Treatment method of non-ionic surfactant wastewater

A non-ionic surface and treatment method technology, which is applied in the field of non-ionic surfactant wastewater treatment, can solve the problems of introducing excess ions into wastewater, high input costs, cumbersome steps, etc., and achieve excellent treatment effects, low cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

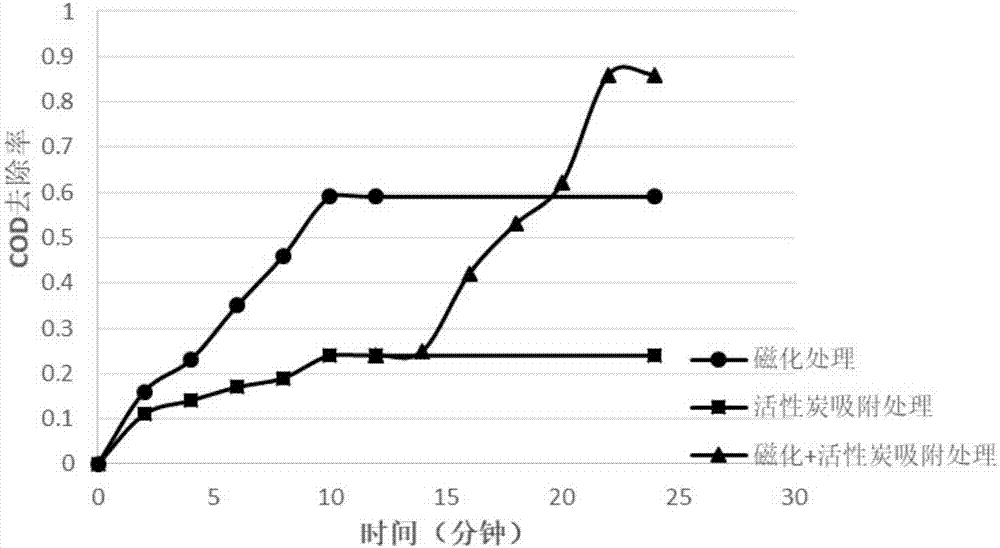

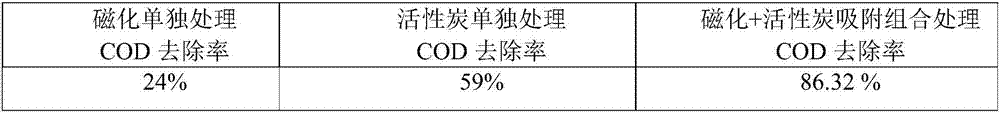

Embodiment 1

[0042] The non-ionic surfactant wastewater in this example comes from the material wastewater of Levima Advanced Materials Co., Ltd. (company address: Mushi Town, Tengzhou City, Shandong Province). The wastewater treatment steps are as follows:

[0043] Step (1) Measure the COD value of the wastewater, the COD value is 8000 mg / L, and adjust the pH value of the wastewater to 5.0.

[0044] Step (2) Construction of the magnetization treatment device: Place two SmCo permanent magnets with the same shape and size in parallel in the magnetization container. town), the structure of the samarium-cobalt permanent magnet is a cube, and its length is 5 centimeters; its width is 2 centimeters; its height is 5 centimeters; the distance of the permanent magnet is adjusted, and the magnetic induction intensity measuring device is used to detect the magnetic induction intensity, and the magnetic induction intensity is measured as 200mT.

[0045] Step (3) Pour the wastewater in step (1) into ...

Embodiment 2

[0071] The source of the nonionic surfactant waste water of the present embodiment is different from the waste water of the factory described in embodiment 1, and the treatment steps are as follows:

[0072] Step (1) Measure the COD value of the wastewater, the COD value is 4000 mg / L, and adjust the pH value of the wastewater to 7.0.

[0073] Step (2) Magnetization treatment device construction: two pieces of samarium cobalt permanent magnets with the same shape and size are placed in parallel in the magnetization container. The structure of the samarium cobalt permanent magnets is a cube with a length of 5 cm; 5 cm; adjust the distance of the permanent magnet, and at the same time use the magnetic induction intensity measuring device to detect the magnetic induction intensity, and the measured magnetic induction intensity is 85mT.

[0074] Step (3) Pour the waste water in the step (1) into a magnetization treatment device for treatment for 12 minutes; measure the COD value of...

Embodiment 3

[0077] The source of the nonionic surfactant waste water of the present embodiment is different from the waste water of the factory described in embodiment 1, and the treatment steps are as follows:

[0078] In step (1), the COD of the wastewater is measured, and the COD is 15000 mg / L, and the pH of the wastewater is adjusted to 4.0.

[0079] Step (2) Magnetization treatment device construction: two pieces of samarium cobalt permanent magnets with the same shape and size are placed in parallel in the magnetization container. The structure of the samarium cobalt permanent magnets is a cube with a length of 5 cm; 5 cm; adjust the distance of the permanent magnet, use the magnetic induction intensity measuring device to detect the magnetic induction intensity, and the measured magnetic induction intensity is 300mT.

[0080] Step (3) Pour the wastewater in step (1) into a magnetization treatment device and treat it for 8 minutes.

[0081] Step (4) build activated carbon adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com