Powdery material for cable-hole fireproof sealing

A fire blocking and cable hole technology, applied in cable entry sealing device, cable accessories, cable installation and other directions, can solve the problems of hardening, unusability, short shelf life of paste and mud, etc., and achieve long shelf life, low manufacturing cost, fire resistance long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

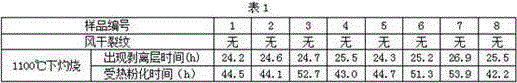

Embodiment 1

[0022] (1) Raw material preparation: 75 parts of magnesia powder, 8 parts of dry clay powder, SiO 2 1 part of micro powder, 6 parts of sodium hexametaphosphate, 4 parts of quicklime powder, 3 parts of refractory fiber.

[0023] The magnesia powder passes through the 200-mesh sieve, and the dry clay powder passes through the 380-mesh sieve. The fine particle size can promote the rapid mixing of the powder into a paste, and improve the shapeability of the paste.

[0024] Refractory fiber Refractory fiber can strengthen the mechanical properties of the material after drying and prevent cracking. The best fiber length of refractory fiber is 4mm~6mm;

[0025] SiO 2 Micropowder and sodium hexametaphosphate play the role of binder;

[0026] Quicklime powder can generate heat after adding water and mixing, avoiding the phenomenon that the powder is difficult to mix in a low temperature environment.

[0027] (2) Powder production: Fully mix the powder prepared in step (1) by hand or...

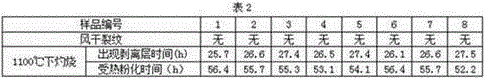

Embodiment 2

[0035] (1) Raw material preparation: 79.5 parts of magnesia powder, 8.7 parts of dry clay powder, SiO 2 1.7 parts of fine powder, 5.6 parts of sodium hexametaphosphate, 3.5 parts of quicklime powder, and 3 parts of refractory fiber.

[0036] The magnesia powder passes through the 200-mesh sieve, and the dry clay powder passes through the 380-mesh sieve. The fine particle size can promote the rapid mixing of the powder into a paste, and improve the shapeability of the paste.

[0037] Refractory fiber Refractory fiber can strengthen the mechanical properties of the material after drying and prevent cracking. The best fiber length of refractory fiber is 4mm~6mm;

[0038] SiO 2 Micropowder and sodium hexametaphosphate play the role of binder;

[0039] Quicklime powder can generate heat after adding water and mixing, avoiding the phenomenon that the powder is difficult to mix in a low temperature environment.

[0040] (2) Powder production: Fully mix the powder prepared in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com