A zno load cdin 2 the s 4 Preparation method and application of nanocube composite photocatalyst

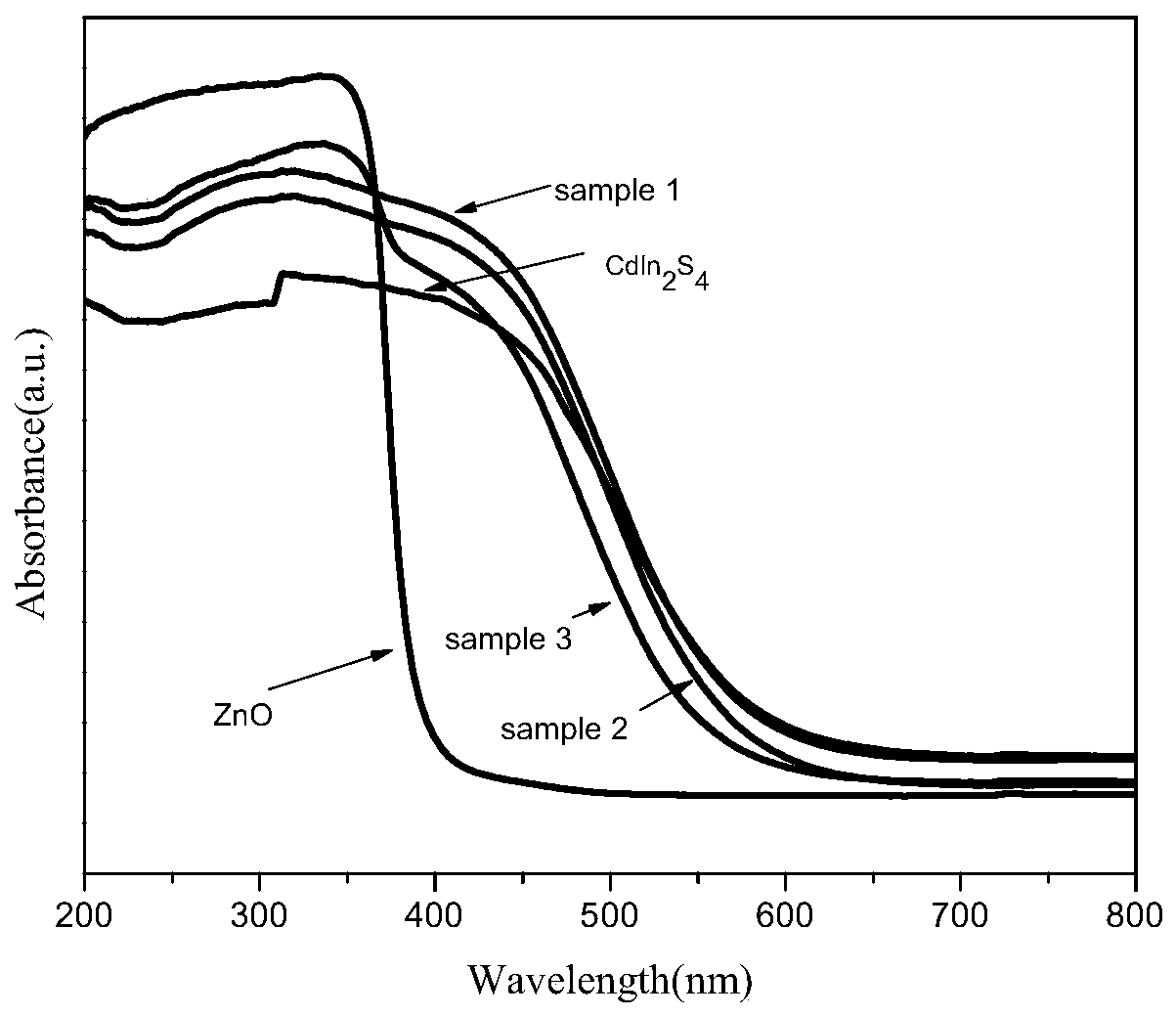

A cube and composite light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve large specific surface area, facilitate large-scale production, and wide spectral response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Measure absolute ethanol and deionized water in a beaker in sequence to obtain 30 mL of ethanol aqueous solution, wherein the volume ratio of absolute ethanol and deionized water is 1:0.5.

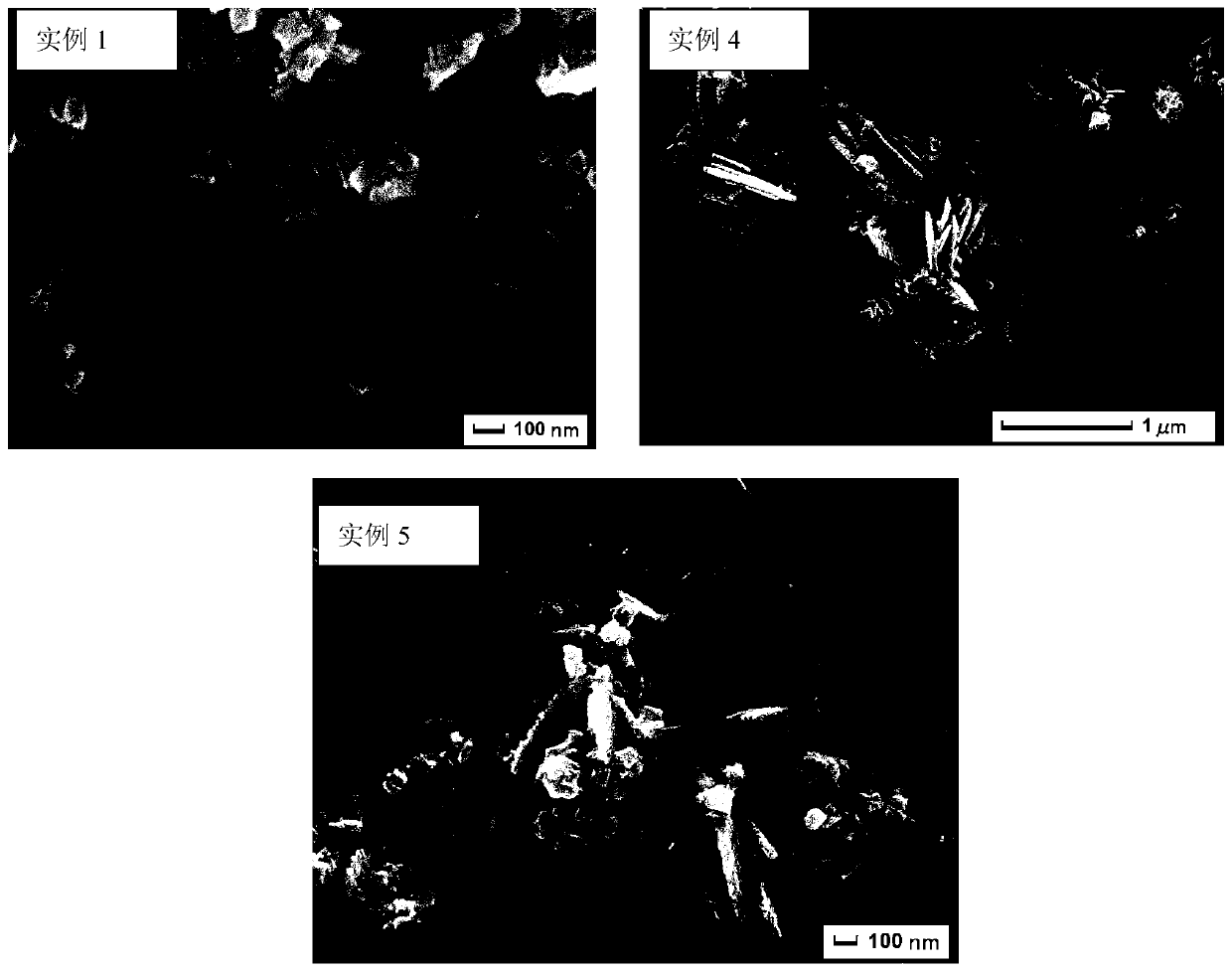

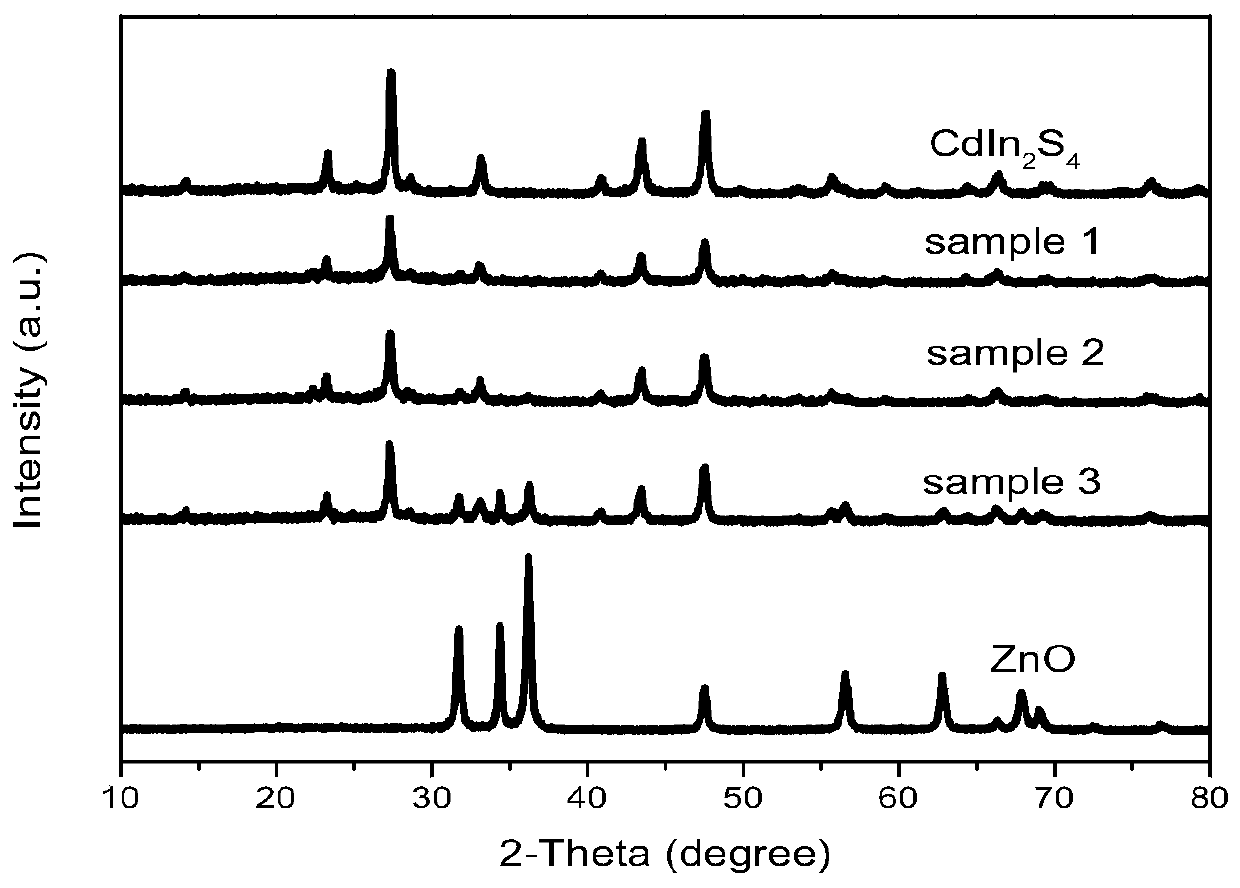

[0035](2) Weigh 0.1233g, 0.3056g and 0.2104g of cadmium nitrate, indium nitrate hydrate and thioacetamide respectively, and add them in sequence to the ethanol aqueous solution obtained in step (1). Stir for 10 minutes and sonicate for 5 minutes to form a yellowish solution. Transfer the obtained solution to a polytetrafluoroethylene-lined autoclave for 24 hours at 180 ° C. After the reactor is cooled to room temperature, the solid in the solution is After centrifugation and ultrasonic cleaning with ethanol and water for three times, dry at 80°C for 12 hours to synthesize CdIn 2 S 4 The nano cube is 0.187g, and the side length of the cube is 50-100nm.

[0036] (3) Weigh 0.06g CdIn 2 S 4 Add nanocubes to 10ml of deionized water, and sonicate for 10 minutes to obtain CdIn 2 S...

Embodiment 2

[0044] (1) Sequentially measure absolute ethanol and deionized water into a beaker to obtain 60 mL of ethanol aqueous solution, wherein the volume ratio of absolute ethanol and deionized water is 1:0.7.

[0045] (2) Weigh 1.233g, 3.056g and 2.104g of cadmium nitrate, indium nitrate hydrate and thioacetamide respectively, and add them in sequence to the aqueous ethanol solution obtained in step (1). Stir for 15 minutes and sonicate for 10 minutes to form a yellowish solution. Transfer the obtained solution to a polytetrafluoroethylene-lined autoclave for 28 hours at 180°C. After the reactor is cooled to room temperature, the solid in the solution is After centrifugation and ultrasonic cleaning with ethanol and water for three times, dry at 80°C for 12 hours to synthesize CdIn 2 S 4 The nano cube is 1.87g, and the side length of the cube is 50-100nm.

[0046] (3) Weigh 0.5g CdIn 2 S 4 Add nanocubes into 50ml deionized water, and ultrasonicate for 15min to obtain CdIn 2 S 4...

Embodiment 3

[0053] (1) Sequentially measure absolute ethanol and deionized water into a beaker to obtain 90 mL of ethanol aqueous solution, wherein the volume ratio of absolute ethanol and deionized water is 1:0.8.

[0054] (2) Weigh 2.466g, 6.112g and 4.208g of cadmium nitrate, indium nitrate hydrate and thioacetamide respectively, and add them to the aqueous ethanol solution obtained in step (1) in sequence. Stir for 20 minutes and sonicate for 15 minutes to form a yellowish solution. Transfer the obtained solution to a polytetrafluoroethylene-lined autoclave for 32 hours at 180 ° C. After the reactor is cooled to room temperature, the solid in the solution is After centrifugation and ultrasonic cleaning with ethanol and water for three times, dry at 80°C for 12 hours to synthesize CdIn 2 S 4 The nano cube is 3.74g, and the side length of the cube is 50-100nm.

[0055] (3) Weigh 1.5g CdIn 2 S 4 Add nanocubes to 100ml of deionized water, and sonicate for 20 minutes to obtain CdIn 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com