Polylactic acid / beta-calcium phosphate / I type collagen composite nerve conduit and preparation method thereof

A nerve catheter, polylactic acid technology, applied in the fields of medical science, prosthesis, tissue regeneration, etc., can solve the problems of not being able to meet the needs of nerve repair, poor catheter performance, etc. , enhance the cell affinity and hydrophilicity, the effect of high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

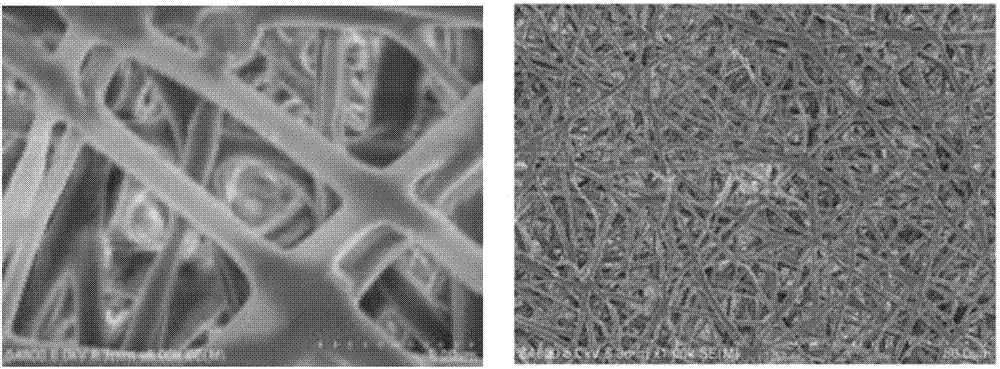

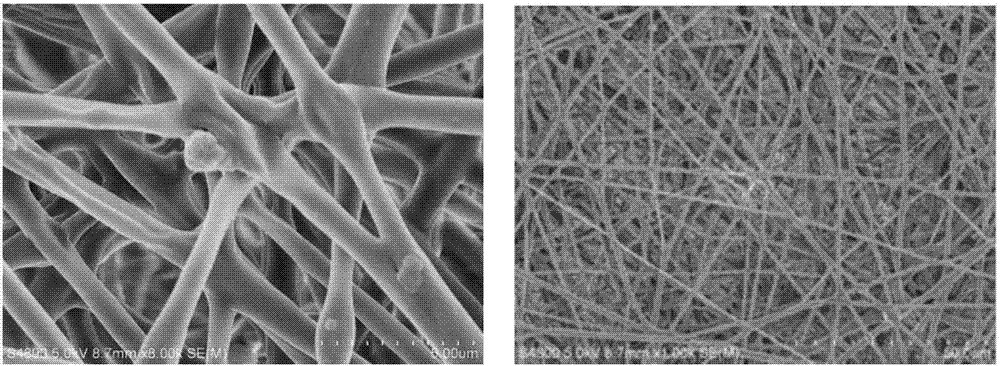

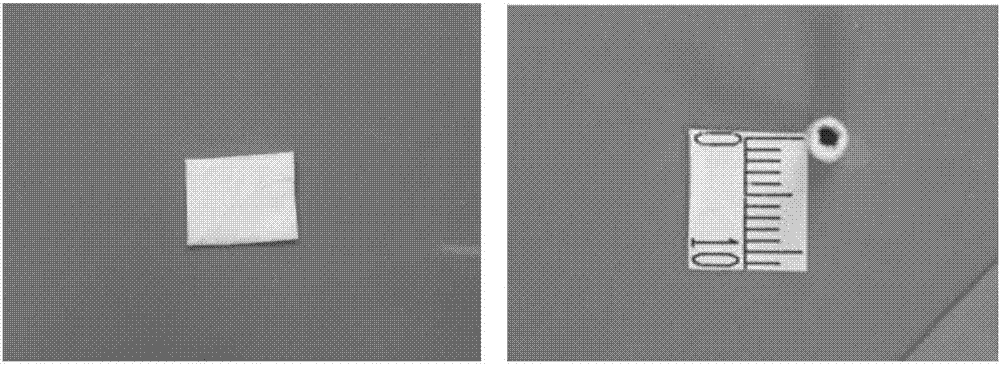

Embodiment 1

[0032] Weigh 0.3g of polylactic acid and 0.9g of type I collagen in 10mL of organic solvent (dichloromethane:ethyl acetate volume ratio is 7:4) with an electronic balance, and use an electromagnetic stirrer to stir for 6h to mix the solution evenly. To obtain a uniform and stable polylactic acid / type I collagen spinning solution, use a No. 21 needle to control spinning parameters (spinning solution flow rate 0.1mm / min, positive high voltage +10kV, negative high voltage -3kV, spinning membrane receiving device and jet The needle distance is 13cm), and the spinning solution is made into a 0.15mm thick spinning film (inner layer); similarly, 0.8g polylactic acid is weighed with an electronic balance, and 0.2g β-calcium phosphate is dissolved in 10mL organic solvent (dichloromethane: The volume ratio of ethyl acetate is 7:4), using an electromagnetic stirrer to stir for 6h, the solution is mixed to obtain a uniform and stable polylactic acid / β-calcium phosphate spinning solution, u...

Embodiment 2

[0034] Weigh 0.4g polylactic acid and 1.2g type I collagen in 10mL organic solvent (dichloromethane: ethyl acetate volume ratio is 7:4) with an electronic balance, and use an electromagnetic stirrer to stir for 6h to mix the solution evenly. To obtain a uniform and stable polylactic acid / type I collagen spinning solution, use a No. 21 needle to control spinning parameters (spinning solution flow rate 0.2mm / min, positive high voltage +10kV, negative high voltage -3kV, spinning membrane receiving device and jet The needle distance is 14cm), and the spinning solution is made into a 0.15mm thick spinning film (inner layer); similarly, 1.0g polylactic acid is weighed with an electronic balance, and 0.25g β-calcium phosphate is dissolved in 10mL organic solvent (dichloromethane: The volume ratio of ethyl acetate is 7:4), using an electromagnetic stirrer to stir for 6h, the solution is mixed to obtain a uniform and stable polylactic acid / β-calcium phosphate spinning solution, using No...

Embodiment 3

[0036]Weigh 0.5g of polylactic acid and 1.5g of type I collagen in 10mL of organic solvent (dichloromethane:ethyl acetate volume ratio is 7:4) with an electronic balance, and stir for 6h with an electromagnetic stirrer to mix the solution evenly. To obtain a uniform and stable polylactic acid / type I collagen spinning solution, use a No. 21 needle to control spinning parameters (spinning solution flow rate 0.1mm / min, positive high voltage +10kV, negative high voltage -3kV, spinning membrane receiving device and jet The needle distance is 14cm), and the spinning solution is made into a 0.15mm thick spinning film (inner layer); similarly, 1.2g polylactic acid is weighed with an electronic balance, and 0.3g β-calcium phosphate is dissolved in 10mL organic solvent (dichloromethane: The volume ratio of ethyl acetate is 7:4), using an electromagnetic stirrer to stir for 6h, the solution is mixed to obtain a uniform and stable polylactic acid / β-calcium phosphate spinning solution, usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com