Anti-reddish slippery masterbatch and preparation method thereof

A masterbatch and smooth technology, which is applied in the field of modified masterbatch and its preparation, can solve the problems of not having anti-reddening function, and achieve anti-reddening effect and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

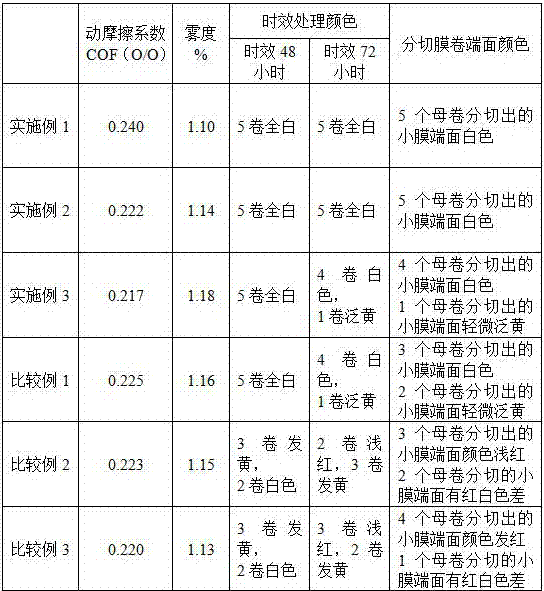

Embodiment 1~3 and comparative example 1~3

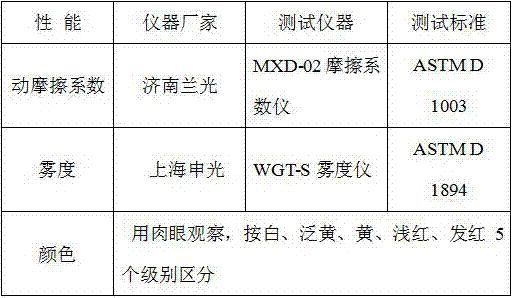

[0041] According to the formula shown in Table 1, the materials were weighed to prepare the anti-reddening smooth masterbatch.

[0042] Table 1: Components and contents of Examples 1 to 3 and Comparative Examples 1 to 3

[0043]

[0044] Behenic acid amide in Examples 1-3 was selected from Sichuan Tianyu Oleochemical Co., Ltd. 9822 type behenic acid amide, and the primary antioxidant 1076 and secondary antioxidant 626 were selected from the products of Suqian Liansheng Chemical Co., Ltd. The erucamide in Comparative Examples 1 to 3 was selected from the product of Croda in the United Kingdom, B215 was selected from the product of Tianjin Lianlong New Material Co., Ltd., and the primary antioxidant 1076 and secondary antioxidant 626 in the comparative example were the same as those in the embodiment.

[0045] The preparation of embodiment 1~3 and comparative example 1~3 is as follows:

[0046] S1: Weigh the primary and secondary antioxidants listed in Table 1 and mix them e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com