Device and method for casing leak detection

A casing and leakage point technology, applied in the field of casing leakage detection devices, can solve the problems of misjudgment of the missing section, high work intensity of construction personnel, slow measurement speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In order to achieve the above object, the technical scheme adopted in the present invention is:

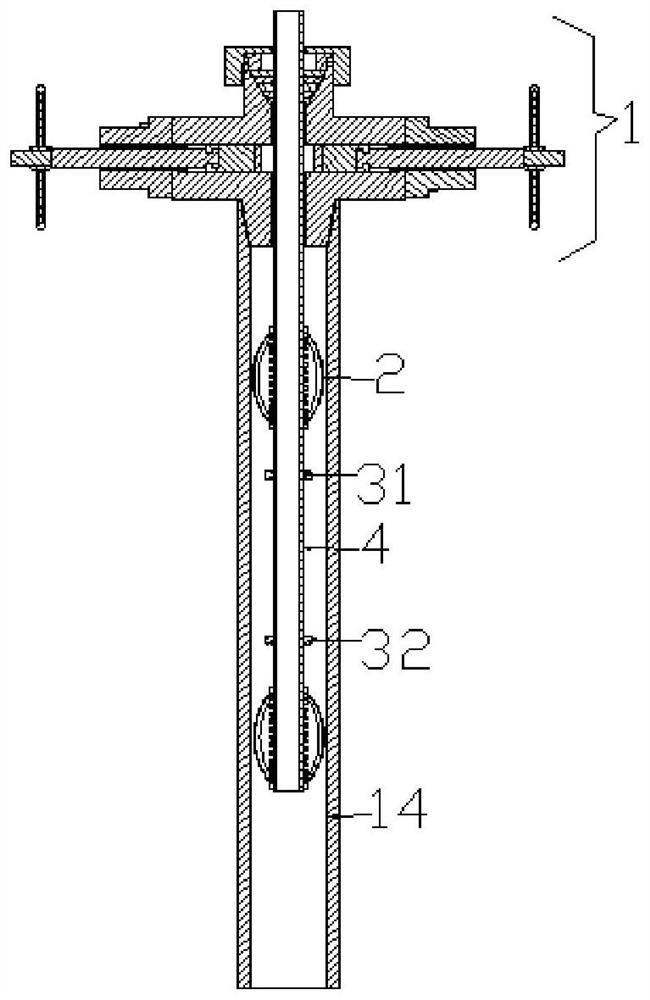

[0056] Such as Figure 1-Figure 8 As shown in Fig. 1 , a casing leak detection device includes a wellhead packer 1, a coiled tubing centralizer 2 and a data measuring instrument 3. The wellhead packer 1 is connected to the wellhead casing 14, and the lower end of the coiled tubing centralizer 2 and the The data measuring instruments are all fixed on the coiled tubing 4 .

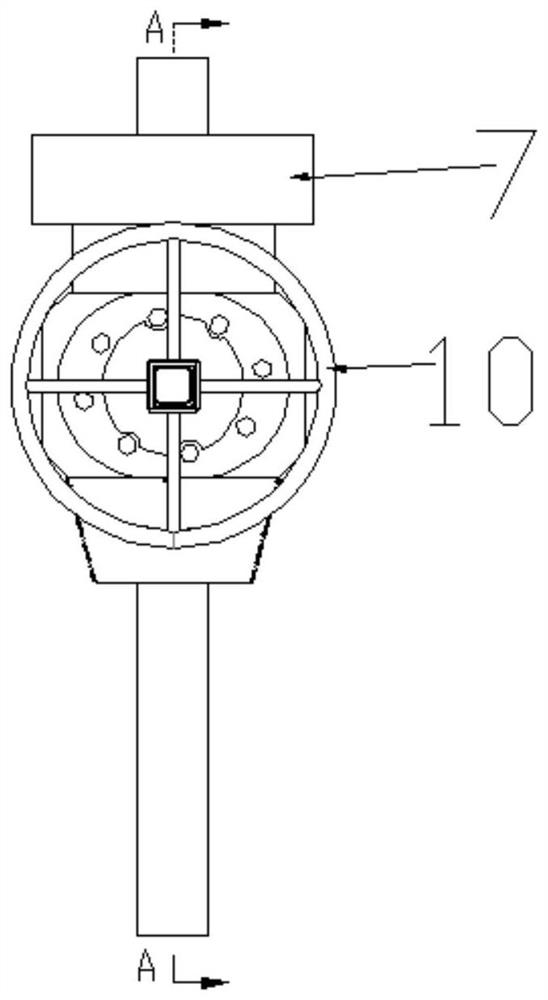

[0057] The wellhead packer 1 includes an upper sealing device and a lower sealing device. The upper sealing device includes a sealing rubber ring 5, and the sealing rubber ring 5 is provided with a top plate 6 and a sealing cover plate 7, wherein the sealing rubber ring 5 is conical, and the sealing rubber ring 5 main sealing functions. The conical sealing rubber ring 5 is squeezed by the downward force of the upper sealing cover plate 7, causing the conical sealing rubber ring 7 to be compressed downwa...

Embodiment 2

[0075] Different from Embodiment 1, the detection method of the casing leak detection device comprises the following steps:

[0076] Step (1). Before the device goes into the well, check whether the connection of the ultrasonic data measuring instrument is normal, whether the information transmission is smooth, and whether the wellhead sealing device is intact. After the device is connected, lower the ultrasonic data measuring instrument to the specified depth.

[0077] Step (2). Then start the wellhead packer device 1, tighten the sealing cover 7 above the conical sealing rubber ring 5, and at the same time manually close the lower sealing device, that is, rotate the manual turntable 10 clockwise to drive the linkage screw 11 to rotate, Thus, the gate 8 is closed to ensure the sealing of the wellhead;

[0078] Step (3). After the wellhead is sealed, the other end of the coiled tubing is connected to the water injection vehicle, and water is injected into the casing 14 throug...

Embodiment 3

[0083] The difference from Embodiment 1 is that the number of coiled tubing centralizers 2 is multiple, and multiple coiled tubing centralizers 2 are arranged at intervals up and down, and the coiled tubing centralizers 2 have a symmetrical structure up and down. The coiled tubing centralizer 2 is in the shape of a lantern as a whole, including an upper fixing ring 15 and a lower fixing ring 16. The lower fixing ring 16 is fixed on the outer wall of the coiled tubing 4 and moves up and down with the coiled tubing 4. The upper fixing ring 15 is not fixed on the outer wall of the coiled tubing 4 superior. The upper fixing ring 15 and the lower fixing ring 16 are connected by a spring 12, and the inner diameter of the upper fixing ring 15 and the lower fixing ring 16 allows the coiled tubing 4 to pass through. In addition, the upper fixing ring 15 and the lower fixing ring 16 are also made of four tougher steel The strips 13 are connected, and under the contraction of the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com