Intelligent forging line system for industrial robot and application of industrial forging line system

An industrial robot and robot technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of abnormal working conditions without self-diagnosis and processing functions, insufficient ability to adapt to abnormal working conditions, and weak application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

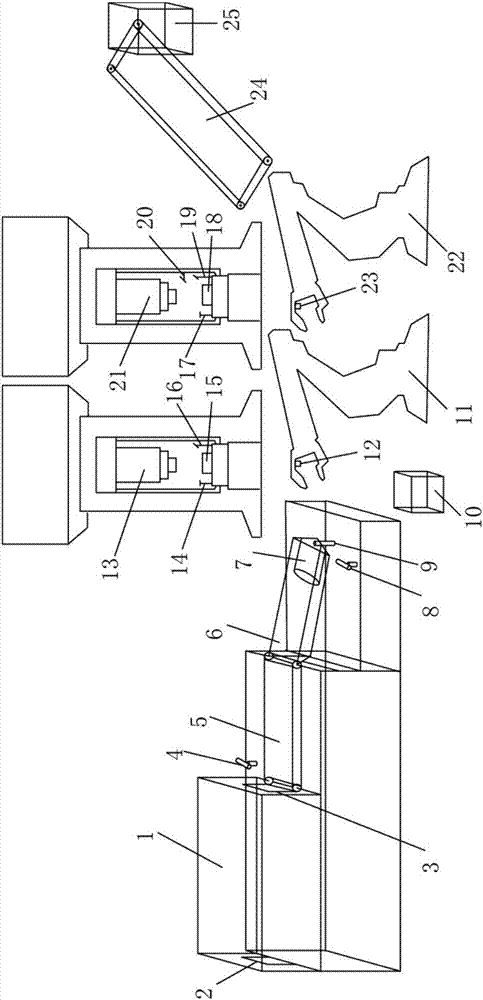

[0029] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

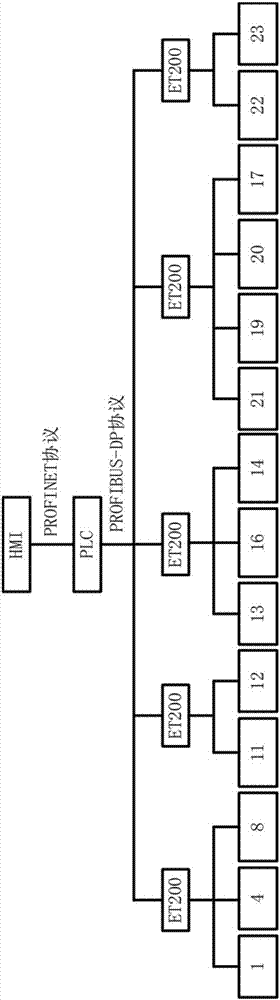

[0030] An industrial robot intelligent forging line system, including: an intermediate frequency heating furnace 1, an upsetting punch 13, a first robot 11 matching the upsetting punch and a press, a press 21, and a second robot 22 matching the press And the workpiece collection barrel 25; the intermediate frequency heating furnace 1 is used for heat treatment of the workpiece to be processed, the raw material is input from the feed port 2 of the intermediate frequency heating furnace 1, and the conveyor belt 5 is set at the discharge port 3 of the intermediate frequency heating furnace 1, and the intermediate frequency heating An infrared thermometer 4 is arranged near the exit of the furnace 1 and the infrared thermometer 4 faces the workpiece on the conveyor belt 5. The infrared thermometer 4 is used to detect the temperature of the workpiece at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com