Efficient spray gun structure for coating machine

A coating machine and high-efficiency technology, which is applied in the direction of making medicines into special physical or taking forms, spraying devices, spraying devices, etc., can solve the problems of inconvenient assembly and maintenance, and achieve reasonable structural design and high temperature resistance Excellent, solve the effect of inconvenient assembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

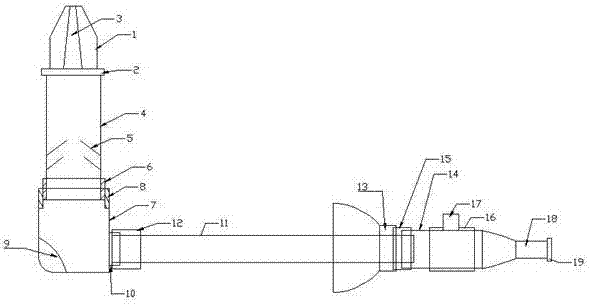

[0018] Such as figure 1 The present invention shown provides a high-efficiency spray gun structure applied to a coating machine, including a nozzle seat 1, and a positioning sleeve 2 arranged at the end of the nozzle seat 1, and is arranged in the nozzle seat 1 and connected to the positioning sleeve 2 at one end The spray head 3, and the first conduit 4 connected to one side of the positioning sleeve 2, and the threaded connection ring 6 arranged at one end of the first conduit 4, and the connection guide joint 7 connected with the first conduit 4, wherein the connection guide The joint 7 is provided with an auxiliary threaded connection ring 8 used in conjunction with the threaded connection ring 6, a first connection sleeve 10 arranged on one side of the connection guide joint 7, and a second conduit 11 connected with the first connection sleeve 10 , and the auxiliary connection sleeve 12 that is arranged on the second conduit 11 and is connected with the first connection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com