Manufacturing method of light emitting diode chips and light conversion device

A light-emitting diode and chip technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of low yield rate of LED chips, achieve the effect of improving external quantum efficiency, increasing yield rate, and avoiding chip breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

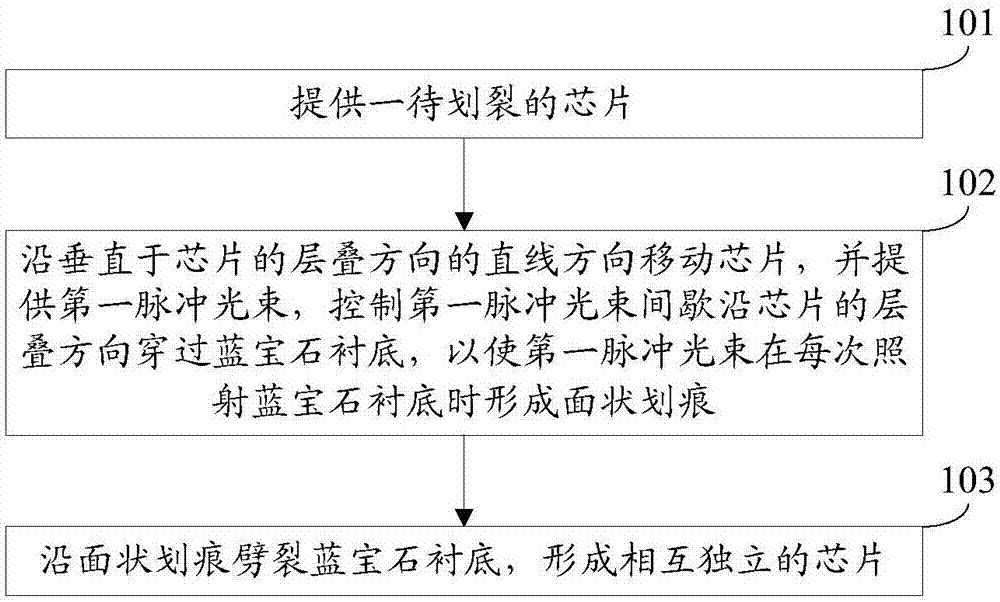

[0041] The embodiment of the present invention provides a method for preparing a light-emitting diode chip, see figure 1 , the preparation method comprises:

[0042] Step 101: Provide a chip to be diced.

[0043] In this embodiment, the chip includes a sapphire substrate and an N-type semiconductor layer, a light-emitting layer, a P-type semiconductor layer, a current blocking layer, a transparent conductive layer, and a P-type electrode stacked sequentially on the sapphire substrate. A groove extending from the P-type semiconductor layer to the N-type semiconductor layer along the stacking direction of the chip is opened, and an N-type electrode is arranged on the N-type semiconductor layer in the groove.

[0044] Specifically, this step 101 may include:

[0045] In the first step, an N-type semiconductor layer, a light-emitting layer, and a P-type semiconductor layer are sequentially grown on a sapphire substrate.

[0046]In the second step, a groove extending from the P-...

Embodiment 2

[0089] An embodiment of the present invention provides a light conversion device used in the preparation method provided in Embodiment 1, see Figure 5 , the device consists of:

[0090] a laser 201, configured to emit a second pulse beam;

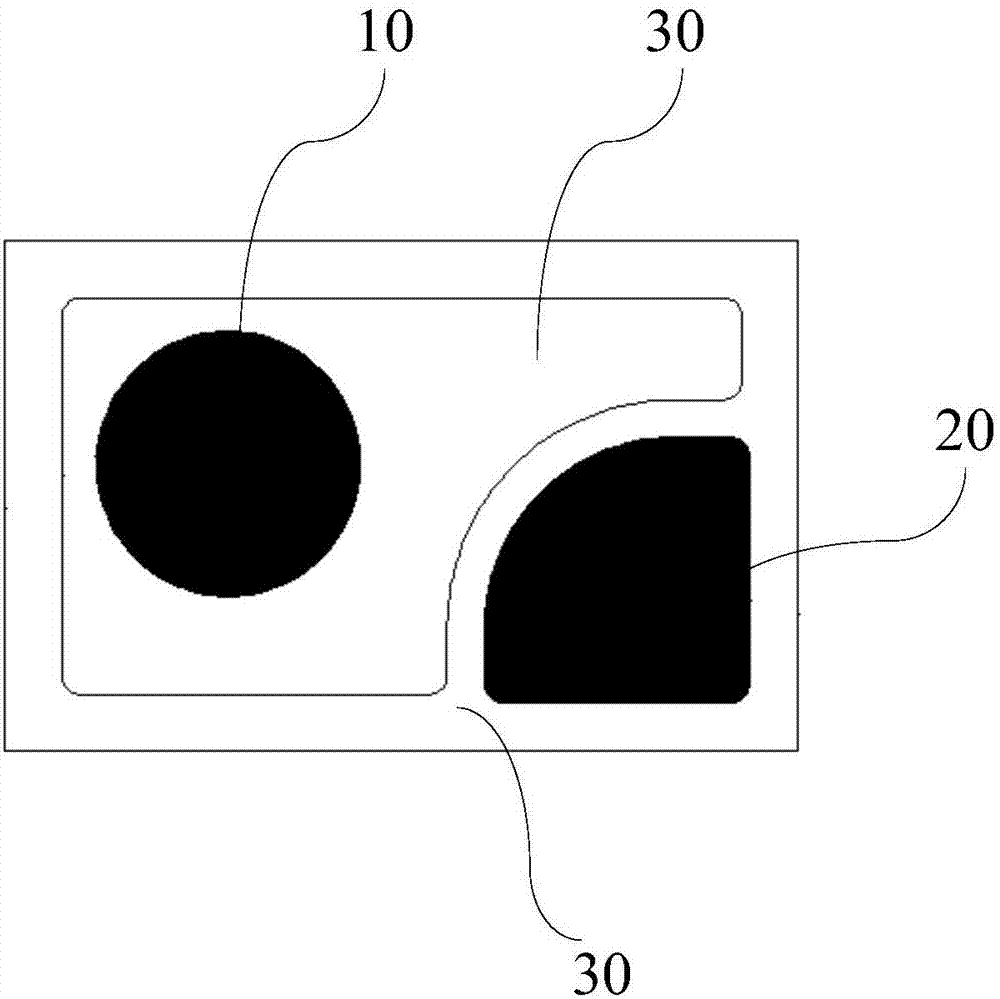

[0091] The lens group 202 is used to diverge the second pulsed beam emitted by the laser 201 into a third pulsed beam, and the cross-sections of the second pulsed beam and the third pulsed beam parallel to the surface of the sapphire substrate provided with the N-type semiconductor layer are both A circle with a constant area, and the cross-sectional area of the second pulsed beam is smaller than the cross-sectional area of the third pulsed beam;

[0092]The filter plate 203 is used to intercept the third pulse beam formed by the lens group 202 into a fourth pulse beam, and the cross section of the fourth pulse beam parallel to the surface of the sapphire substrate provided with the N-type semiconductor layer has a constant area rect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com