High-temperature fume furnace of circulating fluidized bed and control method thereof

A circulating fluidized bed, high-temperature flue gas technology, applied in the field of flue gas furnaces, can solve the problems of uneven air distribution, low fluidization gas velocity, affecting combustion efficiency and flue gas quality, etc., so as to improve combustion efficiency and strengthen airflow. The effect of stirring and avoiding coking in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

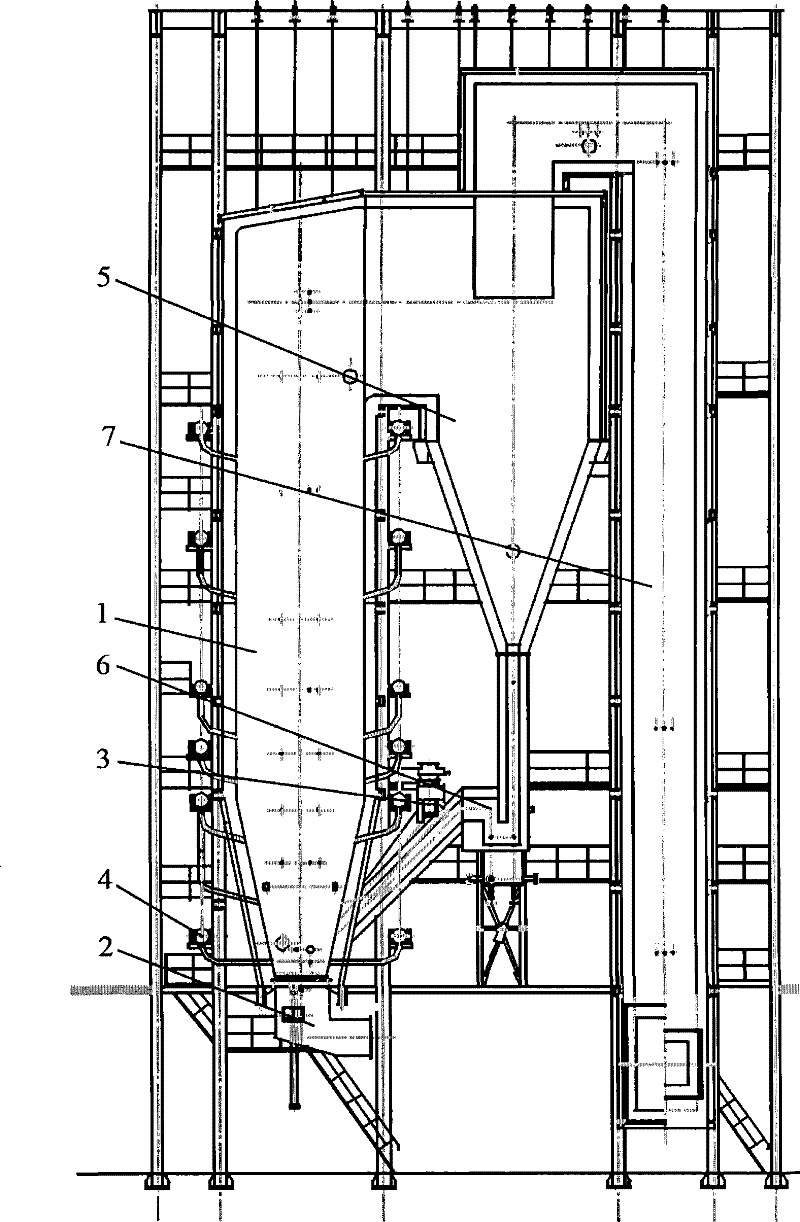

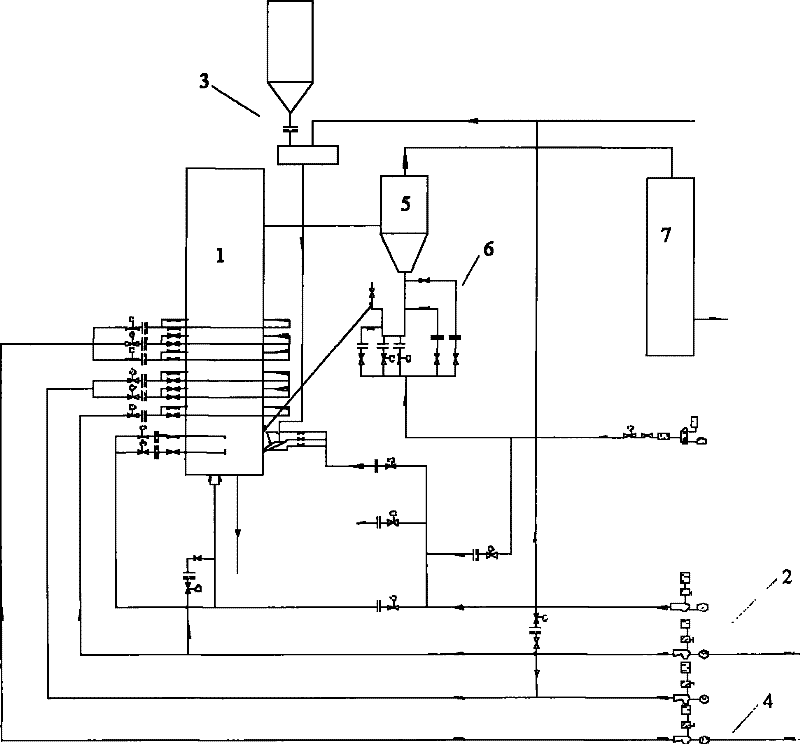

[0020] Such as figure 1 As shown, the circulating fluidized bed high-temperature flue gas furnace of the present invention includes a furnace 1, an air distribution device 2, a pneumatic coal sowing device 3, a secondary air and inert gas device 4, a cyclone separator 5, a feeding device 6 and a tail smoke Road 7. figure 2 It represents the control structure of the circulating fluidized bed high-temperature flue gas furnace of the present invention.

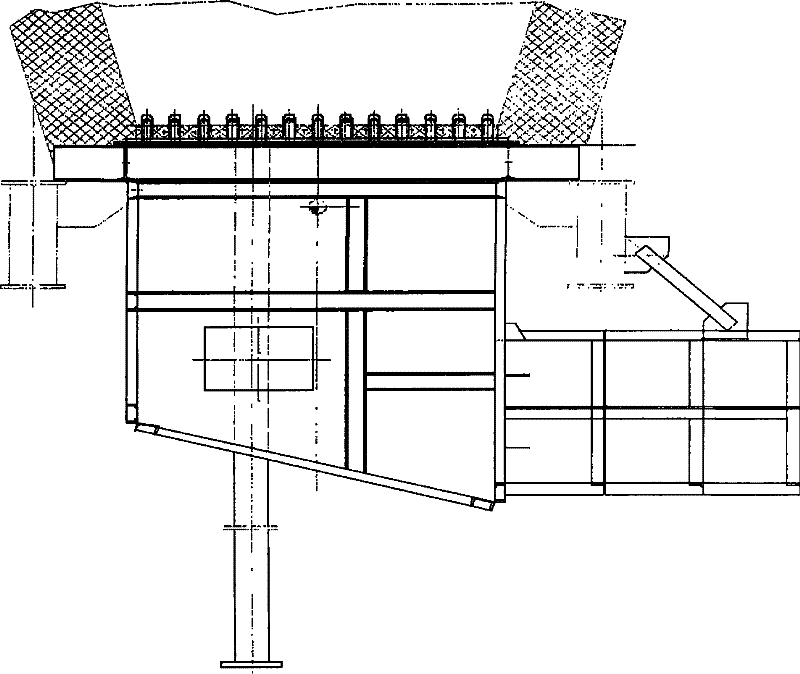

[0021] The air distribution device 2 includes components such as an air distribution plate, an air cap, and an air chamber. The air cap and the air distribution plate are installed in an equal-pressure air chamber, and the gas from a gas source (such as a fan) is introduced into the air chamber through the air cap arranged on the air distribution plate. , making coal fluidized combustion. The air outlet of the air distribution device 2 communicates with the furnace. The pneumatic coal sowing device 3 can be realized by a blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com