An AC-DC five-degree-of-freedom cone-spherical hybrid magnetic bearing for a vehicle flywheel battery

A hybrid magnetic bearing and flywheel battery technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problem of unavoidable gyroscopic effect of vehicle-mounted flywheel batteries, and achieve the goal of suppressing gyroscopic effect, reducing volume and mass, and reducing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

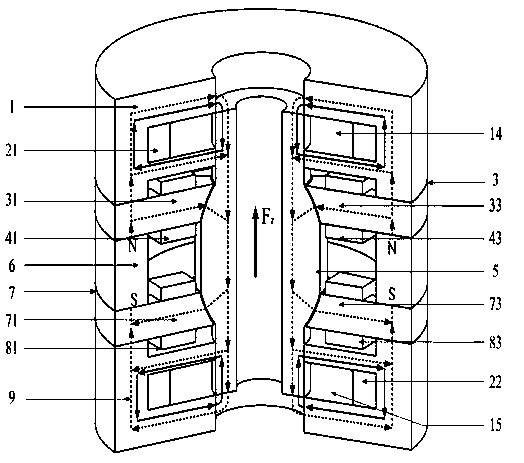

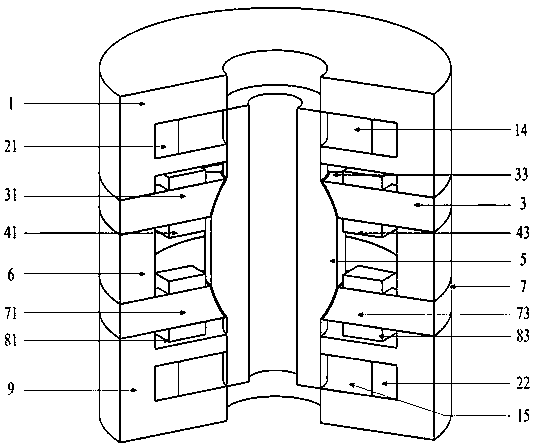

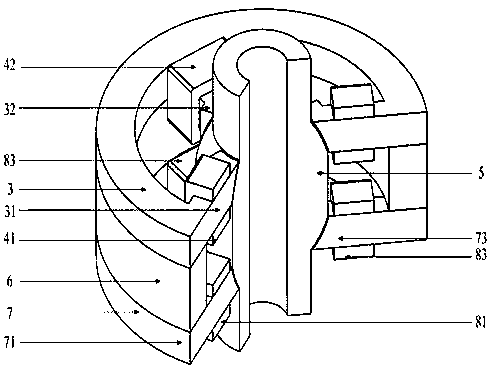

[0026] see figure 1 , the middle of the present invention is the rotor 5, and the radial stator and the axial stator are coaxially sleeved outside the rotor 5.

[0027] see figure 1 , figure 2 and image 3 As shown, the radial stator is composed of an upper radial stator 3 and a lower radial stator 7 , and the upper radial stator 3 and the lower radial stator 7 are coaxially arranged along the axial direction of the rotor 5 and arranged symmetrically up and down in the axial direction. The yokes of the upper radial stator 3 and the lower radial stator 7 are coaxially arranged up and down along the axial direction of the rotor 5, and the yokes of the upper radial stator 3 and the yokes of the lower radial stator 7 are evenly arranged three times along the circumferential direction. radial stator poles, respectively three upper radial stator poles 31, 32, 33 and three lower radial stator poles 71, 72, 73, three upper radial stator poles 31, 32, 33 and three lower The radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com