Production process for producing case board paper printing layer by waste paper

A production process and printing layer technology, applied in the field of papermaking, can solve the problems of low quality, rough paper, poor use effect, etc., and achieve the effect of high quality paper, water resistance life, and good crosslinking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

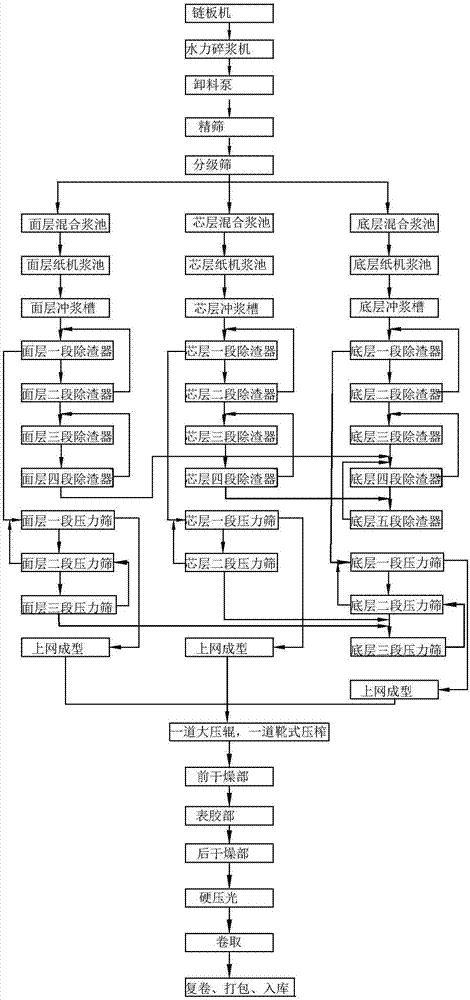

[0046] A kind of production technology that adopts waste paper to produce cardboard paper printing layer, refer to figure 1 shown, including the following steps,

[0047] Step 1: Transport the raw waste paper to the hydraulic pulper through the chain plate machine for disintegration, discharge the coarse pulp, slag, and plastic, and transport the pulp to the high-consistency slag remover through the discharge pump to remove the slag. After the good pulp is collected After fine sieving and grading sieve classification, short fibers, medium fibers and long fibers are formed;

[0048] Step 2: The cardboard printing layer includes a surface layer, a core layer and a bottom layer, wherein the surface layer includes 45% long fibers, 25% short fibers, and 25% long fibers in parts by weight, and the core layer includes a mass fraction of 35% % short fibers, 32% medium fibers, 33% long fibers, the bottom layer includes 50% short fibers, 25% medium fibers, and 25% long fibers;

[0049...

Embodiment 2

[0063] A kind of production technology that adopts waste paper to produce the printing layer of cardboard paper, the difference between embodiment 2 and embodiment 1 is that the fiber content of cardboard surface layer, core layer and bottom layer in step 2, wherein the surface layer comprises the parts by weight of 45% long fibers, 27% short fibers, 28% long fibers, the core layer includes 34% short fibers, 34% medium fibers, and 32% long fibers, and the bottom layer includes 45% mass fraction The short fiber of 28%, the medium fiber of 27%, the long fiber of 27%, all the other are consistent with embodiment 1.

Embodiment 3

[0065] A kind of production technology that adopts waste paper to produce cardboard printing layer, the difference between embodiment 3 and embodiment 1 is that the fiber content of cardboard surface layer, core layer and bottom layer in step 2, wherein surface layer comprises the parts by weight of 44% long fibers, 28% short fibers, 28% long fibers, the core layer includes 33% short fibers, 33% medium fibers, and 34% long fibers, and the bottom layer includes 50% mass fraction The short fiber of 29%, the medium fiber of 21%, the long fiber of 21%, all the other are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com