of petroleum hydrocarbon-degrading bacteria fermentation stock solution and 18 parts of nutrient solution;

[0092] The biological composite oil displacement agent is composed of the following components by weight ratio: 8 parts of biopolymer bacteria fermentation stock solution, 15 parts of biological lipopeptide surfactant, 3 parts of betaine, 60-80 parts of water, and the pH is controlled at 8.5 , the system viscosity is 65mpa·s;

[0093] The nutrient solution is composed of 3 parts of a mixture of corn syrup and sucrose in a mass ratio of 3:1, 0.3 parts of diammonium hydrogen phosphate, 0.3 parts of sodium nitrate, 0.05 parts of potassium humic acid, and 70 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| System viscosity | aaaaa | aaaaa |

| System viscosity | aaaaa | aaaaa |

| System viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com