Multi-axis linkage visual and laser combined type non-contact measurement device and measurement method

A non-contact measurement, multi-axis linkage technology, used in measurement devices, optical devices, instruments, etc., can solve the problems of difficult to measure the geometric dimensions of complex workpieces, only measure plane dimensions, and difficult to match automatic production lines, and achieve surface quality. Low requirements, high measurement consistency, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

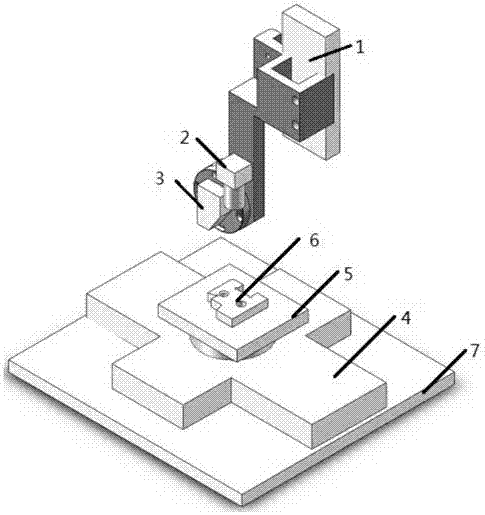

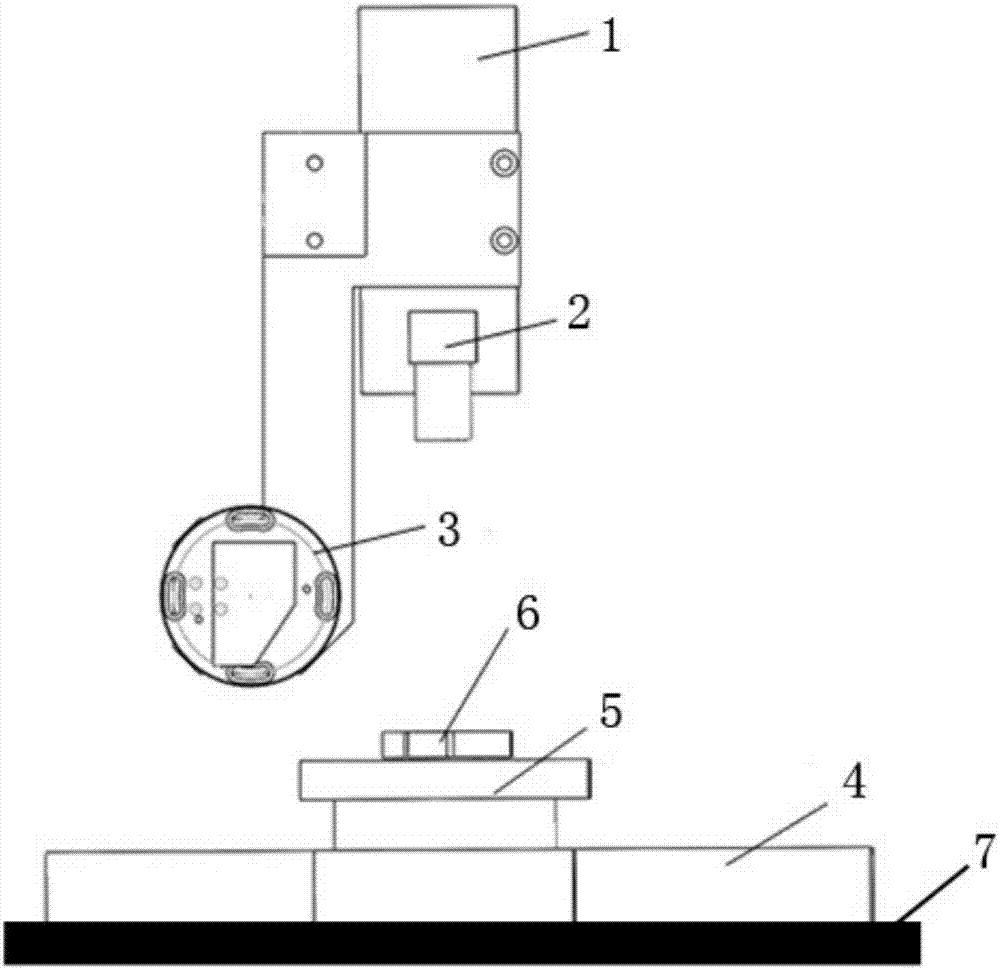

[0023] Such as Figure 1-2 As shown, it includes an up and down lifting mechanism 1, a visual inspection device 2, a non-contact distance detection device 3, a two-axis moving platform 4, a workpiece placement turntable 5, a workpiece to be tested 6, and a base 7.

[0024] The visual inspection device includes a set of high-definition cameras and a set of low-distortion wide-range lenses. The visual inspection device is located above the workpiece turntable, and takes pictures of the workpiece from top to bottom to obtain the outline size of the workpiece.

[0025] The non-contact distance detection device consists of a non-contact laser sensor mount, a non-contact laser sensor, and an angle adjustment shaft. The non-contact laser sensor is installed on the angle adjustment shaft, which can adjust the measurement angle; the angle adjustment shaft is installed on the senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com