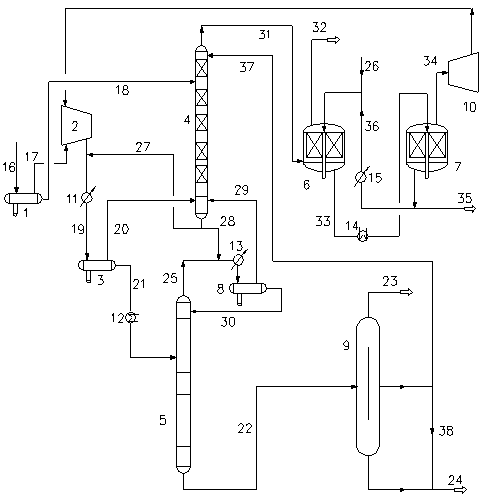

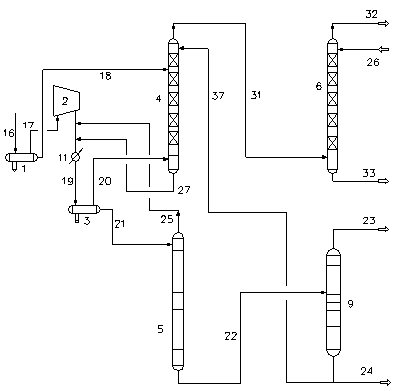

Absorption stabilization process and system

An absorption stabilization system and absorption stabilization technology, applied in the petroleum industry, gas mixture processing, hydrocarbon oil treatment products, etc., can solve problems such as economic losses, and achieve the effects of reducing process energy consumption, reducing circulation, and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Taking a 500,000-ton / year FCC-type catalytic cracking unit absorption stabilization system in China as an example, the ASPEN PLUS process simulation software is used to simulate the process of the present invention, and catalytic diesel is used as the absorbent. The key process parameters are as follows: the outlet of the rich gas compressor The pressure is 1.4 MPa, the operating temperature of the desorption gas balance tank is 40 °C, the absorption tower bottom liquid entering the desorption gas balance tank accounts for 40 wt% of the total liquid phase output at the bottom of the absorption tower, the operating temperature of the rich gas balance tank is 40 °C, and the rich gas balance tank is The liquid-phase heat exchange in the gas balance tank reaches 80°C and enters the desorption tower. The absorption tower is equipped with an intercooler and the return tower temperature is 35°C. The ethane content in the deethanized gasoline at the bottom of the desorption tower...

Embodiment 2

[0048]Compared with Example 1, the difference is that the mixture of 1-butyl-3-methylimidazolium hexafluoroborate and sodium acetate (sodium acetate is 5wt%) is used as absorbent, and the key process parameters are as follows: The outlet pressure of the compressor is 1.4 MPa, the operating temperature of the desorption gas balance tank is 40 ℃, the absorption tower bottom liquid entering the desorption gas balance tank accounts for 40wt% of the total liquid phase output at the bottom of the absorption tower, and the operating temperature of the rich gas balance tank is 40 ℃ , the rich gas balance tank liquid-phase heat exchange to 80 ℃ enters the desorption tower, the absorption tower is equipped with an intercooler and the return temperature of the tower is 35 ℃, the ethane content in the deethanized gasoline at the bottom of the desorption tower is 0.1wt%, and the absorption amount of light gasoline is supplemented 12 t / h. The internal circulation of the absorbent is 30 t / h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com