Square power battery heat management structure

A power battery and thermal management technology, applied in the direction of secondary batteries, structural parts, battery pack components, etc., can solve the problems of battery pack failure, battery pack damage, battery pack fixed without heat dissipation and heating functions, etc., to achieve The effect of maintaining normal operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

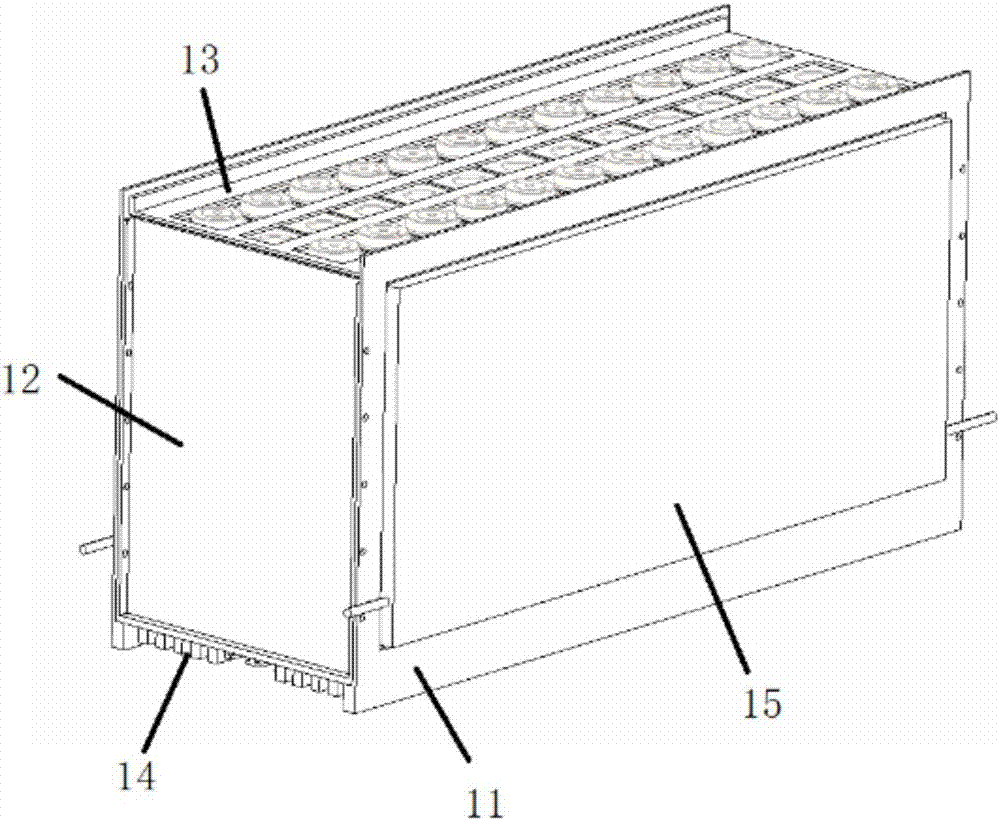

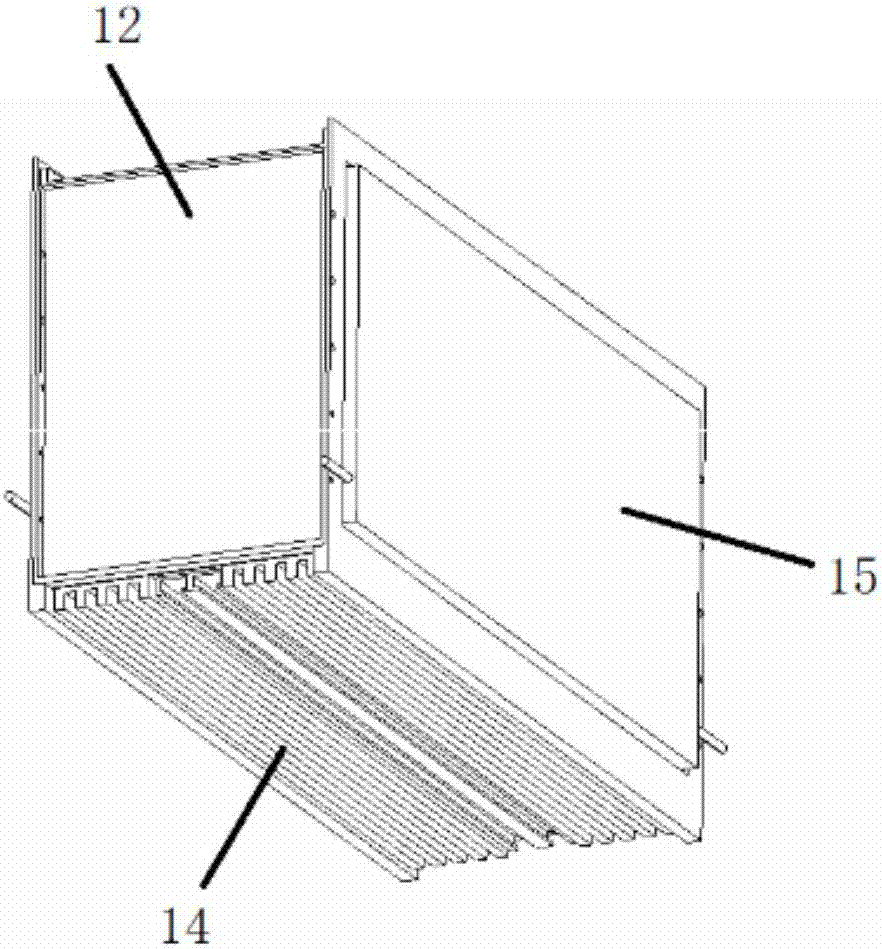

[0015] Such as Figure 1 to Figure 5 , the present invention discloses a thermal management structure of a square power battery, including a first side plate 11, a second side plate 12, a top plate 13, a PTC heater 14 and a heat dissipation unit 15, and the two first side plates 11 are arranged parallel to each other on the battery pack The two second side plates 12 are respectively fixedly connected to the left and right sides of the two first side plates 11 by screws, the top plate 13 is fixed to the upper ends of the two first side plates 11 by screws, and the PTC heater 14 is fixed by screws. At the lower ends of the two first side panels 11 , the cooling unit 15 is fixed on the sidewalls of the first side panels 11 .

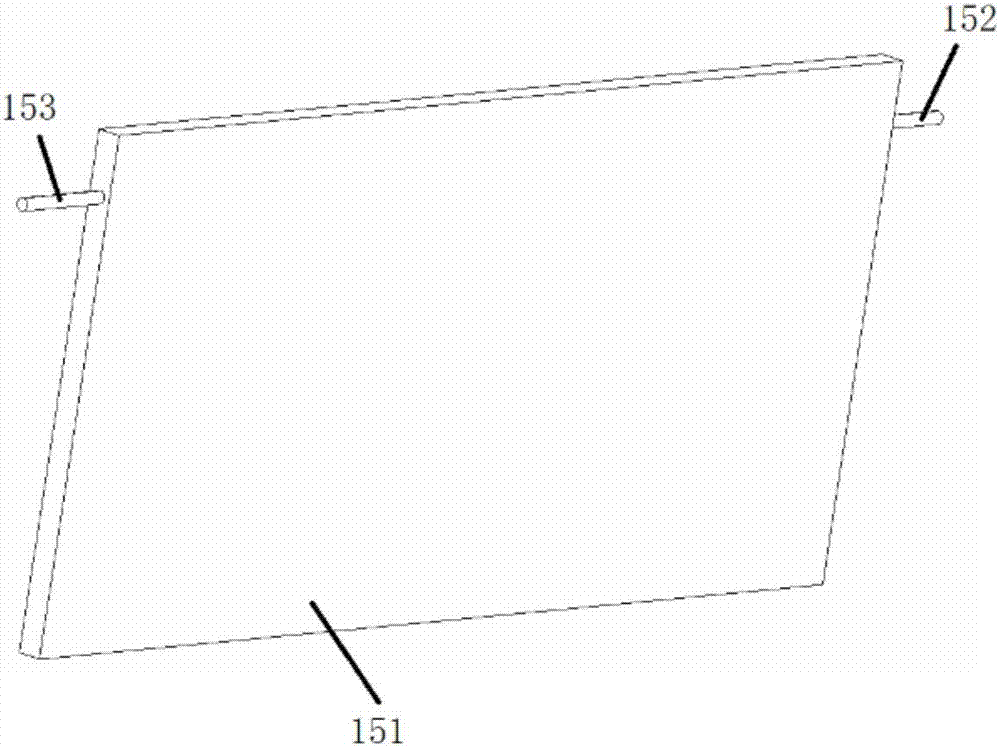

[0016] The heat dissipation unit 15 in the present invention includes a water cooling chamber 151 , a water inlet pipe 152 and a water outlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com