Tube distributing structure of lateral steam feeding condenser

A technology of condenser and steam inlet, which is used in steam/steam condensers, lighting and heating equipment, etc. It can solve the problems of unsuitable dual-process or smaller condensers, small high-speed diffusion section of tube bundles, and insufficiently compact structure. , to reduce the resistance, improve the pipe layout rate, and improve the heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and examples.

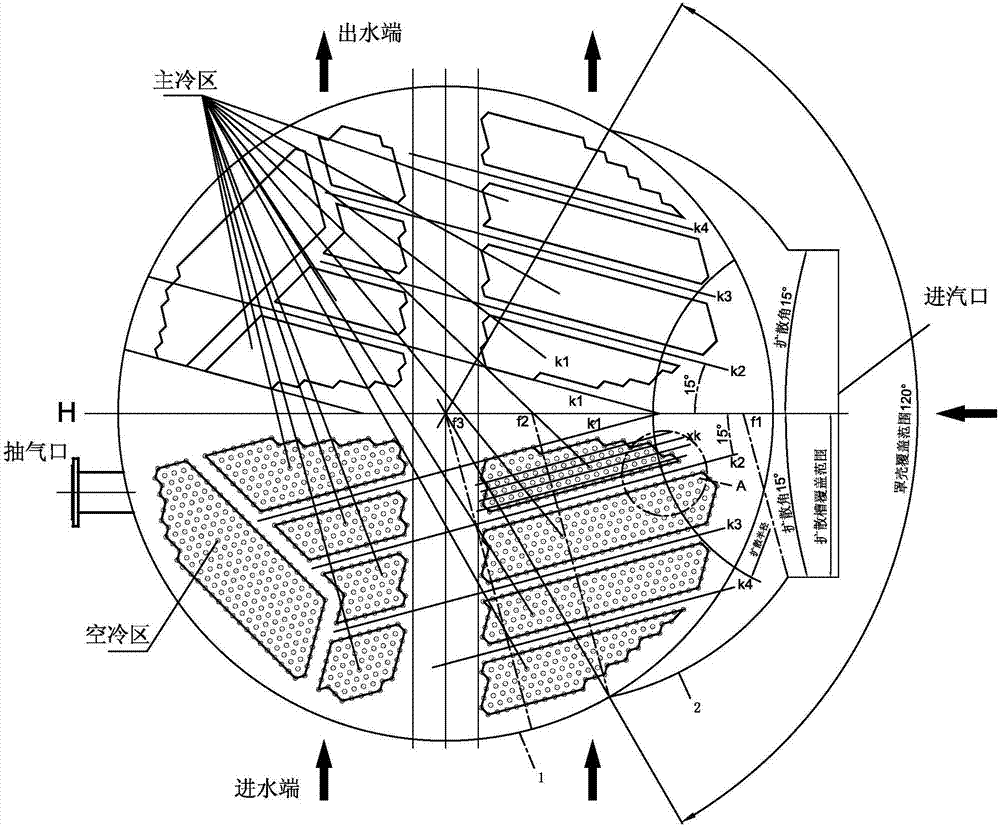

[0020] In this embodiment, 2220 tubes of 20 mm are arranged in the cavity of the condenser with a diameter of 2000 mm, the distance between the tubes is 30 mm, and the two ends of all the tubes are respectively fixed on the tube sheets at both ends of the condenser.

[0021] In the pipe layout structure of the side steam inlet condenser provided by the present invention, the steam inlet of the condenser is located at the right end of the condenser, and several tube bundles ( figure 1 , figure 2 In , each tube bundle is surrounded by a thick double-dot dash line, which contains multiple tubes; for the sake of clarity, some tube bundles are only drawn with thick double-dot dash lines, and the tubes in them are omitted), and the diffusion between the tube bundles is to facilitate the circulation of steam The axes of the adjacent diffuser grooves are all ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com