Fixture for L-shaped thin-wall annular part and machining method

The invention relates to a ring-shaped part and processing method technology, which is applied to the fixture and processing field of L-shaped thin-walled ring-shaped parts, and can solve the problems affecting the uniformity of workpiece wall thickness processing, workpiece size out of tolerance, deformation of L-shaped thin-walled ring-shaped parts, etc. Achieve the effect of reducing workpiece transfer time, fast positioning and alignment, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

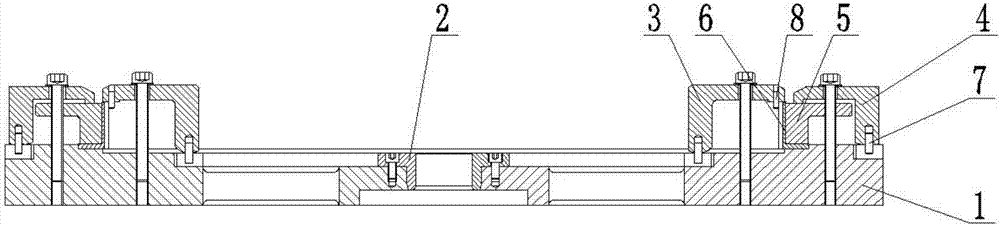

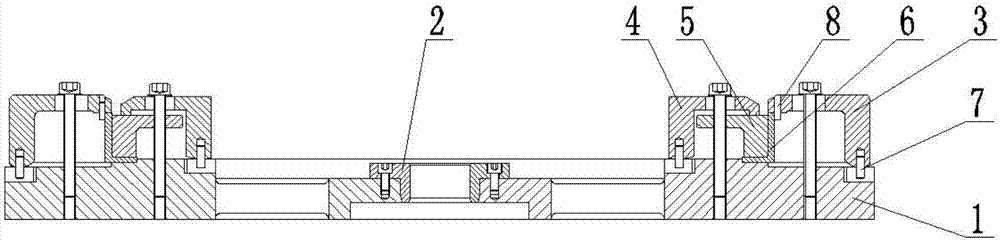

[0025] The invention provides a processing method and a fixture for an L-shaped thin-walled annular part, such as figure 1 , figure 2 As shown, the fixture includes a clamp body 1, a positioning sleeve 2, a pressure plate A3, a pressure plate B4, and a compression sleeve 5. The positioning sleeve 2 is connected to the center of the clamp body 1, and the positioning sleeve 2 is connected to the spindle of the machine tool. The pressure plate A3 and pressure plate B4 are used respectively. The pin 7 is positioned with the end face of the clamp body 1, and the pressure plate A3 and the pressure plate B4 are respectively connected with the clamp body 1 by bolts, and a compression sleeve 5 is also provided at the lower end of the pressure plate B4. Using the technical solution pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com