Pump motor with A isolation tank

A pump motor, isolation tank technology, applied in the direction of pumps, parts of pumping devices for elastic fluids, pump devices, etc., can solve problems such as the limitation of the possibility of pump use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

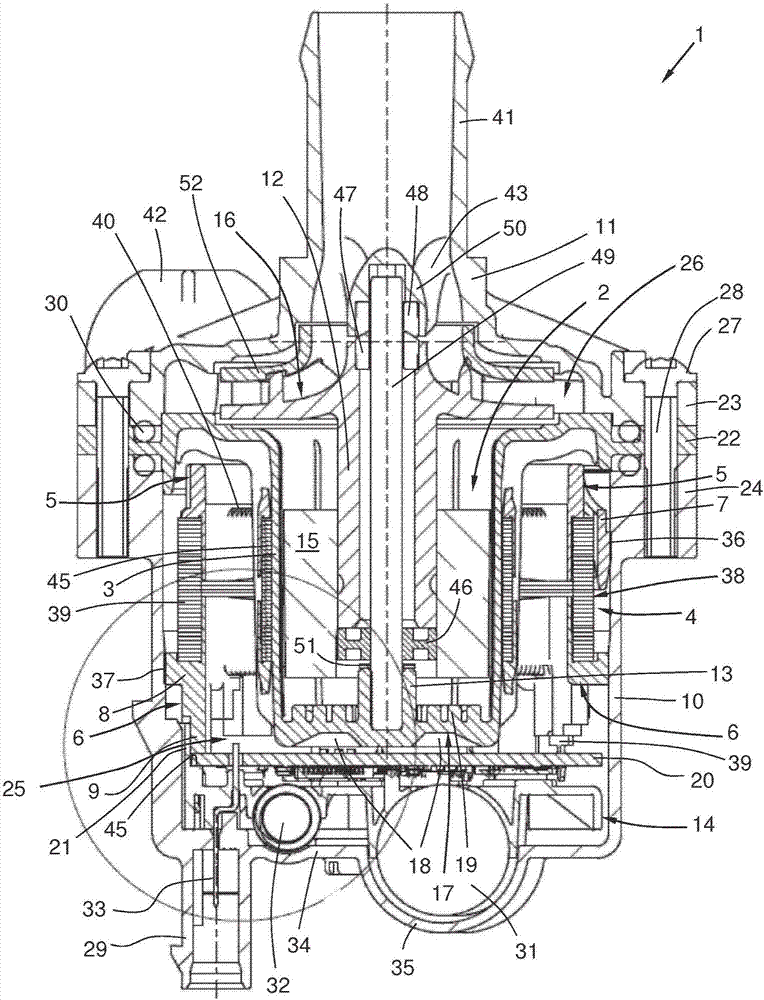

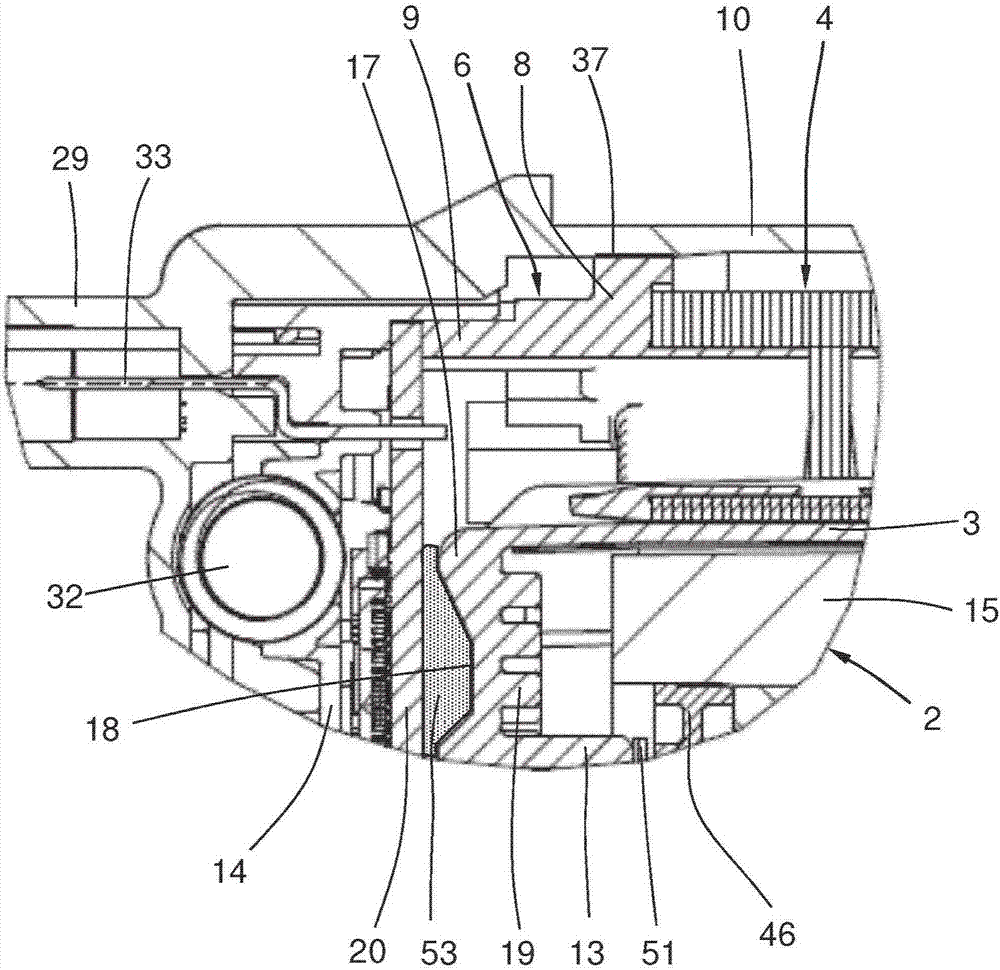

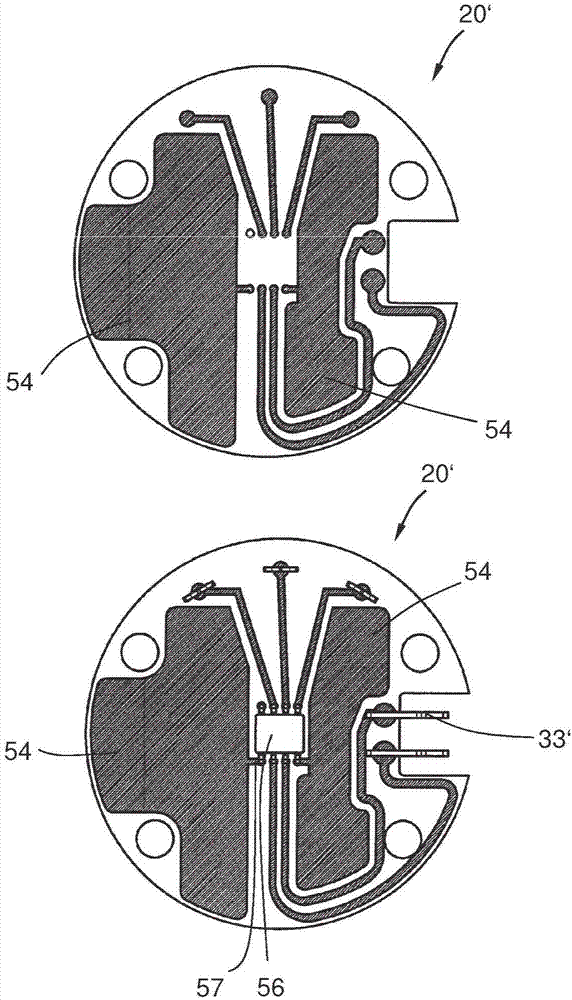

[0020] figure 1 A sectional view of a pump motor 1 according to the invention is shown with a wound stator 4 , a permanent magnet rotor 2 , an insulating pot 3 , a pump head 11 , a circuit board 20 , a carrier plate 14 and a motor housing 10 . The stator 4 , the circuit board 20 and the carrier plate 14 are located in the dry chamber 25 . The permanent magnet rotor 2 is mounted rotatably in the wet chamber 26 about an axis 49 which is fixedly mounted on the one hand in the insulating tank 3 and on the other hand in the pump head 11 . The stator 4 comprises a stator lamination stack 38 , insulating elements 5 , 6 and a stator winding 40 . The fastening projections 7 , 8 extend radially away from the insulating elements 5 , 6 . The fastening projections 7 , 8 have welding regions 36 , 37 at which the fastening projections are firmly connected to the motor housing 10 . The second insulating element 6 is equipped with an axially inserted winding connection end 39 which is mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com