Compound hydrate anti-aggregation agent composition and uses thereof

A technology of hydrate and anti-polymerization agent, which is applied in the direction of drilling composition, gas/liquid distribution and storage, mechanical equipment, etc. It can solve the problems of easy pollution of the environment, poor anti-polymerization performance, large dosage, etc., and achieve good technology Effect, anti-polymerization performance is excellent, the effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

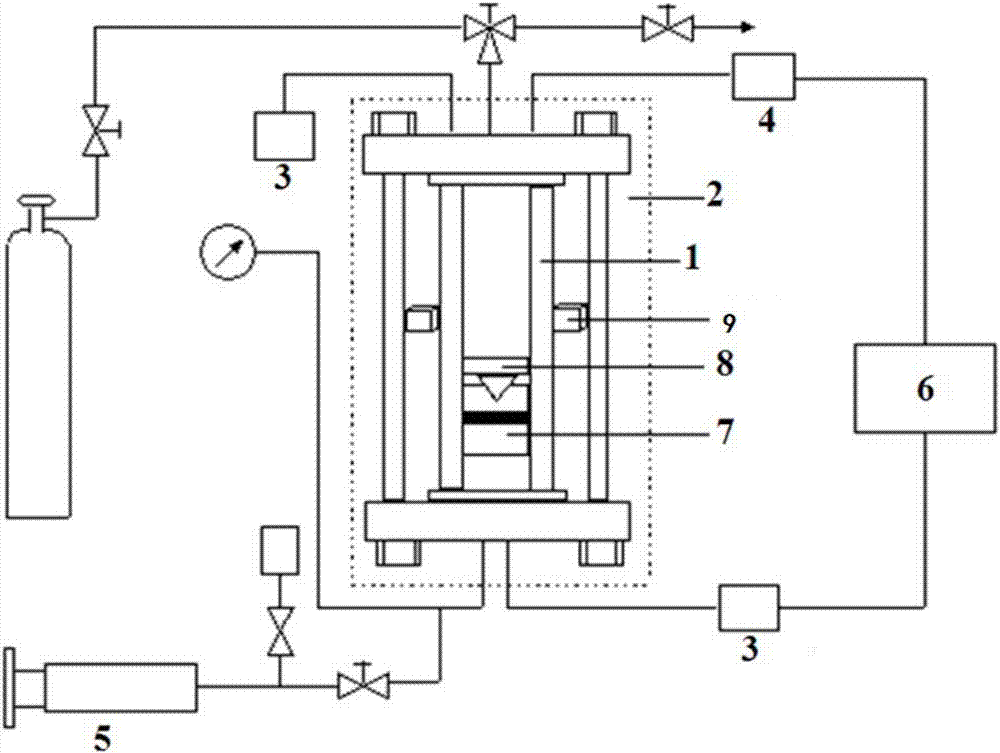

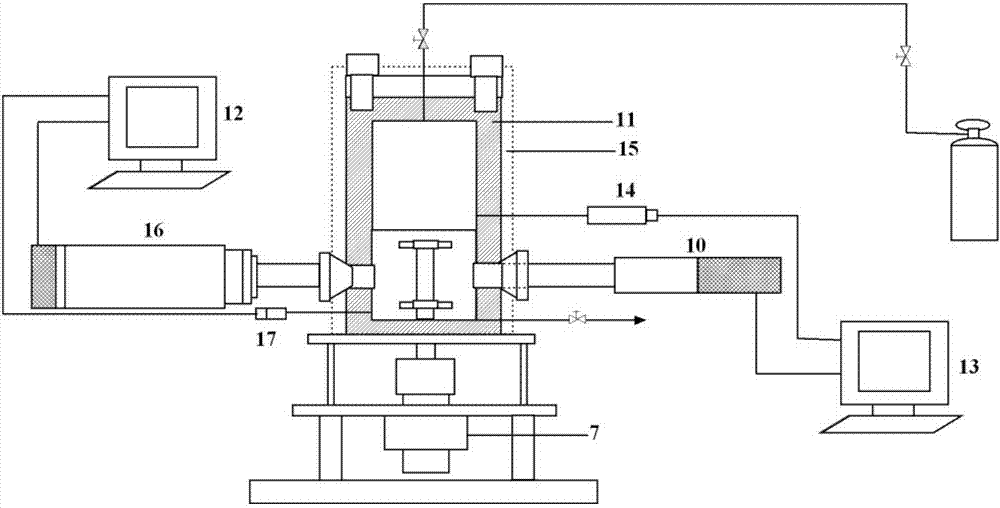

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a class of high-efficiency composite hydrate antipolymerization agent, which consists of (Span20+Tween80), AEO 3 , (TBAB+SDS) and ethanol are obtained by compounding at a mass ratio of 1:1:1:1.

[0044] Apply the above compound hydrate antipolymerization agent to an oil-water system with a water content of 10% (calculated based on the sum of the volumes of water and oil), and the effect of using the compound hydrate antipolymerization agent in this embodiment For evaluation, this embodiment uses the high-pressure sapphire reactor described in Comparative Example 1 for evaluation, and the specific experimental process is as described in Comparative Example 1.

[0045] In this embodiment, the oil-water system in the reactor is composed of 1.5mL deionized water and 13.5mL of -20# diesel oil, that is, the oil-water system with a water content of 10% (based on the sum of the volumes of water and oil), The amount of antipolymerization agent added in ...

Embodiment 2

[0048] This embodiment provides a class of high-efficiency composite hydrate antipolymerization agent, which consists of (Span60+Tween60), AEO 4 , (TBAB+SDS) and diethylene glycol monobutyl ether are obtained by compounding at a mass ratio of 1:1:1:1.

[0049] In this embodiment, the high-pressure sapphire reactor described in Comparative Example 1 is used for evaluation, and the specific experimental process is as described in Comparative Example 1.

[0050] In this embodiment, the oil-water system in the reactor is composed of 1.5ml deionized water and 13.5ml of -20# diesel oil, that is, the oil-water system with a water content of 10% (based on the sum of the volumes of water and oil), The addition amount of the antipolymerization agent in this embodiment is 1.0% of the water mass in the system, and the composition of the experimental gas introduced is shown in Table 1.

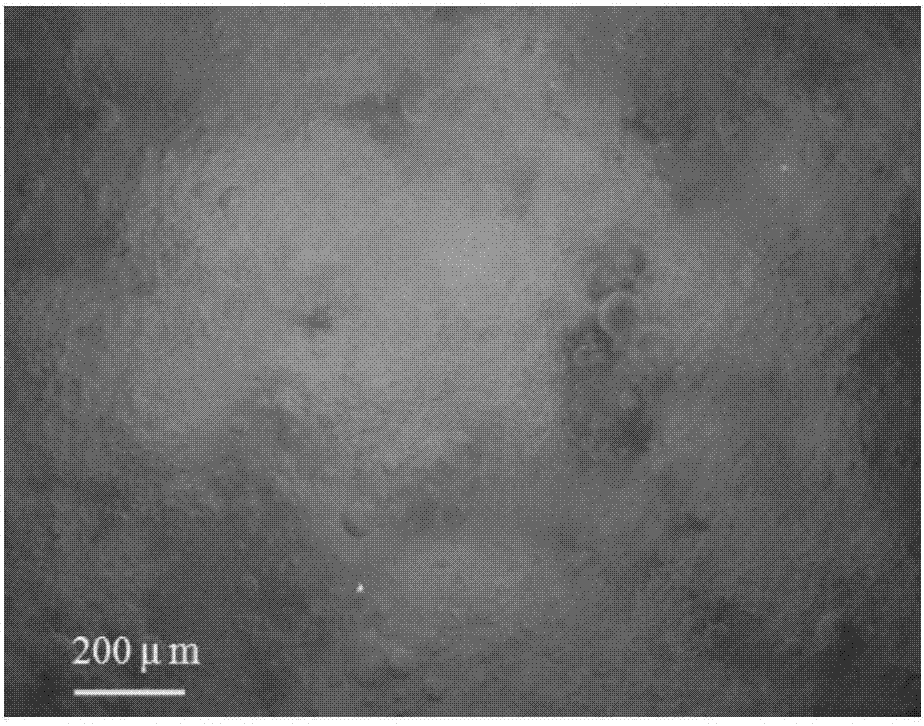

[0051] During the whole experiment process of this example, the hydrate particles were evenly disperse...

Embodiment 3

[0053] This embodiment provides a class of high-efficiency compound hydrate antipolymerization agent, which consists of (Span80+Tween60), AEO 8 , (TBAB+SDS) and ethylene glycol are compounded at a mass ratio of 1:1:1:1.

[0054] In this embodiment, the high-pressure sapphire reactor described in Comparative Example 1 is used for evaluation, and the specific experimental process is as described in Comparative Example 1.

[0055] In this embodiment, the oil-water system in the reactor is composed of 1.5ml deionized water and 13.5ml of -20# diesel oil, that is, the oil-water system with a water content of 10% (based on the sum of the volumes of water and oil), The addition amount of the antipolymerization agent in this embodiment is 1.0% of the water mass in the system, and the composition of the experimental gas introduced is shown in Table 1.

[0056] During the whole experiment process of this example, the hydrate particles were evenly dispersed in the oil phase, and there wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com