Robot grabbing part applied to engine assembling production line

A technology for assembly production lines and robot arms, which is applied in the directions of manipulators, chucks, manufacturing tools, etc. It can solve the problems of inconvenient replacement and installation, fewer types of workpieces, and insufficient intelligence, and achieve the effect of easy replacement and installation and various clamping methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

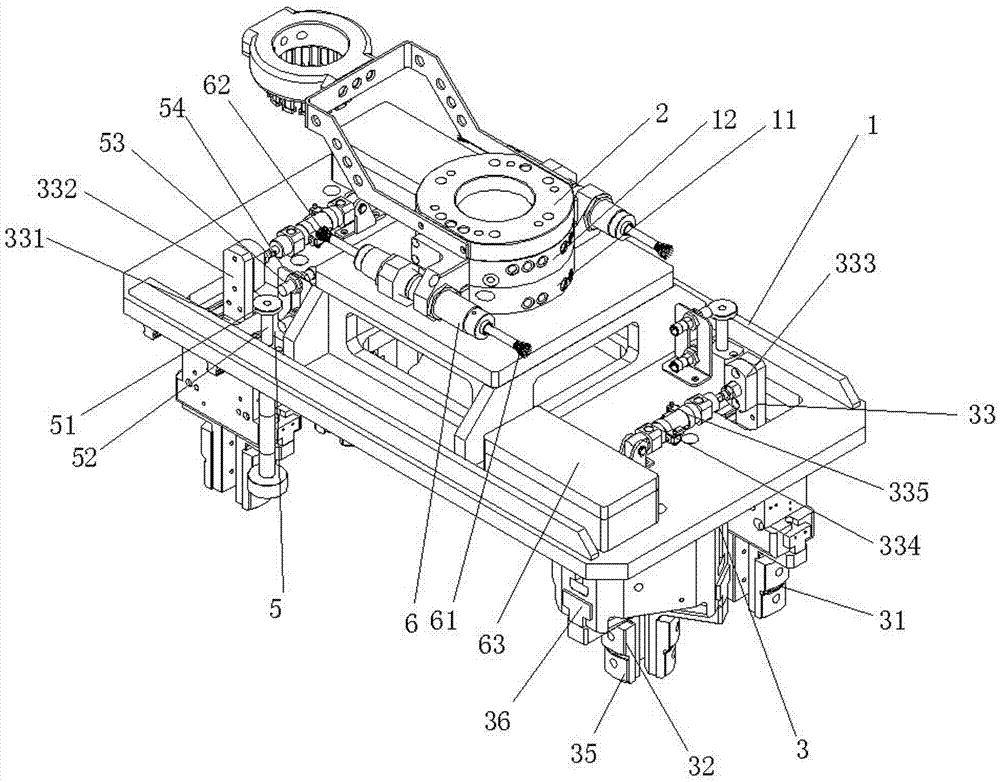

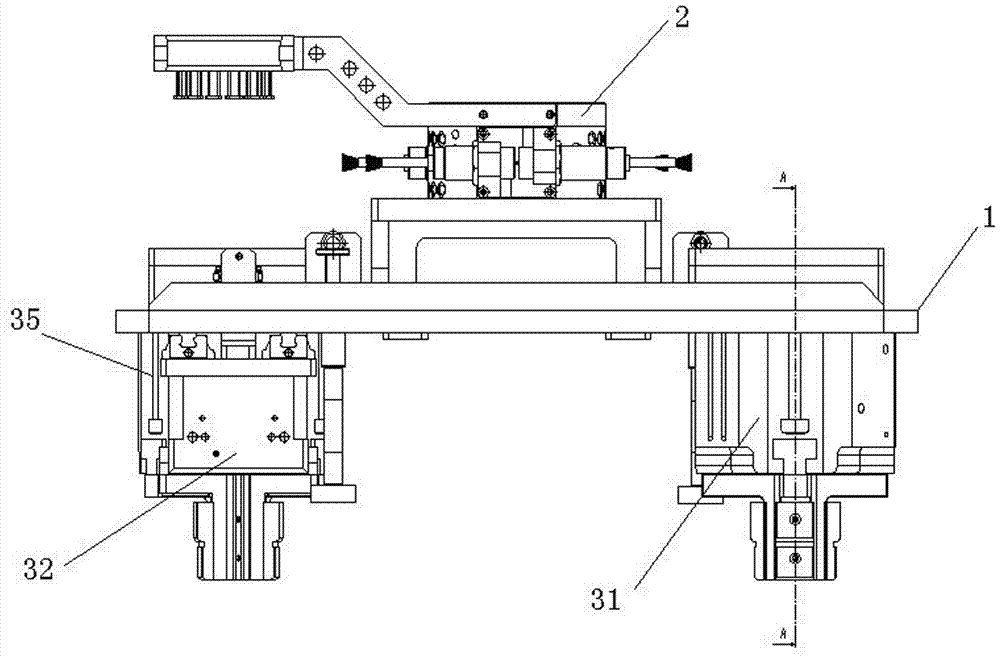

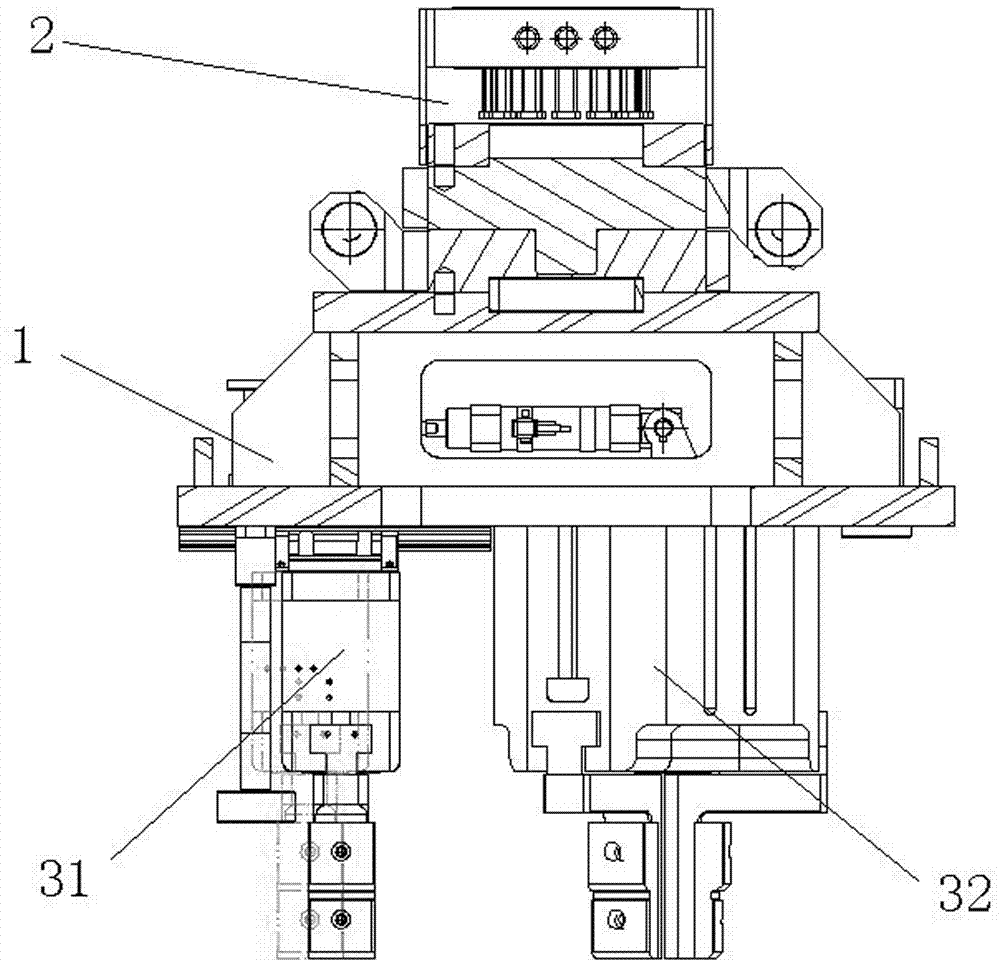

[0031] The invention provides a transmission mechanism 33 An embodiment of the transmission mechanism 33 Includes activity board 331 , movable board connector 332 , floating block 333 and variable pitch cylinder 334 , both hands 31 fixed on movable plate 331 on the flap 331 Via flap connectors 332 with floating block 333 connection, floating block 333 through the cylinder liner 335 with variable pitch cylinder 334 Connect; need to move both grippers 31 , the pneumatic mechanism 4 Control variable pitch cylinder334 , push the floating block 333 move so that the flap connector 332 Mobile, connected to movable plate connectors 332 lower movable panel 331 Simultaneously drive both hands to grasp 31 , so as to stabilize and quickly make the two-handed grip 31 Get some exercise.

[0032] further, hand Grab the body 1 There is also an induction mechanism for sensing and positioning the workpiece 5 and wirele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com