Vehicle-inside noise indoor testing device and testing method thereof

A technology for interior noise and testing devices, which is applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of indoor analog testing devices without interior noise, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

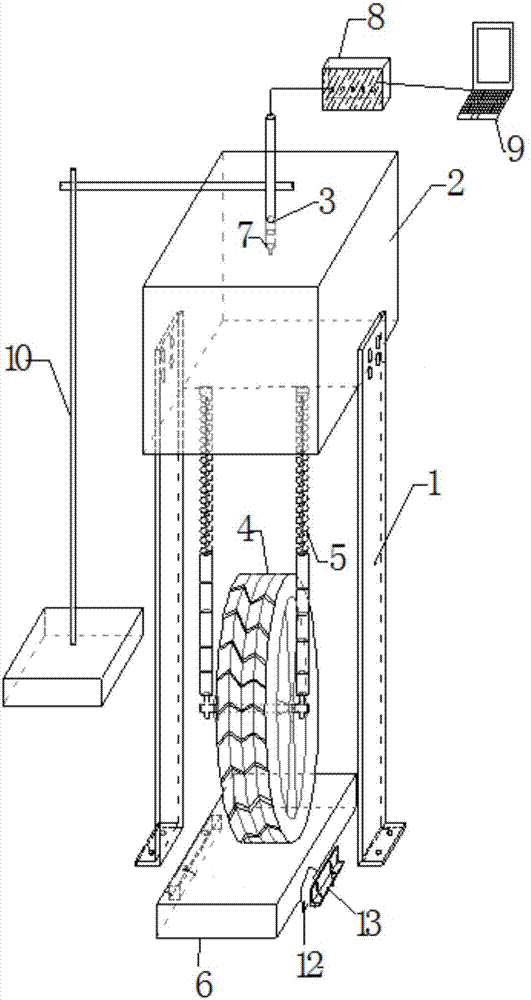

[0024] Such as figure 1 As shown, a kind of indoor noise test device in the car comprises a closed type test cavity 2 and a support bracket 1 for supporting the test cavity 2. The lower end of the test cavity 2 is connected with a test tire 4 through a spring support 5, and the test tire 4 A fixed pavement test piece 6 is provided below, and a sound test hole 3 for installing a sound sensor 7 is opened on the test cavity 2, and the sound sensor 7 is connected to a computer 9 through a multi-channel distributor 8.

[0025] The side of the test cavity 2 is provided with an observation window, the height of the test cavity 2 on the support frame 1 is adjustable, and the lower end of the support frame 1 is fixed on the ground; the sound sensor 7 is placed in the air through the sound test hole 3 on the test cavity 2 The cavity is used to collect the noise caused by the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com