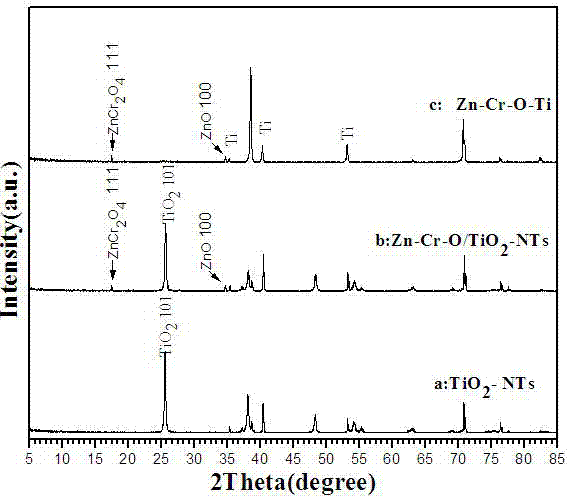

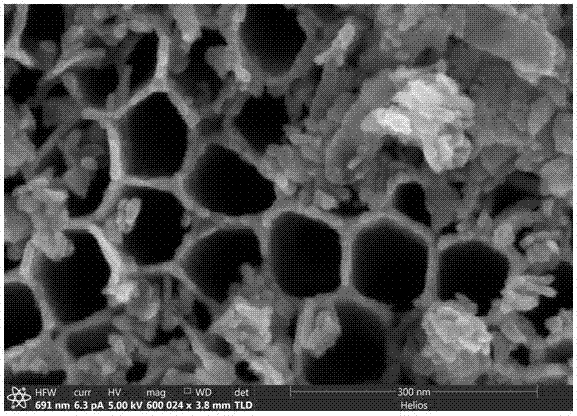

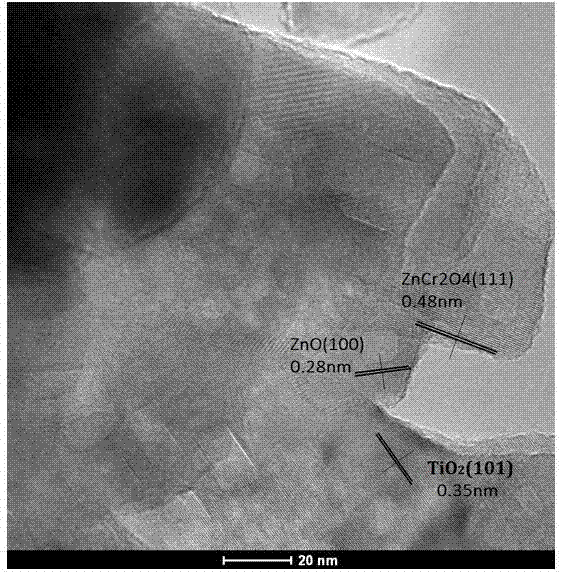

Preparation and application of Zn-Cr-O/TiO2 nanotube oxide with efficient photoelectric conversion and photocatalytic performance

A photoelectric conversion and photocatalysis technology, applied in electrodes, electrolytic coatings, electrolytic processes, etc., to achieve the effect of improving the activity of photocatalytic hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Polish the surface of the titanium sheet with 500-grit sandpaper, ultrasonically clean it with deionized water, acetone, and ethanol in turn, and dry it in the air as the anode in the battery;

[0028] (2) Dissolve 1,3-propanediol and NaF in ultrapure water and stir evenly as an electrolyte solution. The mass ratio of 1,3-propanediol, NaF and ultrapure water is 95:1:4. Fix the titanium plate treated in (1) as an anode on the battery holder, add electrolyte, connect the titanium plate to the positive pole of the power supply, connect the platinum plate to the negative pole of the power supply, control the voltage at 30 V, and oxidize for 5 hours;

[0029] (3) Wash the oxidized titanium sheet obtained in (2) with ethanol, air-dry it, and place it in a muffle furnace for temperature-programmed roasting in two stages. First, the temperature is raised to 400 °C at a heating rate of 2 °C / min, and the temperature is kept for 2 hours. Then use a heating rate of 4 °C / min to ...

Embodiment 2

[0035] (1) Same as step (1) in implementation example 1;

[0036] (2) Ethylene glycol, NH 4 HF 2 Dissolve in ultrapure water, stir evenly as electrolyte, in which ethylene glycol, NH 4 HF 2 The mass ratio to ultrapure water is 97.5:2.0:0.5. Fix the titanium plate processed in (1) as an anode on the battery holder, add electrolyte, connect the titanium plate to the positive pole of the power supply, and connect the platinum plate to the negative pole of the power supply. The control voltage is 40 V. Oxidation time is controlled at 4h;

[0037] (3) Wash the oxidized titanium sheet obtained in (2) with ethanol, air-dry it, and place it in a muffle furnace for temperature-programmed roasting in two stages. First, the temperature is raised to 400 °C at a heating rate of 2 °C / min, and the temperature is kept for 2 hours. Then use a heating rate of 5 °C / min to raise the temperature to 500 °C, keep it for 2 hours, and cool to room temperature to obtain TiO 2 -NTs;

[0038] (4)...

Embodiment 3

[0043] (1) Same as step (1) in the implementation example one;

[0044] (2) Dissolve 1,2-propanediol and NaF in ultrapure water and stir evenly as electrolyte, in which the mass ratio of 1,2-propanediol, NaF and ultrapure water is 96:3:1. Fix the titanium plate processed in (1) as an anode on the battery holder, add electrolyte, connect the titanium plate to the positive pole of the power supply, and connect the platinum plate to the negative pole of the power supply. The control voltage is 50 V. Oxidation time is controlled at 2h;

[0045] (3) Wash the oxidized titanium sheet obtained in (2) with ethanol, air-dry it, and place it in a muffle furnace for temperature-programmed roasting in two stages. First, the temperature is raised to 400 °C at a heating rate of 2 °C / min, and the temperature is kept for 2 hours. Then use a heating rate of 4 °C / min to raise the temperature to 800 °C, keep it for 1 h, and cool to room temperature to obtain TiO 2 -NTs;

[0046] (4) Weigh zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com