A gasification furnace device with a combined arrangement of water-cooled walls and refractory brick walls

A technology of gasification furnace and water-cooled wall, which is applied in gasification process, granular/powdered fuel gasification, and production of combustible gas. Achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

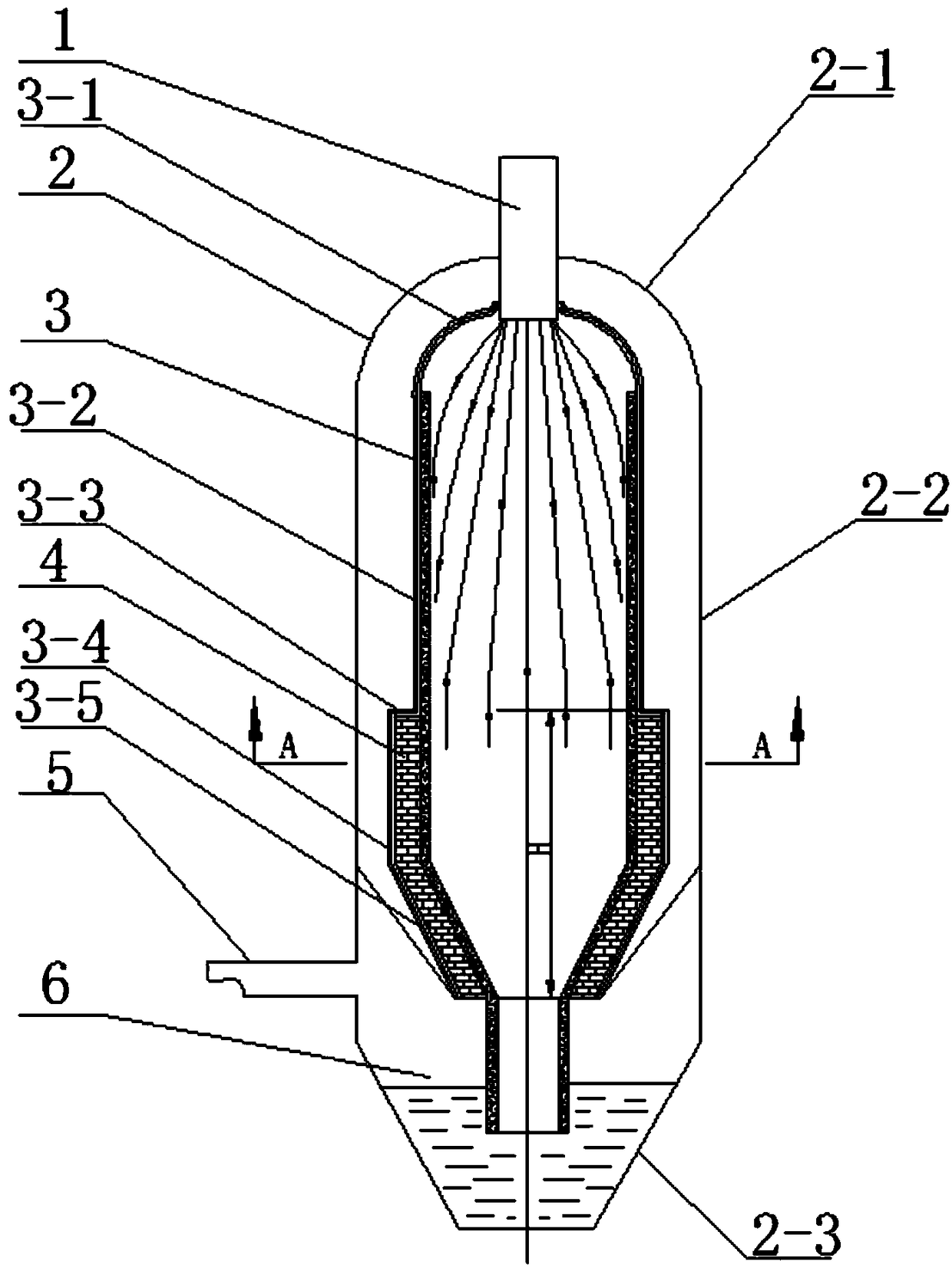

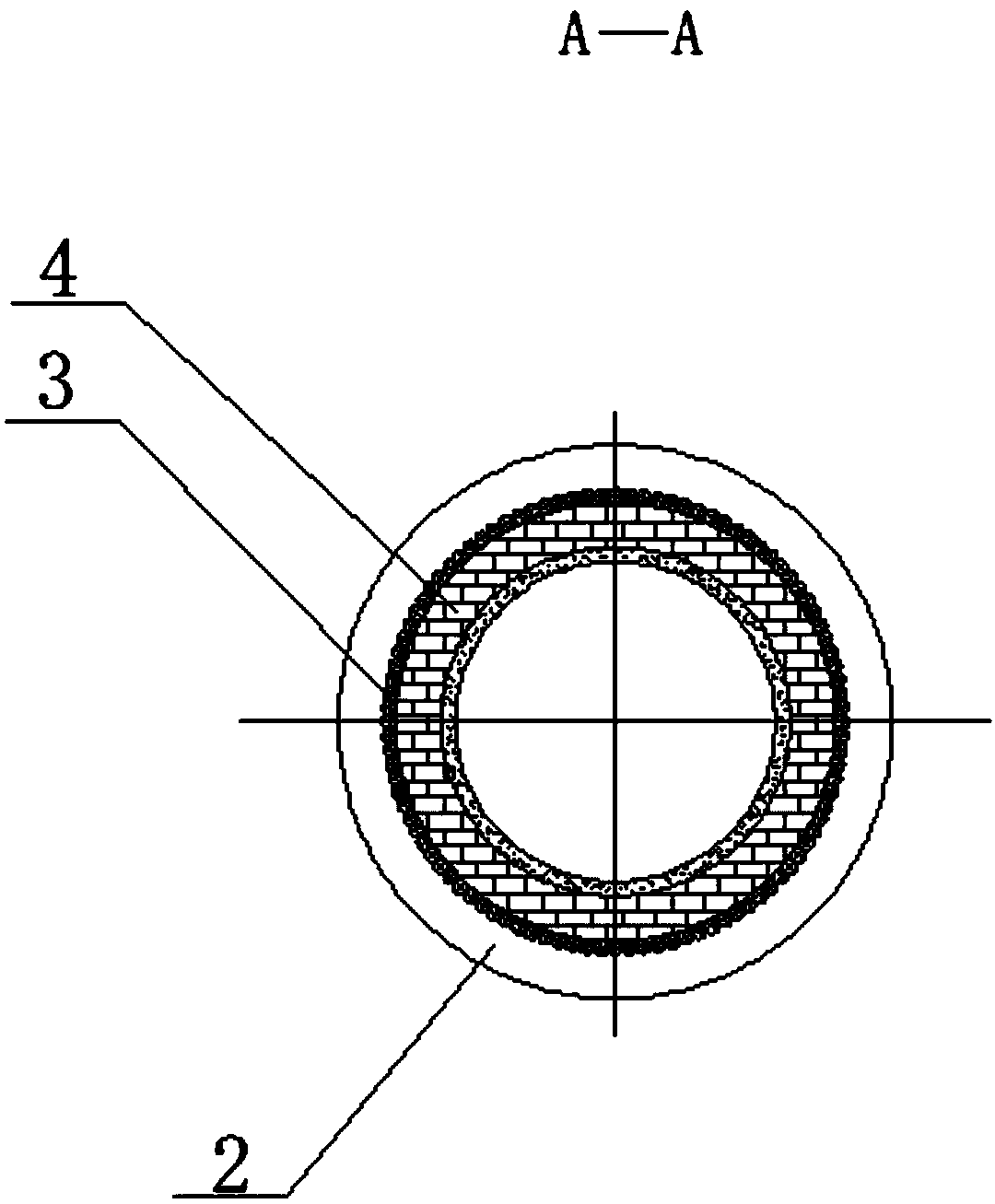

[0012] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a gasifier device in which a water-cooled wall and a refractory brick wall are arranged in combination in this embodiment, which includes a pulverized coal burner 1, a gasifier 2, a water-cooled wall 3, a syngas channel 5 and a slag pool 6 , the pulverized coal burner 1 is installed on the top of the gasifier 2, the water wall 3 is installed in the gasifier 2, the synthesis gas channel 5 is installed in the lower part of the gasifier 2, and the slag pool 6 is installed in the bottom of the gasifier 2 ; It is characterized in that: it also includes a refractory brick inner wall 4, and the water wall 3 includes an elbow section 3-1, a first vertical section 3-2, a horizontal section 3-3, a second vertical section 3-4 and an inclined section 3-5, the bent pipe section 3-1 is installed at the upper end of the first vertical section 3-2, and one end of the horizontal section 3-3 is in...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the gasifier 2 of this embodiment includes a hemisphere 2-1, a cylinder 2-2 and a cone 2-3, and the hemisphere 2-1, cylinder 2-2 and cone 2-3 consist of Connect from top to bottom. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 Describe this embodiment, the pulverized coal burner 1 of this embodiment is a cylindrical burner, and the axis of the pulverized coal burner 1 coincides with the axis of the cylinder 2-2 of the gasifier 2 . Such setting facilitates the uniform distribution of coal powder and gasification agent sprayed into the furnace through the burner in the furnace space, so that the heat load of the furnace space is uniform. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0015] Specific implementation mode four: combination figure 1 The present embodiment is described. The water-cooled wall 3 of the present embodiment is composed of a plurality of circular tubes arranged sequentially in an annular manner. With such an arrangement, the other composition and connection relations of the furnace space that facilitates the combustion and gasification reaction of pulverized coal are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com