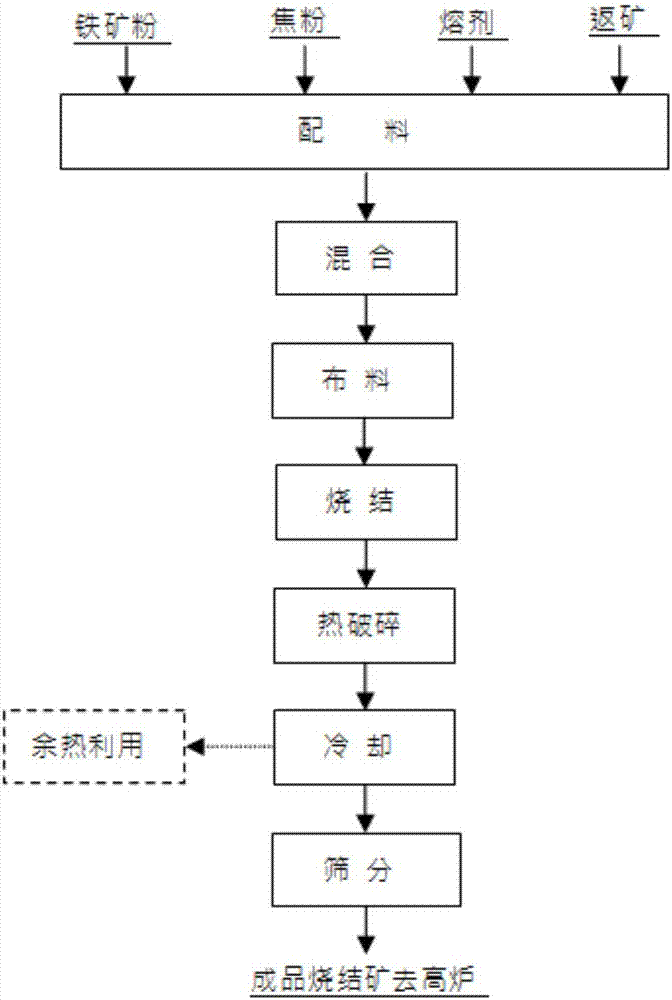

Iron ore pre-reduction sintering method and device

A sintering method and a sintering device technology, which are applied in the field of iron ore sintering, and can solve the problems of accelerating the reduction reaction of iron ore materials and difficult to deal with high CO flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

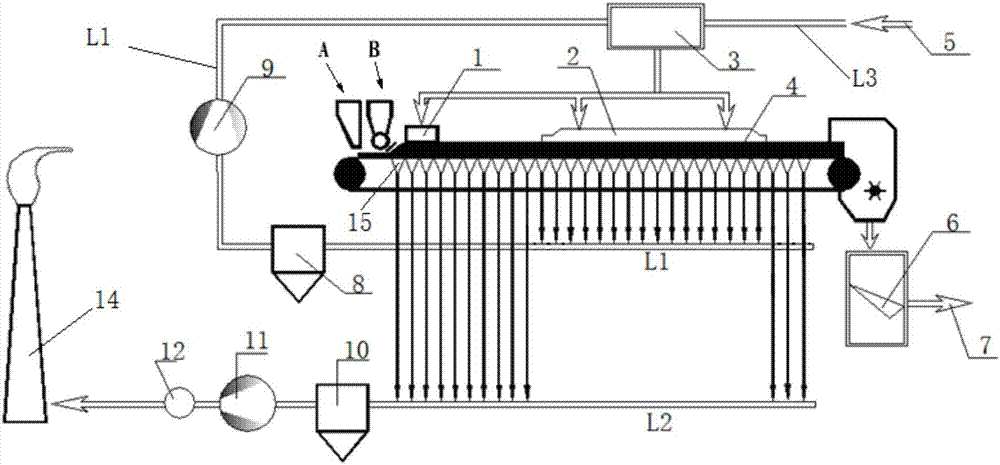

Method used

Image

Examples

Embodiment 1

[0113] A method for pre-reduction sintering of iron ore, the method comprising:

[0114] 1) Preparation of traditional mixture: iron ore powder, flux (it includes the mixture of three raw materials of unslaked limestone, limestone and serpentine; the dosage ratio of these three raw materials makes the control of CaO and SiO in the sinter preparation process 2 The weight ratio is about 1.8:1) to carry out raw material batching, mixing, granulation, obtains traditional mixture (I), wherein the consumption ratio of iron ore powder, flux and coal fuel is 83:12:5;

[0115] 2) Preparation of pre-reduced mixture: mix iron ore powder, additives and coke powder and then pelletize (such as disc pelletizing or briquetting) to obtain pellets (IIa) with internal carbon, wherein: fuel to ore ratio At 0.18:1 (wt), the average pellet diameter is 6 mm;

[0116] The pellet (IIa) with internal carbon is placed in a drum mixer, fuel fine powder and flux are added, mixed, and the outside of the p...

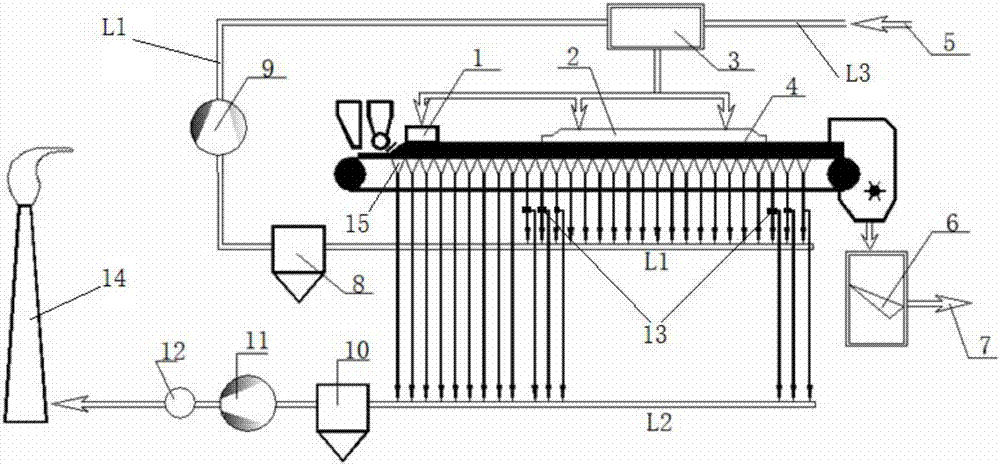

Embodiment 2

[0122] Repeat embodiment 1, only the consumption ratio of iron ore powder, flux and coal fuel in step 1) is 81:15:4; In step 2), the fuel and ore ratio are 0.25:1 (wt) average pellet diameter is 10mm; The mass ratio of pellets with internal carbon, fine fuel powder and flux is 1:0.15:0.01.

[0123] In addition, in addition to including 1) preparation of traditional mixture; 2) preparation of pre-reduced mixture; 3) cloth; 4) sintering, it also includes:

[0124] 5) Oxygen production: use an oxygen generator to separate air to obtain oxygen and nitrogen, in which oxygen is used for flue gas circulation and sintering oxygen distribution, and nitrogen is used for on-board cooling; and the flue gas from the on-board cooling bellows is used for waste heat recovery (waste heat to generate steam or power generation) to be recycled and reused for onboard cooling; and.

[0125] 6) After the sintered sintered cake is crushed, it passes through a hot ore sieve, and the product on the si...

Embodiment 3

[0127] Repeat Example 1, just replace coke powder with pulverized coal, and slaked lime replace quicklime.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com