Stainless steel vibration motor with recirculating cooling water system

A technology of circulating cooling water and vibrating motors, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of shortening the service life of the motor, affecting the normal operation of the motor, affecting the service life of the motor, etc., and achieving a long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

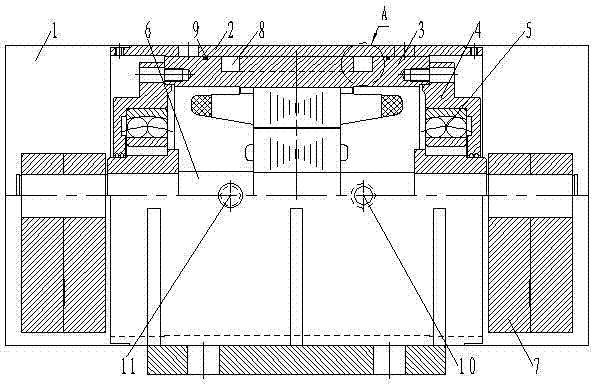

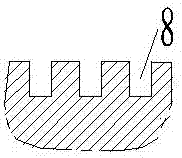

[0013] The technical scheme of the present invention is described in detail in conjunction with the accompanying drawings, a stainless steel vibration motor with a circulating cooling water system, including a stainless steel windshield 1, a stainless steel cylindrical shell 2, a cylindrical inner shell 3, an end cover 4, a bearing 5, and a rotor The shaft 6 and the eccentric block 7, wherein the bearing 5 is embedded in the bearing chamber of the end cover 4, the rotor shaft 6 is installed inside the cylindrical inner shell 3 and the two sides of the rotor shaft 6 are respectively fixed on the bearing 5 and pass through the The end cover 4 and the two ends of the rotor shaft 3 are fixed with eccentric blocks 7 through keys, and the outer wall of the cylindrical inner shell 3 is provided with a spiral flow channel 8 along the circumferential direction, and the outer walls of the cylindrical inner shell 3 on both sides of the spiral flow channel 8 are respectively There is a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com