Method for recycling damaged cement concrete pavement to form road base

A technology of cement concrete and road base, applied in the direction of cement production, etc., to achieve the effect of reducing use and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The concrete preparation method of cementitious material comprises the steps:

[0022] (21) Dissolve NaOH solid particles in purified water, stir until completely dissolved, and let stand to cool to room temperature;

[0023] (22) add water glass solution in the NaOH solution of cooling, stir;

[0024] (23) Slowly add the solution obtained in step (22) into the mixture of waste concrete powder and fly ash, and fully stir until uniform to ensure that silicon, aluminum, and calcium are fully dissolved.

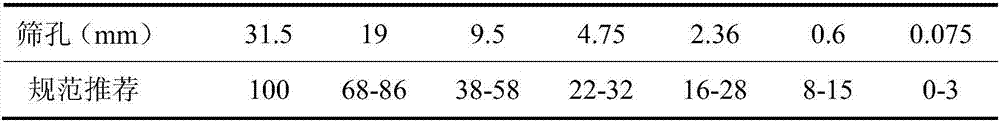

[0025] The gradation of recycled aggregates is specifically: the content of recycled aggregates with a particle size less than 31.5mm is 100%; the content with a particle size between 19-31.5mm is 14%-32%; the particle size is between 9.5-19mm 28%-30%; the particle size between 4.75-9.5mm is 16%-26%; the particle size is 4%-6% between 2.36-4.75mm; the particle size is 0.6-2.36 The content between mm is 8%-13%; the content of particle size between 0.075-0.6mm is 8%-12%; ...

Embodiment 1

[0051]Using the waste concrete produced by a damaged cement concrete pavement as raw materials, coarse and fine aggregates and waste concrete powder are obtained by screening, and the waste concrete powder is ground and screened to obtain the part with a particle size of less than 0.075mm. Waste concrete powder and fly ash are used as main raw materials, sodium hydroxide solution and water glass are used as alkali activators to prepare geopolymer cementitious materials, and the specific mixing ratio of each component is waste concrete powder: fly ash=70 : 30, NaOH solution concentration=18mol / L, water glass modulus is 1.5.

[0052] According to the unconfined compressive strength, the 7-day unconfined compressive strength of the geopolymer cementitious material is as high as 41.5Mpa.

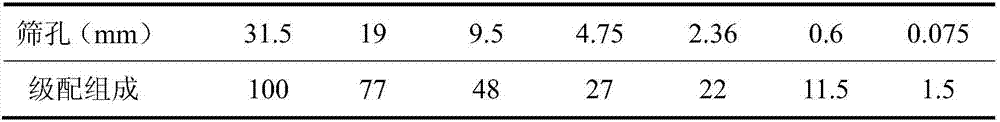

[0053] Table 2 Semi-rigid base aggregate gradation

[0054]

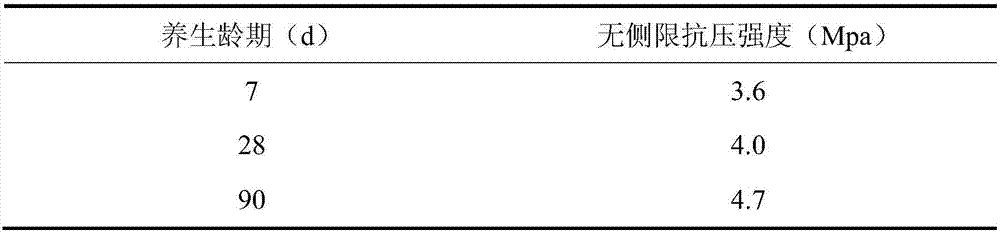

[0055] The amount of geopolymer cementitious material in the semi-rigid base material is 5.5%, and the samples are tested for un...

Embodiment 2

[0069] Using the waste concrete produced by a damaged cement concrete pavement as raw materials, coarse and fine aggregates and waste concrete powder are obtained by screening, and the waste concrete powder is ground and screened to obtain the part with a particle size of less than 0.075mm. Using waste concrete powder and fly ash as main raw materials, sodium hydroxide solution and water glass as alkali activator to prepare geopolymer cementitious material, the mixing ratio is waste concrete powder: fly ash = 60: 40, NaOH Solution concentration=18mol / L, water glass modulus is taken as 2.0.

[0070] According to the unconfined compressive strength, the 7-day unconfined compressive strength of the geopolymer cementitious material is as high as 30.2Mpa.

[0071] Table 7 Semi-rigid base aggregate gradation

[0072]

[0073] The amount of geopolymer cementitious material in the semi-rigid base material is 5.5%, and the samples are tested for unconfined compressive strength, spl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com