Novel energy-saving prefabricated fabricated circular-cone unit combined body roof structure

A technology of prefabricated assembly and assembly, applied in the direction of roofs, building components, building structures, etc., can solve the problems of anti-moisture and corrosion, poor anti-moth-eaten performance, difficult to meet the stress requirements of large-span structures, and low wood strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described.

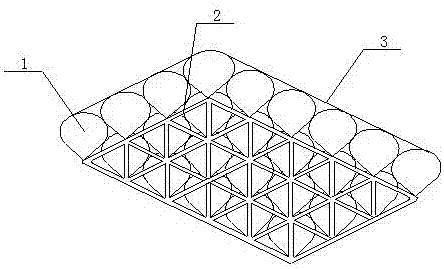

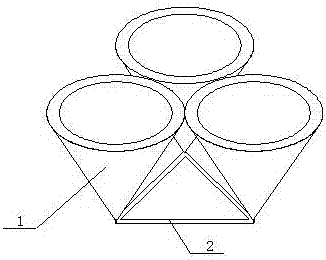

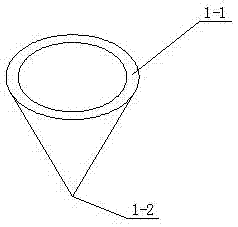

[0018] see Figure 1-3 As shown, the technical solution adopted in this embodiment is: it comprises several hollow cone units 1 and connecting rods 2; each hollow cone unit 1 is filled with an inert gas, and the bottom surface circle of the hollow cone unit 1- 1 is provided with a transparent sealing film cover 3; the bottom circle 1-1 of the hollow cone unit faces upward, and the apex 1-2 faces downward; the bottom circle 1-1 of the adjacent hollow cone unit is tangent and merged, The apex 1-2 of the hollow cone unit is fused with the connecting rod 2 and connected in pairs through the connecting rod 2 to form a large-span roof structure;

[0019] Preferably, the hollow cone unit 1 is a headless hollow cone made of transparent high-strength polymer composite material; the transparent high-strength polymer composite material can be polycarbonate or polyimide material;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com