Multifunctional colorful three-dimensional effect tooling glass and processing method thereof

A multi-functional, glass-based technology, which is applied in the direction of producing decorative surface effects, special decorative structures, chemical instruments and methods, etc., can solve the problem of surface multicolor, poor visual effect of simulated pictures, inability to realize luminescence or heating, The color of the pattern is gray and dark, etc., to achieve the effect of realistic three-dimensional pattern, time-saving and labor-saving visual effects, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

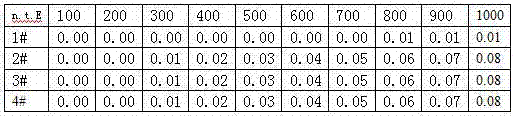

[0051] A method for processing multifunctional colored three-dimensional effect tooling glass, comprising the following steps:

[0052] A. Primary glass treatment

[0053] Apply a hydrochloric acid solution with a mass concentration of 3.6% on one side of the base glass to form an acidic medium coating;

[0054] B. Basic glass electrophoresis treatment

[0055] The base glass coated with acidic medium is energized for 5 minutes, and the energized voltage is 12V;

[0056] C. Wipe and clean the base glass

[0057] Wipe the base glass after electrification treatment, remove the acid medium coating, and dry the glass surface;

[0058] D. Film layer pattern processing

[0059] The pattern on the diaphragm layer is printed by a printer or drawn by hand;

[0060] E. Adhesive film layer bonding

[0061] One side of the base glass is coated with polypropylene adhesive, and the polypropylene adhesive is applied to form a 0.1mm adhesive layer, and the adhesive layer of the base gla...

Embodiment 2

[0065] A method for processing multifunctional colored three-dimensional effect tooling glass, comprising the following steps:

[0066] A. Primary glass treatment

[0067]Apply a hydrochloric acid solution with a mass concentration of 7.2% on one side of the base glass to form an acidic medium coating;

[0068] B. Basic glass electrophoresis treatment

[0069] The base glass coated with acidic medium is energized for 30 minutes, and the energized voltage is 24 V;

[0070] C. Wipe and clean the base glass

[0071] Wipe the base glass after electrification treatment, remove the acid medium coating, and dry the glass surface;

[0072] D. Film layer pattern processing

[0073] The pattern on the diaphragm layer is printed by a printer or drawn by hand;

[0074] E. Adhesive film layer bonding

[0075] One side of the base glass is coated with polypropylene adhesive, and the polypropylene adhesive is applied to form a 0.1mm adhesive layer, and the adhesive layer of the base gl...

Embodiment 3

[0079] A method for processing multifunctional colored three-dimensional effect tooling glass, characterized in that it comprises the following steps:

[0080] A. Primary glass treatment

[0081] Apply a hydrochloric acid solution with a mass concentration of 10% on one side of the base glass to form an acidic medium coating;

[0082] B. Basic glass electrophoresis treatment

[0083] The base glass coated with acidic medium is energized for 20 minutes, and the energized voltage is 15V;

[0084] C. Wipe and clean the base glass

[0085] Wipe the base glass after electrification treatment, remove the acid medium coating, and dry the glass surface;

[0086] D. Film layer pattern processing

[0087] The pattern on the diaphragm layer is printed by a printer or drawn by hand;

[0088] E. Adhesive film layer bonding

[0089] One side of the base glass is coated with polypropylene adhesive, and the polypropylene adhesive is applied to form a 0.1mm adhesive layer, and the adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com