Sealing and blocking device and method for geothermal holes only extracting heat rather than water

A plugging device and geothermal technology, applied in earthwork drilling, sealing/isolation, wellbore/well parts, etc., can solve problems such as drinking water pollution, achieve good fluidity, good plugging effect, and good construction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

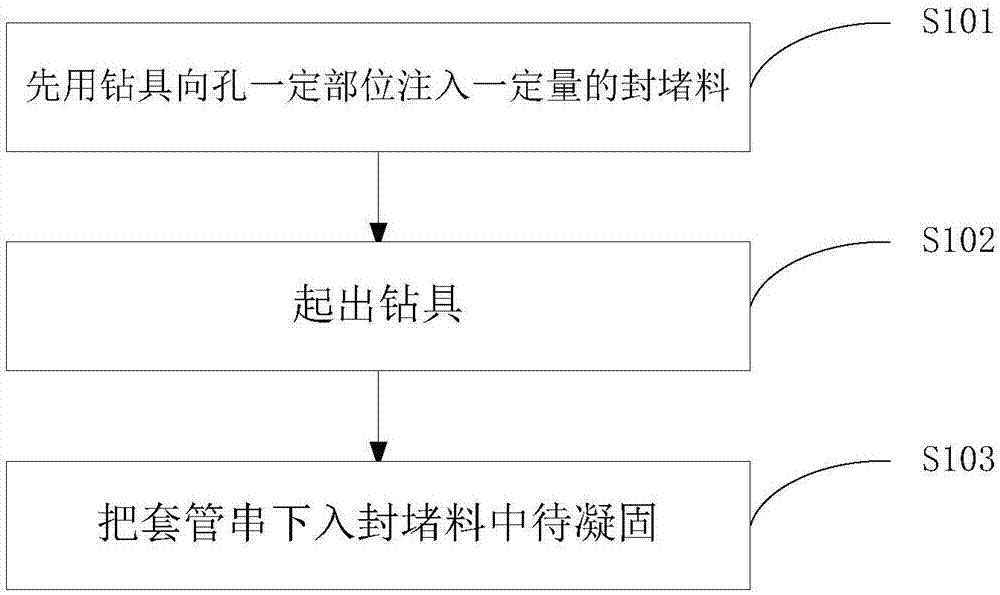

[0057] As a preferred embodiment of the present invention, the preparation method of the plugging material includes:

[0058] Step 1: Take 60-80 parts of Portland cement clinker, 10-20 parts of sulphoaluminate cement, 3-6 parts of bentonite, 0.2-0.5 parts of hydroxyethyl cellulose ether, and 30-20 parts of polymer emulsion according to mass percentage. 40 parts, 3-5 parts of plasticizer, 2-3 parts of defoamer, 0.5-1 part of thickener PRM-300, 20-25 parts of 8# quartz sand; mix and stir evenly to obtain an inorganic precipitation system for use ;

[0059] Step 2, in parts by mass, take 50-90 parts of resin, 0.5-4 parts of accelerator, 10-30 parts of first filler, and 10-30 parts of second filler; mix and stir evenly to obtain a polymer jelly system for use ;

[0060] Step 3: Take the inorganic precipitation system and the polymer jelly system at a ratio of 1:2 to 3.5 by volume.

[0061] As a preferred embodiment of the present invention, after the plugging material is prepar...

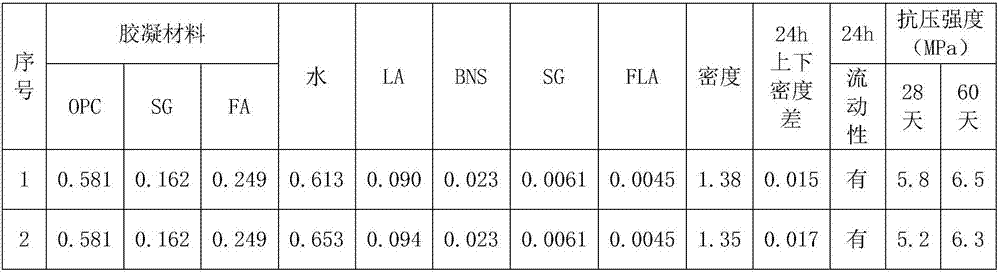

Embodiment 1

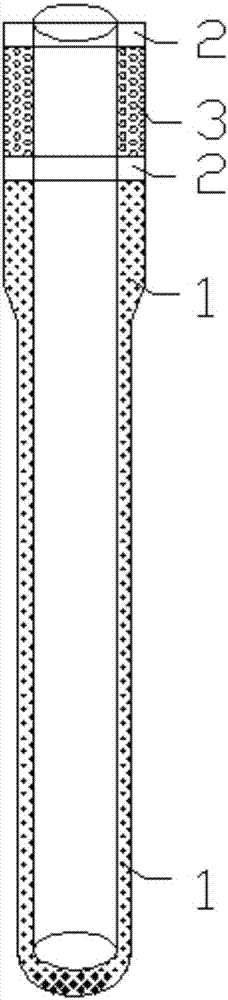

[0086] The plugging material includes an inorganic precipitation system and a polymer jelly system; the volume ratio of the inorganic precipitation system to the polymer jelly system is 1:2;

[0087] The inorganic precipitation system consists of 60 parts of Portland cement clinker, 10 parts of sulphoaluminate cement, 3 parts of bentonite, 0.2 parts of hydroxyethyl cellulose ether, 30 parts of polymer emulsion, plasticizer Agent 3, defoamer 2, thickener PRM-3000.5 parts, 8# quartz sand 20 parts;

[0088] The polymer jelly system is composed of a resin, an accelerator and a filler; the filler is composed of a first filler and a second filler; in parts by mass, 50-90 parts of a resin, 0.5-4 parts of an accelerator, and 0.5-4 parts of a first filler. 10-30 parts, 10-30 parts of the second filler.

Embodiment 2

[0090] The plugging material includes an inorganic precipitation system and a polymer jelly system; the volume ratio of the inorganic precipitation system to the polymer jelly system is 1:3.5;

[0091] The inorganic precipitation system consists of 80 parts of Portland cement clinker, 20 parts of sulphoaluminate cement, 6 parts of bentonite, 0.5 parts of hydroxyethyl cellulose ether, 40 parts of polymer emulsion, plasticizer 5 parts of agent, 3 parts of defoamer, 1 part of thickener PRM-300, 2025 parts of 8# quartz sand;

[0092] The polymer jelly system is composed of a resin, an accelerator and a filler; the filler is composed of a first filler and a second filler; in parts by mass, 50-90 parts of a resin, 0.5-4 parts of an accelerator, and 0.5-4 parts of a first filler. 10-30 parts, 10-30 parts of the second filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com