A secondary cooling spray equipment for high-speed production of billet continuous casting machine

A technology of billet continuous casting and spraying equipment, which is applied in the field of metallurgy, can solve problems such as internal cracks and square removal, and achieve the effects of reducing investment costs, stabilizing high-speed production, and increasing annual production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

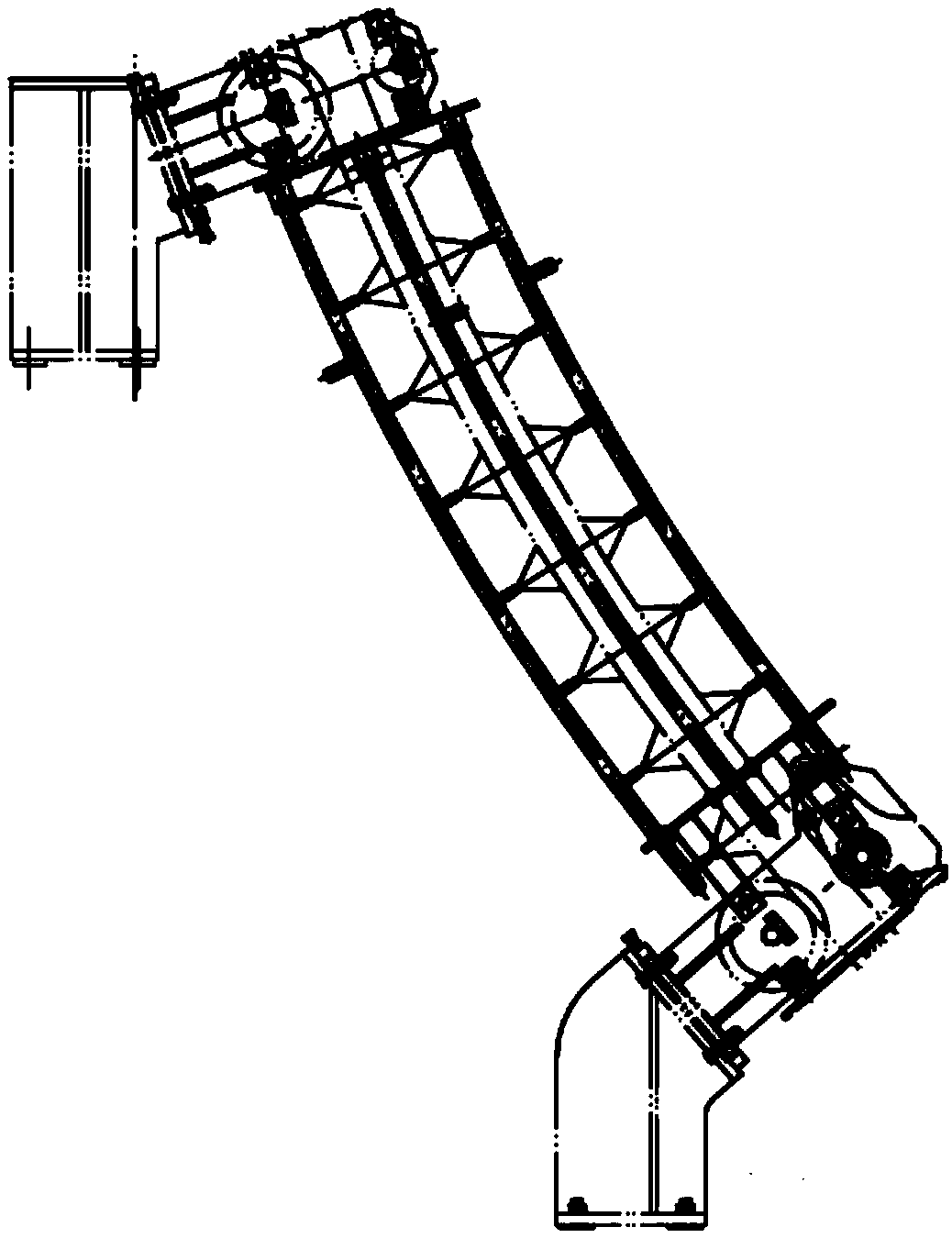

Image

Examples

Embodiment 1

[0038] In addition to the foot roller, 6 spray racks are used, of which 2 spray racks are a cooling zone, controlled by a water valve, and each spray rack has a spray pipe on the left, right, and inside, with a length of 1.6m. The spray pipe is provided with 4 rectangular aerosol nozzles, each of which has a spray angle of 90° in the wide direction and a spray angle of 35° in the narrow direction, and a water pressure of 1.2MPa. Two adjacent aerosol nozzles The distance between them is 460mm, the height of the first two spray rack air mist nozzles from the surface of the slab is 250mm, the height of the middle two is 240mm, and the height of the last two is 220mm. Achieved a casting speed of 3.0m / min for billet 72A steel with a cross-section of 150*150mm, 3.0-3.5m / min for medium-high carbon steel, and 4.0m / min for ordinary carbon steel, and the production of billets without intermediate cracks .

Embodiment 2

[0040] In addition to the foot roller, 6 spray racks are used, of which 2 spray racks are a cooling zone, which is controlled by a water valve and named as zone 2, zone 3, and zone 4 respectively; A spray pipe with a length of 1.7m. Four rectangular aerosol nozzles are arranged on the upper and lower (i.e. inner and outer arc) spray pipes. The angle is 35°, the water pressure is 1.2MPa, and the distance between two adjacent aerosol nozzles is 460mm. The left and right spray pipes are provided with 5 rectangular aerosol nozzles, each of which has a spray angle of 90° in the wide direction, a spray angle of 35° in the narrow direction, and a water pressure of 1.2MPa. The distance between the mist nozzles is 380mm, the height of the first air mist nozzle at the top from the surface of the continuous casting slab is 260mm, and the height of the air mist nozzles along the casting direction from the surface of the continuous casting slab is gradually shortened by 4mm. The billet GC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com