Anti-fog coating material and preparation method thereof

A technology of anti-fog coating and alkyd resin, applied in the direction of polyester coating, epoxy resin coating, polyurea/polyurethane coating, etc. Coating anti-fog reduction and other problems, to achieve the effect of enhancing practicability and safety, improving scratch resistance and adhesion, and good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

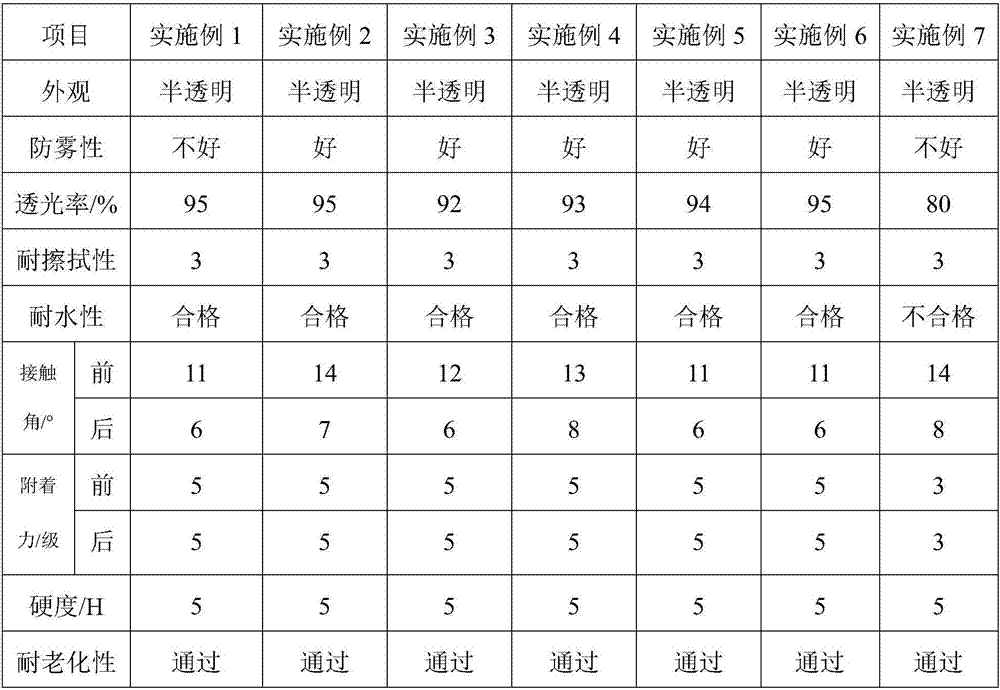

Examples

preparation example Construction

[0032] The following is the preparation method of each example anti-fog coating:

[0033] (1) Add acrylic resin, alkyd resin and epoxy resin to the reaction kettle, heat and stir for 3-5min, heat to 50-55°C, the speed of the stirring device during stirring is 800r / min, add defoamer and coupler For the coupling agent, keep the temperature and rotation speed constant, continue heating and stirring for 2-4 minutes, then add inorganic nanoparticles and surfactants, keep the temperature and rotation speed constant, continue heating and stirring for 3-5 minutes;

[0034] (2) Stop heating, adjust the rotating speed of the stirring device to 500r / min, wait for the temperature in the reactor to drop to 40°C, add fatty acid sodium and binary block copolymer containing propionamide and hydroxyethyl ester in the reactor , then adjust the rotating speed of the stirring device to 600r / min, and stir for 3-4min;

[0035] (3) When the temperature drops to 30°C, add essence into the reaction k...

Embodiment 1

[0036] Embodiment 1: (comparative example)

[0037] An anti-fog coating, the parts by mass of each component are: 10 parts of hydroxyethyl acrylate, 10 parts of butyl acrylate, 10 parts of dry short oil alkyd resin, 15 parts of acrylic acid modified alkyd resin, glycidol 10 parts of ester epoxy resin, 3 parts of sodium fatty acid, 10 parts of binary block copolymer containing propionamide and hydroxyethyl ester, 5 parts of sodium lauryl sulfate, 5 parts of polyammonium methacrylate, graphite-like phase Carbon nitride 4 parts, nano ZrO 2 4 parts, 0.3 parts of polydimethylsiloxane, 0.5 parts of silane coupling agent, 0.5 parts of γ-glycidyl ether propyl trimethoxysilane, 1 part of essence.

[0038] Spray the paint on the glass, adjust the indoor and outdoor temperature difference to 15°C, observe after 24 hours: there are obvious fog traces on the glass, there is a whitening phenomenon, and the water droplets on the surface are discontinuous, and the anti-fog effect is not good....

Embodiment 2

[0040] An anti-fog coating, the parts by mass of each component are: 10 parts of hydroxyethyl acrylate, 10 parts of butyl acrylate, 10 parts of dry short oil alkyd resin, 15 parts of acrylic acid modified alkyd resin, glycidol 10 parts of ester epoxy resin, 5 parts of sodium fatty acid, 10 parts of binary block copolymer containing propionamide and hydroxyethyl ester, 5 parts of sodium lauryl sulfate, 5 parts of polyammonium methacrylate, graphite-like phase Carbon nitride 4 parts, nano ZrO 2 4 parts, 0.3 parts of polydimethylsiloxane, 0.5 parts of silane coupling agent, 0.5 parts of γ-glycidyl ether propyl trimethoxysilane, 1 part of essence.

[0041] Spray the paint on the glass, adjust the indoor and outdoor temperature difference to 15°C, and observe after 24 hours: there is no obvious trace of fog on the glass, no whitening phenomenon, and the anti-fog effect is good. After adding a strong light source outdoors, the eyes can not feel strong The light does not affect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com