Early-strength high-performance polycarboxylic acid water reducer and preparation method thereof

A water-reducing agent, high-performance technology, applied in the field of early-strength high-performance polycarboxylate water-reducer and its preparation, can solve the problem of poor comprehensive performance, initial setting time and final setting of early-strength polycarboxylate water-reducing agent Long time, unable to meet the use requirements and other problems, to achieve the effect of improving the wrapping performance, excellent antifreeze effect, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

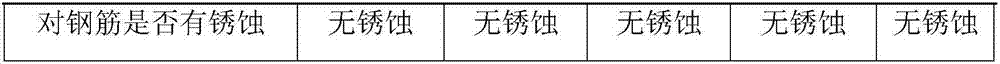

Examples

Embodiment 1

[0022] An early-strength high-performance polycarboxylate water reducer is prepared from the following raw materials in parts by weight: 100 parts of polycarboxylate water reducer, 15 parts of retarder, diethanol monoisopropanolamine maleate 12 parts of ester compound, 8 parts of diethanol monoisopropanolamine, 12 parts of sodium lignosulfonate, 3 parts of 2-ethyl-4-methylimidazole, 1.5 parts of tetradecyltrimethylammonium bromide, 10 parts of sodium metasilicate pentahydrate, 250 parts of water.

[0023] Described, retarder is sodium gluconate.

[0024] As mentioned, the solid content of the polycarboxylate water reducer is 40%.

[0025] Described, diethanol monoisopropanolamine maleate compound is made by following method: add diethanol monoisopropanolamine and maleic anhydride in reactor, add catalyzer, depressurize to 0.4MPa, heating, the temperature is controlled at 95°C, the system is kept at a constant temperature, and the acidity of the system is measured every 1h, a...

Embodiment 2

[0032] An early-strength high-performance polycarboxylate water reducer is prepared from the following raw materials in parts by weight: 100 parts of polycarboxylate water reducer, 13 parts of retarder, diethanol monoisopropanolamine maleate 14 parts of ester compound, 9 parts of diethanol monoisopropanolamine, 10 parts of sodium lignosulfonate, 4 parts of 2-ethyl-4-methylimidazole, 1 part of tetradecyltrimethylammonium bromide, 15 parts of sodium metasilicate pentahydrate, 350 parts of water.

[0033] Described, retarder is sodium hexametaphosphate.

[0034] As mentioned, the solid content of the polycarboxylate water reducer is 40%.

[0035] Described, diethanol monoisopropanolamine maleate compound is made by following method: add diethanol monoisopropanolamine and maleic anhydride in reactor, add catalyzer, depressurize to 0.4MPa, heating, the temperature is controlled at 95°C, the system is kept at a constant temperature, and the acidity of the system is measured every ...

Embodiment 3

[0042] An early-strength high-performance polycarboxylate water reducer is prepared from the following raw materials in parts by weight: 100 parts of polycarboxylate water reducer, 10 parts of retarder, diethanol monoisopropanolamine maleate 16 parts of ester compound, 10 parts of diethanol monoisopropanolamine, 8 parts of sodium lignosulfonate, 5 parts of 2-ethyl-4-methylimidazole, 0.5 parts of tetradecyltrimethylammonium bromide, 20 parts of sodium metasilicate pentahydrate, 450 parts of water.

[0043] Described, retarder is sodium tripolyphosphate.

[0044] As mentioned, the solid content of the polycarboxylate water reducer is 40%.

[0045] Described, diethanol monoisopropanolamine maleate compound is made by following method: add diethanol monoisopropanolamine and maleic anhydride in reactor, add catalyzer, depressurize to 0.4MPa, heating, the temperature is controlled at 95°C, the system is kept at a constant temperature, and the acidity of the system is measured ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com