Laminated wood flooring and manufacturing method thereof

A technology for laminated wood flooring and manufacturing methods, which is applied in chemical instruments and methods, manufacturing tools, and wood layered products, etc., can solve the problems of easy-opening and detachment of adhesives, poor bonding strength of laminated wood flooring, etc., and achieve maintenance The effect of enhancing integrity and connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

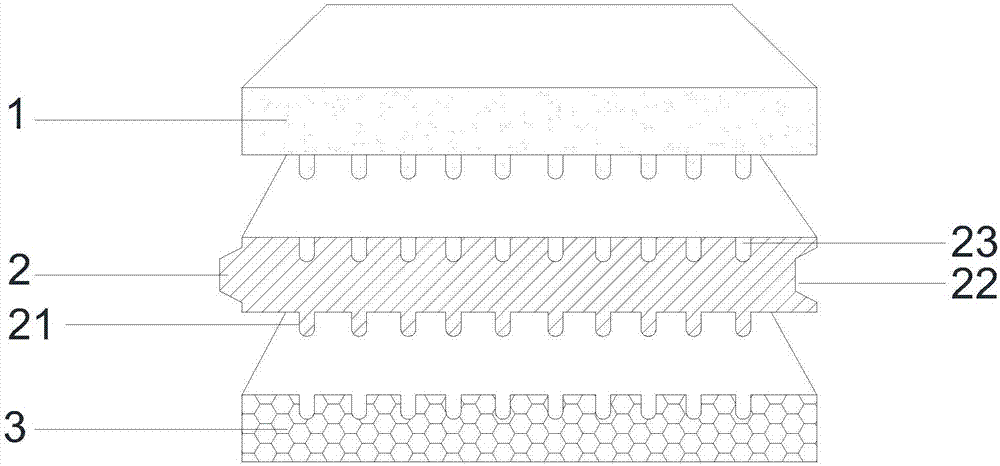

[0025] see Figure 1~2 , in the embodiment of the present invention, a kind of laminate flooring, comprises veneer layer 1, base material layer 2 and balance layer 3, and described veneer layer 1 and balance layer 3 are respectively positioned at the upper and lower ends of base material layer 2; Base material The upper end surfaces of layer 2 and balance layer 3 are provided with several grooves 23, and the front and rear end surfaces of said grooves 23 are inclined relative to the base material layer 2, and the lower end surfaces of the base material layer 2 and the veneer layer 1 are all arranged in line with the positions of the grooves 23 and The warp-shaped structure 21 whose shape corresponds to each other, so that each plate layer is fitted by the warp-shaped structure 21 and the groove 23, and the connection strength is greatly enhanced, and the groove 23 or the warped structure 21 is inclined, which can limit the horizontal direction of each plate layer. The relative...

Embodiment 2

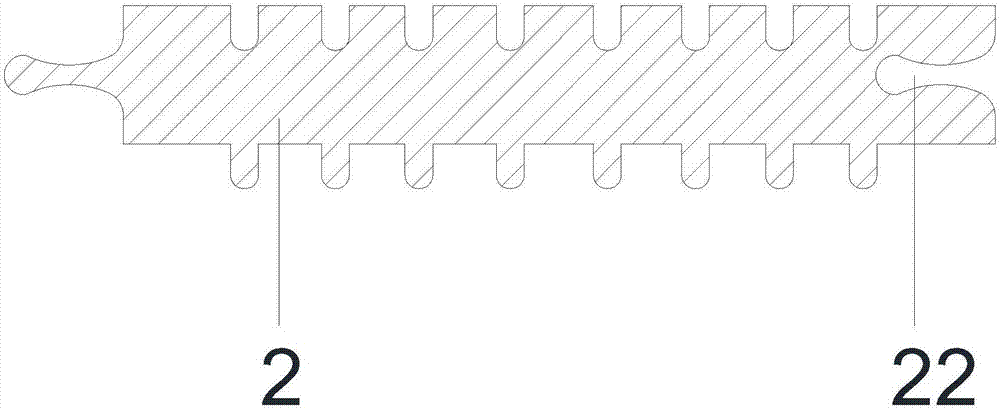

[0035] refer to image 3 The left and right sides of the substrate layer 2 are provided with drop-shaped slots 22, this structure can withstand a certain tensile force, and can enhance the bonding strength between different wooden floors.

[0036] The manufacturing method of a laminate flooring in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com