Micro-negative-pressure low-temperature drying device and drying process thereof

A drying device and micro-negative pressure technology, which is applied in the direction of drying gas arrangement, heating device, and drying solid materials, can solve the problems of material damage, high energy consumption, and low drying efficiency, so as to reduce operating energy consumption and improve operating efficiency. Energy efficiency, effect of reducing heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

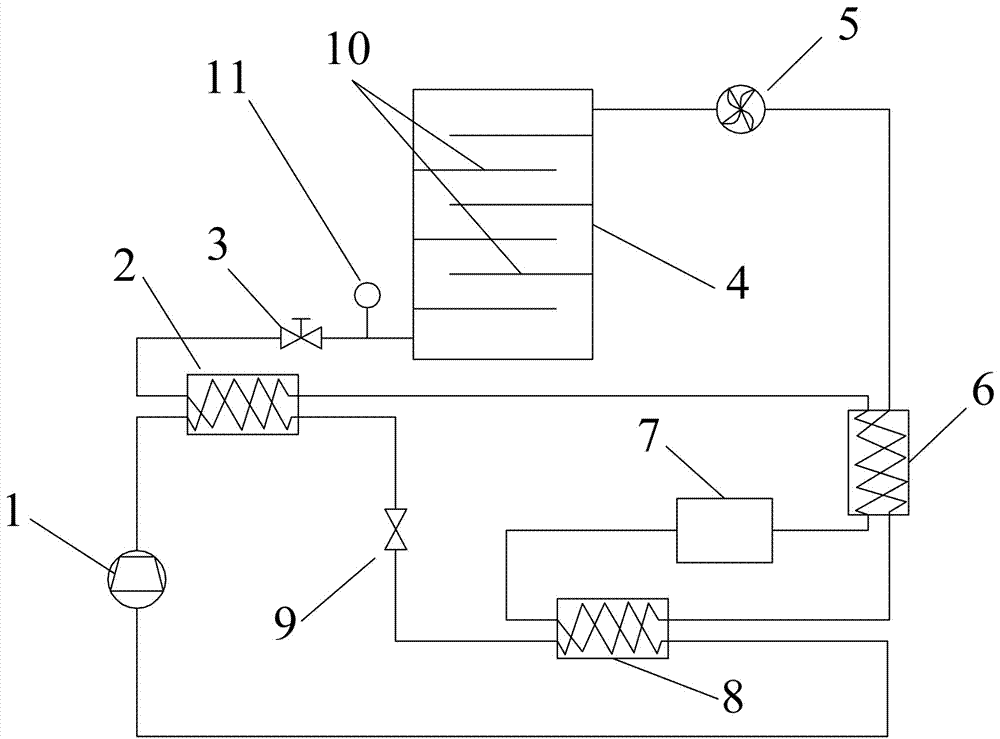

[0033] Such as figure 1 As shown, a micro-negative pressure low-temperature drying device, which includes a drying chamber 4, the inside of the drying chamber 4 is provided with a drying plate 10, the bottom of the drying chamber 4 communicates with the internal condenser 2 of the heat pump unit, and the heat pump unit The internal condenser 2 is simultaneously connected with the internal compressor 1 of the heat pump unit, the internal evaporator 8 of the heat pump unit, and the gas plate heat exchanger 6; the top of the drying chamber 4 is connected with the gas plate heat exchanger 6 through a circulating fan 5; A dehumidifier 7 is also installed between the internal evaporator 8 of the heat pump unit and the gas plate heat exchanger 6; an air duct regulating valve 3 and a pressure vacuum gauge are installed on the pipeline between the internal condenser 2 of the heat pump unit and the drying chamber 4 11. A throttling expansion valve 9 inside the heat pump unit is installe...

Embodiment 2

[0042] The drying process of any micro-negative pressure low-temperature drying device includes the following steps:

[0043] Step1: The low-temperature and low-humidity circulating airflow enters the drying chamber 4 to quickly absorb moisture and dry the materials to be dried evenly arranged on the drying trays 10 of each layer;

[0044] Step2: The circulating air flow absorbs moisture and dries the material and becomes a hot and humid circulating air flow, and leaves the drying chamber under the suction of the circulating fan 5, and enters the gas plate heat exchanger 6 and the circulating air flow after the secondary dehumidification in the second stage Perform heat exchange to achieve pre-cooling of the hot and humid circulating air leaving the drying chamber;

[0045]Step3: The circulating air flow after precooling leaves the gas plate heat exchanger 6 and enters the internal evaporator 8 of the heat pump unit. The heat released in the evaporator greatly reduces the temp...

Embodiment 3

[0049] Furthermore, the micro-negative pressure low-temperature drying device and its drying process are used to efficiently dry high-value-added materials that are extremely sensitive to drying temperature and cannot destroy their active ingredients.

[0050] The preferred scheme adopts a micro-negative pressure low-temperature drying device and its drying process for efficient drying of Chinese herbal medicines, health care products, seeds, high-grade agricultural products and seafood products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com