A kind of microfluidic control system and its preparation process

A microfluidic system and preparation process technology, applied in the field of microfluidics, can solve problems such as the inability to meet product customization, and achieve the effects of high integration, convenient use and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

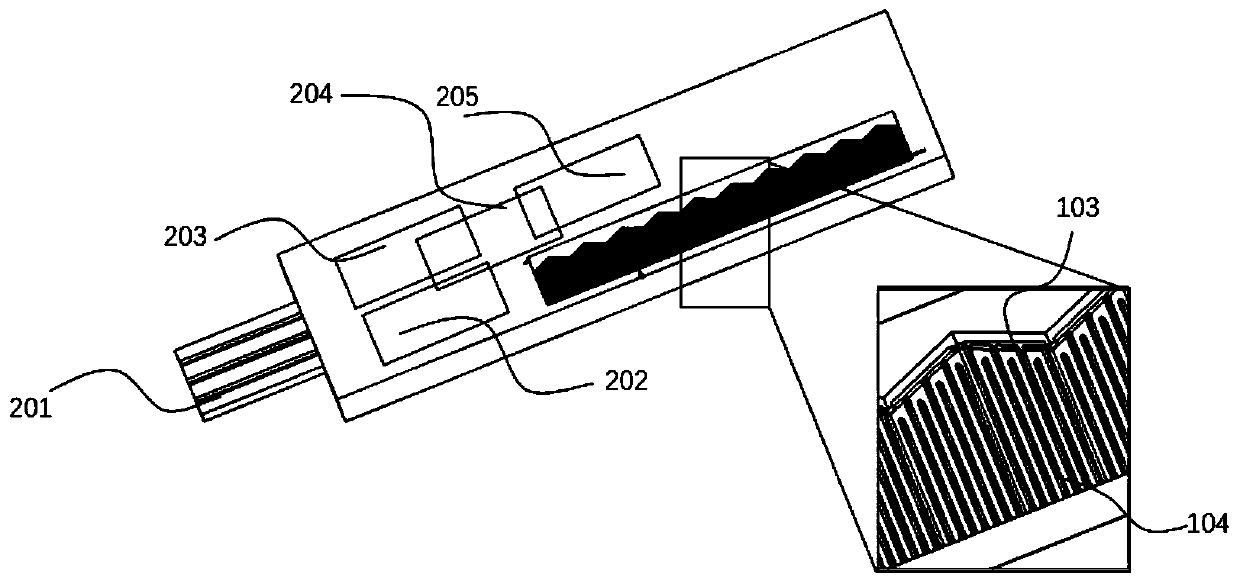

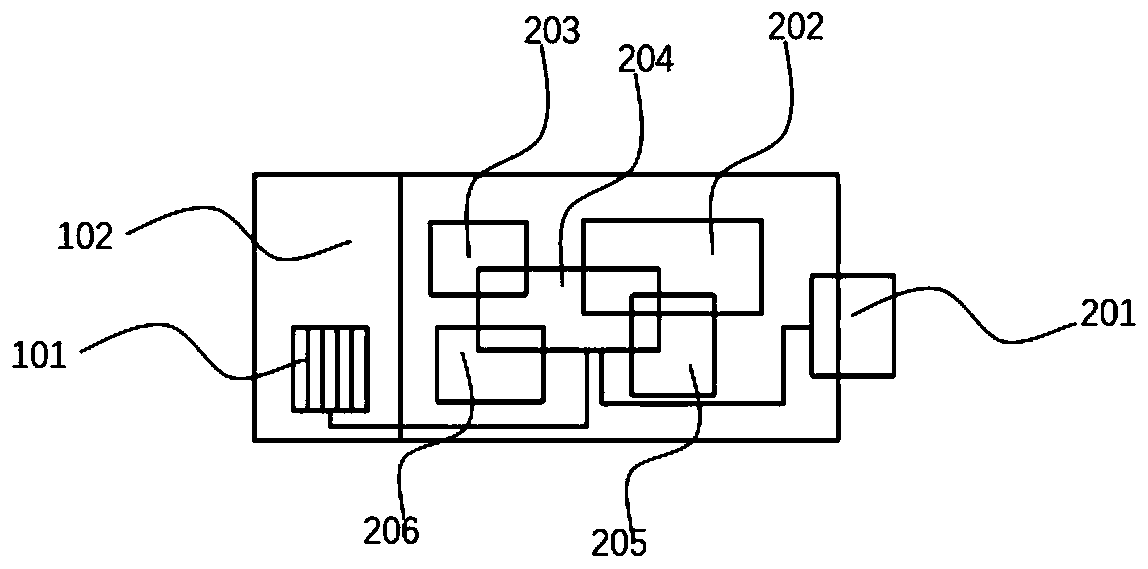

[0046] Making the microfluidic chip: mix Dow Corning 184 colloid and curing agent at a ratio of 10:1 to make PDMS, then put it into the mold for preparing the microfluidic chip substrate 206, and die-cast to obtain the microfluidic chip substrate 206. Then a microfluidic system ( 201 , 202 , 203 , 204 , 205 ) is fabricated on the microfluidic chip substrate 206 by MEMS technology to obtain a microfluidic chip.

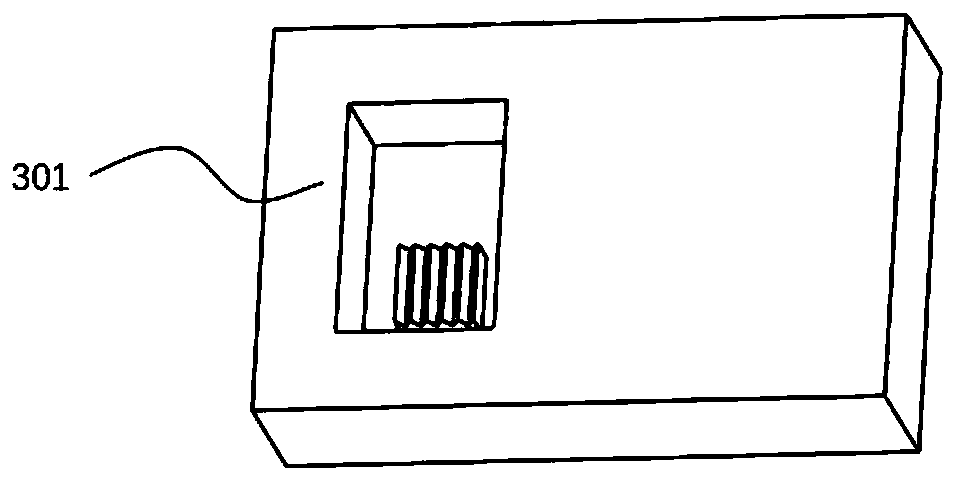

[0047] To make the flexible battery chip substrate 102: mix the colloid of SE1700 and the curing agent at a ratio of 10:1, and place the mold 301 in the tooth-shaped area (such as image 3 shown in ), to obtain a flexible battery chip substrate 102 (such as Figure 4 shown). The resulting flexible battery chip base 102 has a serrated region 101 composed of continuous triangles 105 . The peak height of the triangle 105 is preferably 50-3000 μm, and the base length of the triangle 105 is preferably 100-5000 μm. The plane where the base of the triangle 105 is located i...

Embodiment 2

[0058]Embodiment 2 is basically the same as Embodiment 1, except that the configuration of the positive / negative electrode slurry (108, 109) is different, and its specific process is as follows: (1) active materials such as LFP, LTO and other materials are mixed with ethanol solution according to 0.1g / ml is mixed and transferred to a ball mill for ball milling for 8h, and the rotating speed is set at 500rpm; (2) the mixture of active materials LFP, LTO and ethanol, multi-walled carbon nanotubes, binder HPC (hydroxypropyl cellulose, molecular weight 1,000,000 ), the dispersant pvp was put into the petri dish respectively, and the upper part of the petri dish was sealed with a dust-free paper, put into a vacuum oven at 150°C, baked for 12 hours, took it out and put it into a desiccator for storage; (3) filled with argon In the glove box, take 4g binder HPC and dissolve it in 20ml 1,4-dioxane solution, add 0.5g each time, stir evenly with a glass rod, wrap the lid of the reagent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com