Gas collecting control device for solar casing gas

A technology of control device and casing gas, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of easy fatigue and breakage of spring machine, waste of natural gas resources, environmental pollution, etc., and achieve the goal of overcoming safety hazards and Disadvantages of environmental pollution, energy-saving natural gas resources, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

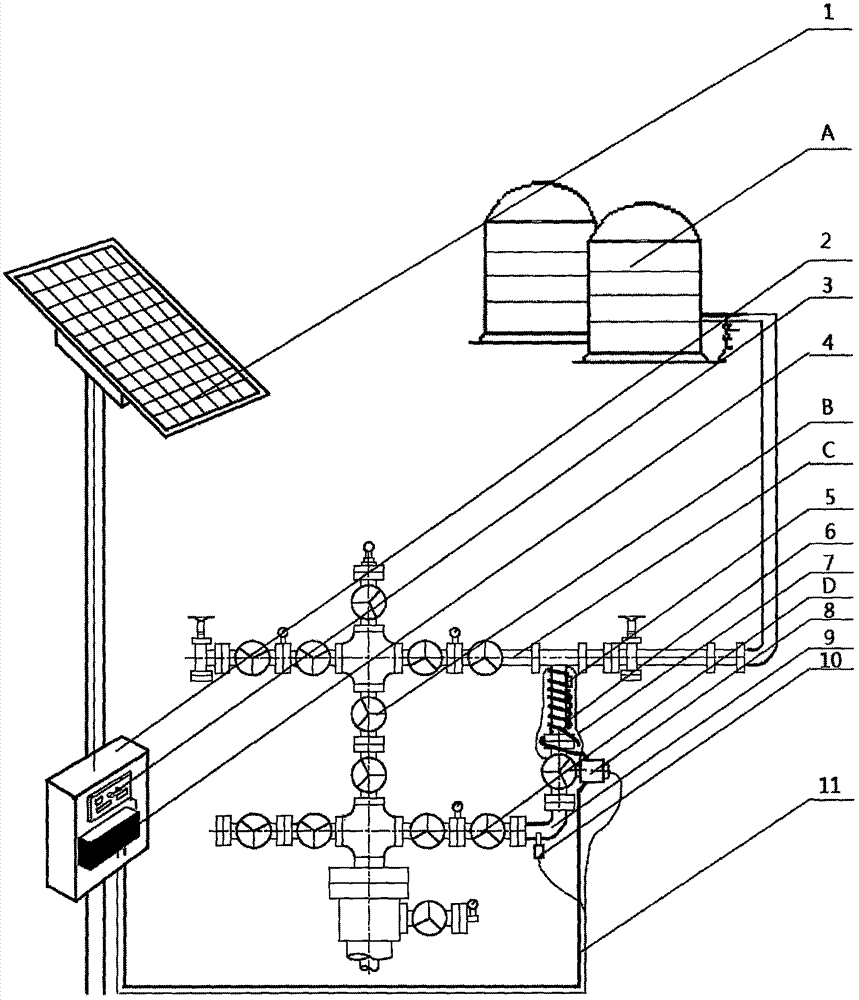

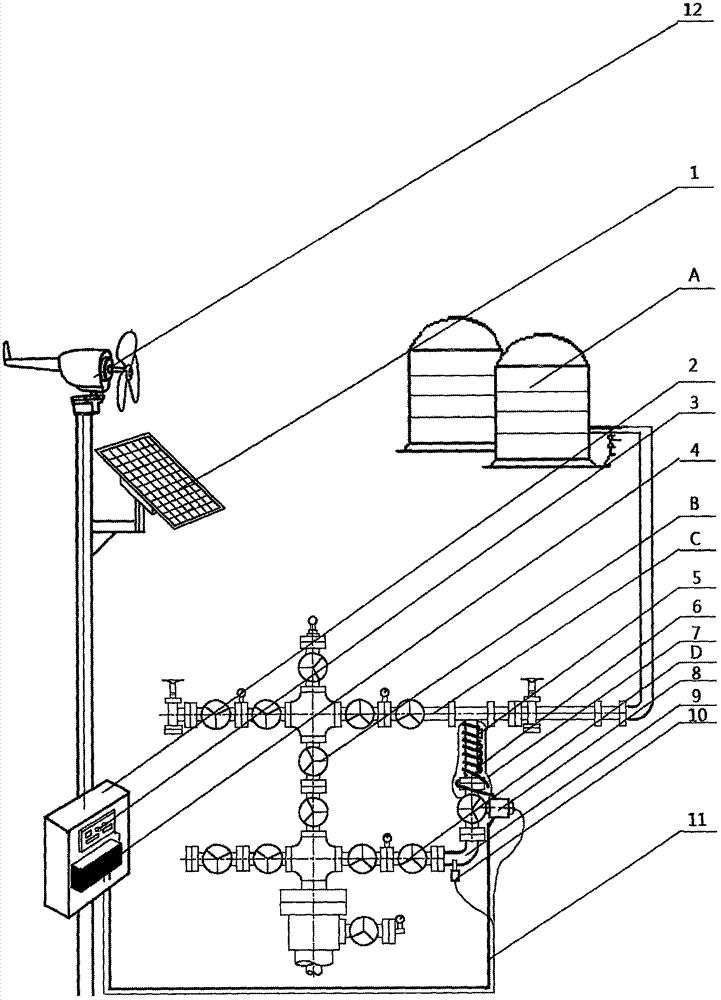

[0011] Such as figure 1 As shown, the present invention is a kind of energy-saving control device for solar energy casing, which consists of a solar panel 1, a control box 2, a control circuit board 3, a storage battery 4, a temperature sensor 5, an electric heating wire 6, a thermal insulation layer 7, It consists of solenoid valve 8, gas collecting manifold 9, pressure sensor 10, electric power and signal cable 11.

[0012] In the figure, A is the large tank of the union station, B is the Christmas tree, C is the tubing manifold, and D is the reservoir casing manifold, all of which are standard petroleum devices.

[0013] Among them: the control circuit board 3 includes a solar cell 1 charging control circuit to the storage battery 4, and the control circuit board 3 is provided with a clock chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com