Ready-mixed plastering mortar prepared from industrial waste liquid slag

A technology for plastering mortar and liquid slag, applied in the field of ready-mixed plastering mortar, can solve the problems such as the immature technology for producing silicon calcium potassium fertilizer, the high cost of steaming bricks with liquid slag, the difficulty of high-speed cotton throwing by a centrifuge, etc. Effects of enrichment and alignment, improved durability, good colloidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

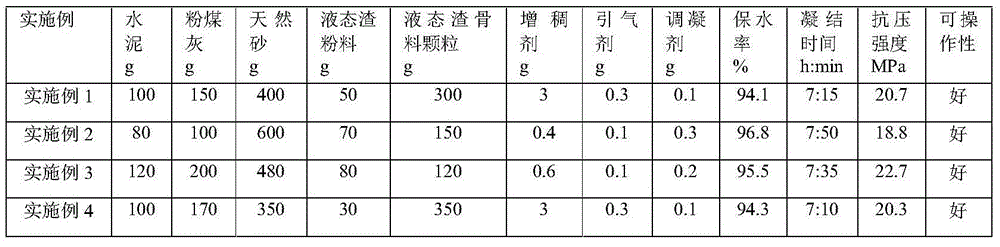

Embodiment 1

[0027] Embodiment 1: A kind of ready-mixed plastering mortar prepared by using industrial waste liquid slag, the ready-mixed plastering mortar is made of cement, fly ash, natural sand, liquid slag powder, liquid slag aggregate particles, thickener , air-entraining agent and coagulation regulator, the above-mentioned raw materials are as follows: 100 parts of cement, 150 parts of fly ash, 400 parts of natural sand, 50 parts of liquid slag powder, 300 parts of liquid slag aggregate particles, 3 parts of bentonite (thickener), 0.3 parts of sodium lauryl sulfate (air-entraining agent), 0.1 part of sodium gluconate (coagulation regulator).

[0028] The cement is a composite Portland cement with a strength grade of 32.5.

[0029] The fly ash is Class II fly ash.

[0030] The natural sand is coarse sand in the gradation zone I.

[0031] The liquid slag powder is 2 to 3% Na 2 SO 4 and 1~2% Ca(OH) 2 Then add the remaining amount of industrial liquid slag; after grinding for 1 to 2...

Embodiment 2

[0037] Embodiment 2: A kind of ready-mixed plastering mortar prepared by using industrial waste liquid slag, the ready-mixed plastering mortar is made of cement, fly ash, natural sand, liquid slag powder, liquid slag aggregate particles, thickener , air-entraining agent and coagulation regulator, the above-mentioned raw materials are as follows: 80 parts of cement, 100 parts of fly ash, 600 parts of natural sand, 70 parts of liquid slag powder, 150 parts of liquid slag aggregate particles, 0.4 part of hydroxypropyl methylcellulose (thickener), 0.1 part of saponin air-entraining agent (air-entraining agent), 0.3 part of sodium tripolyphosphate (coagulation regulator).

[0038] The cement is a composite Portland cement with a strength grade of 32.5.

[0039] The fly ash is Class II fly ash.

[0040] The natural sand is coarse sand in the gradation zone I.

[0041] The liquid slag powder is 2 to 3% Na 2 SO 4 and 1~2% Ca(OH) 2 Then add the remaining amount of industrial liqui...

Embodiment 3

[0047] Embodiment 3: A kind of ready-mixed plastering mortar prepared by using industrial waste liquid slag, the ready-mixed plastering mortar is made of cement, fly ash, natural sand, liquid slag powder, liquid slag aggregate particles, thickener , air-entraining agent and coagulation regulator, the above-mentioned raw materials are as follows: 120 parts of cement, 200 parts of fly ash, 480 parts of natural sand, 80 parts of liquid slag powder, 120 parts of liquid slag aggregate particles, 0.6 part of hydroxyethyl cellulose (thickener), 0.1 part of saponin air-entraining agent (air-entraining agent), 0.2 part of sodium citrate (coagulation regulator).

[0048] The cement is a composite Portland cement with a strength grade of 32.5.

[0049] The fly ash is Class II fly ash.

[0050] The natural sand is coarse sand in the gradation zone I.

[0051] The liquid slag powder is 2 to 3% Na 2 SO 4 and 1~2% Ca(OH) 2 Then add the remaining amount of industrial liquid slag; after g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com