Butane catalytic oxidation reaction device

A catalytic oxidation and reaction device technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve the problems of cumbersome control of reactor liquid level, temperature and pressure, large butane recovery load, heat waste, etc., and achieve oxygen Low loss, high reaction efficiency, and improved flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

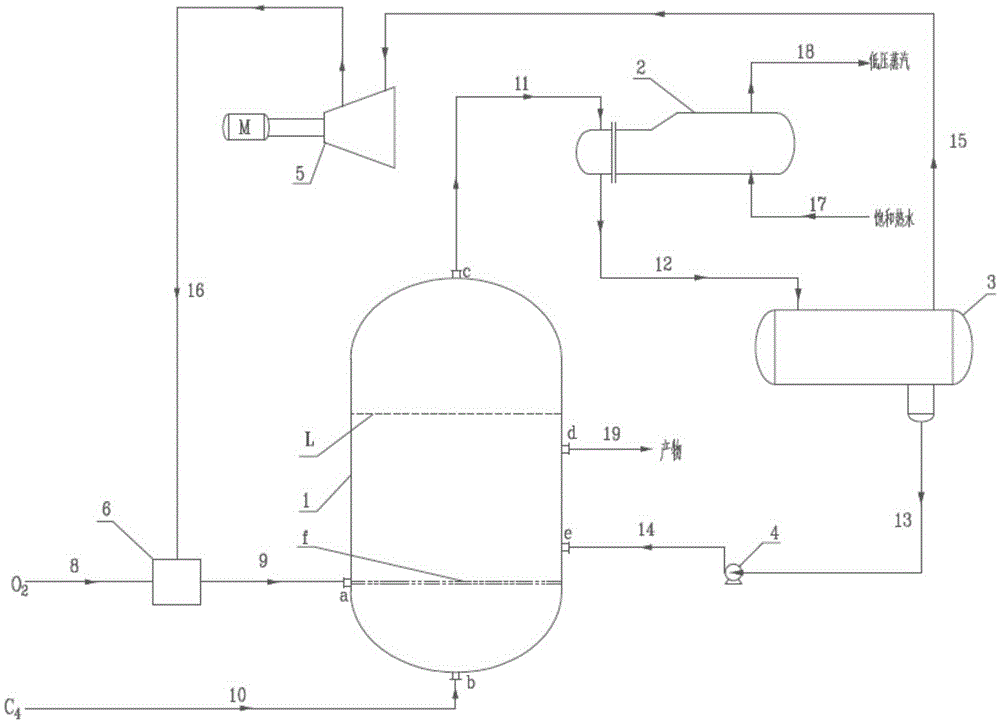

[0025] Such as figure 1 As shown, a butane catalytic oxidation reaction device includes a reactor cylinder 1, the ratio of the height of the cylinder 1 to the inner diameter is 1.5:1, and an oxygen inlet a is arranged on the lower side wall of the cylinder 1, which is connected with the inside of the reactor. The gas distributor f is connected, a butane raw material inlet b is set at the bottom of the cylinder 1, a gas phase material outlet c is set at the top of the cylinder 1, a reactant outlet d is set on the upper side wall of the cylinder 1, and a A circulating butane inlet e is arranged on the lower side wall.

[0026] The gas-phase material outlet c is connected to the waste heat recovery boiler 2 through the first pipeline 11, and the gas-liquid mixture after condensation and heat release enters the gas-liquid separation tank 3 through the second pipeline 12, and the condensate is circulated through the first condensate circulation pipeline 13 and butane The pump 4 an...

Embodiment 2

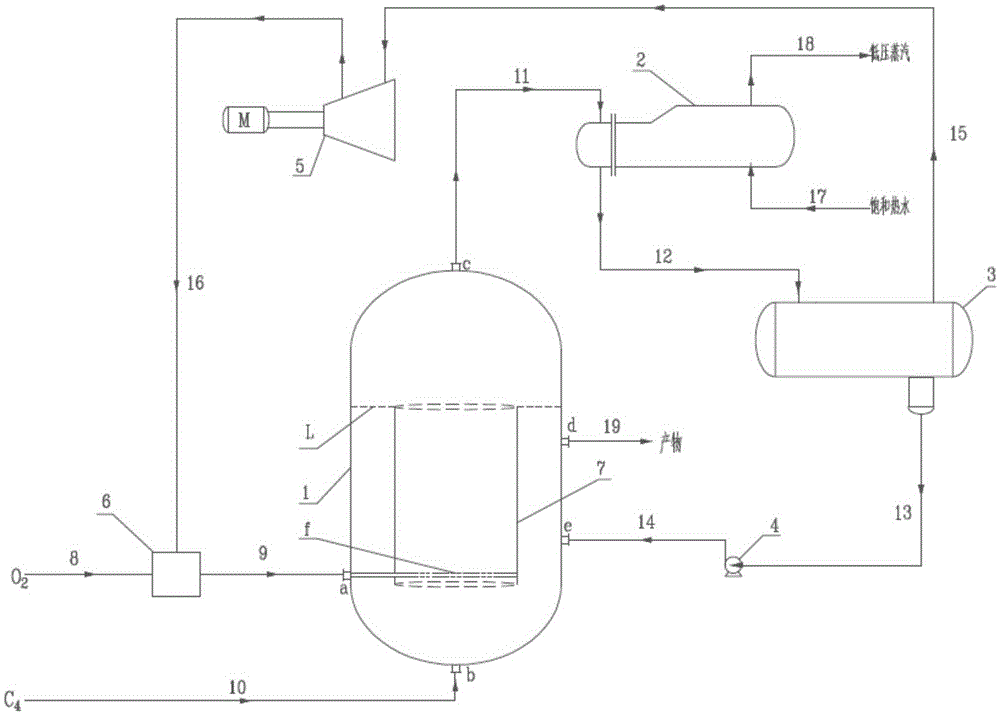

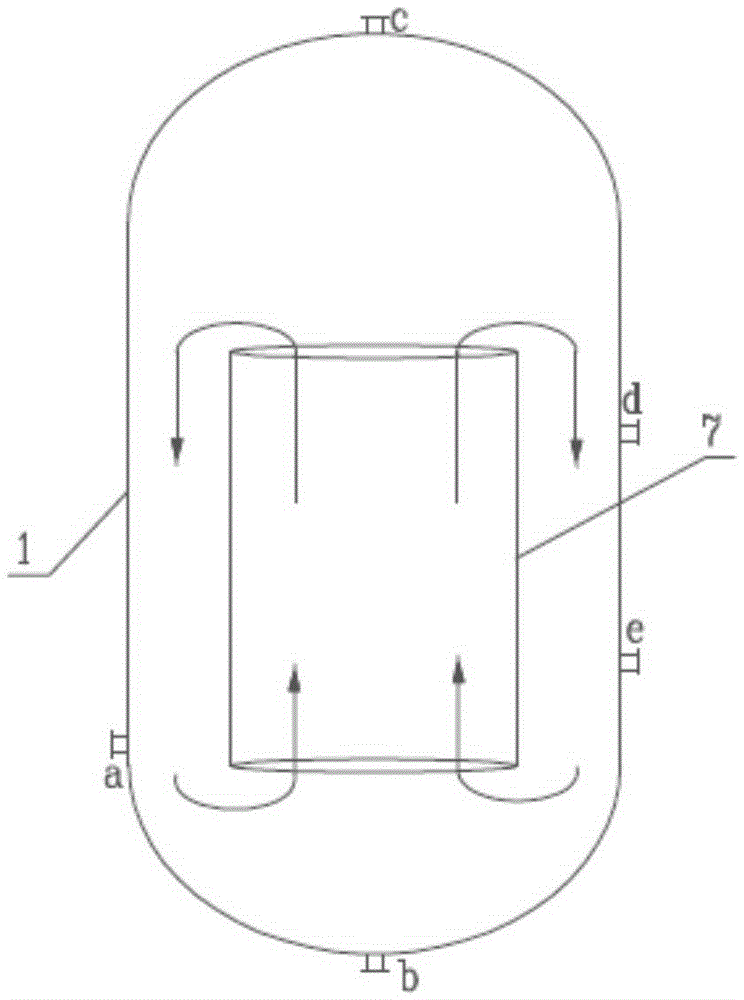

[0031] The composition of the butane catalytic oxidation reaction device is the same as that of Example 1, the difference is that a flow guiding cylinder 7 is added in the reactor cylinder body 1 to improve the flow effect in the reactor, so that the gas-liquid can be better mixed and the liquid phase can be increased. Medium gas holdup, the root of the diversion cylinder 7 is flush with the tangent line of the lower head of the reactor cylinder 1, the height of the diversion cylinder is 0.7 times the height between the upper and lower tangent lines of the reactor cylinder, and the diameter of the diversion cylinder 7 is The diameter ratio to the reactor cylinder 1 is 1:1.4; the composition and structure size of the rest remain unchanged.

[0032] In concrete work process, processing condition is the same as embodiment 1. The reaction product is analyzed by a gas chromatograph, the conversion rate of isobutane reaches 43.1%, and the selectivity of the product tert-butanol reac...

Embodiment 3

[0034] The composition of the butane catalytic oxidation reaction device is the same as that of Examples 1 and 2, except that the butane raw material is replaced by n-butane, and the composition and structure size of the rest of the reaction system remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com