Dispersion method for multilayer graphene

A multi-layer graphene, graphene dispersion technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as reducing graphene performance, and achieve the goal of maintaining intrinsic characteristics, reducing impact, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

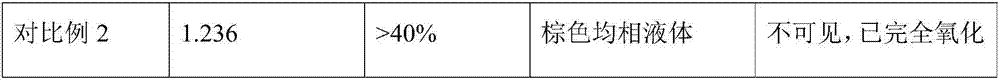

Examples

Embodiment 1

[0032] Mix 10% mass fraction of hydrogen peroxide with 10mol / L sulfuric acid at a volume ratio of 1:5; then add multilayer graphene to the acid solution, the mass ratio of multilayer graphene to acidic oxidation solution is 1:100, ultrasonic Shake for 20min, and heat and stir at 60°C for 2h. After the stirring is completed, the graphene is washed with water to remove acid by natural sedimentation, centrifugation or dialysis, and then the graphene aqueous slurry is obtained.

Embodiment 2

[0034] Mix 5% hydrogen peroxide with 5mol / L sulfuric acid at a volume ratio of 1:3; then add multilayer graphene to the acid solution, the mass ratio of multilayer graphene to acidic oxidation solution is 1:100, ultrasonic Shake for 60 minutes, and heat and stir at 80°C for 4 hours. After the stirring is completed, the graphene is washed with water to remove acid by natural sedimentation, centrifugation or dialysis, and then the graphene aqueous slurry is obtained.

Embodiment 3

[0036] Mix 3% hydrogen peroxide with 3mol / L sulfuric acid at a volume ratio of 1:2; then add multilayer graphene to the acid solution, the mass ratio of multilayer graphene to acidic oxidation solution is 1:1000, ultrasonic Shake for 60 minutes, and heat and stir at 80°C for 6 hours. After the stirring is completed, the graphene is washed with water to remove acid by natural sedimentation, centrifugation or dialysis, and then the graphene aqueous slurry is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com