Full-automatic dispensing and LED lamp mounting equipment for flexible circuit board

A technology of flexible circuit boards and LED lights, which is applied in the fields of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of assembly line labor consumption, unguaranteed lamp quality, and high defective rate, so as to improve production efficiency and yield , Reduce the effect of manual alignment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

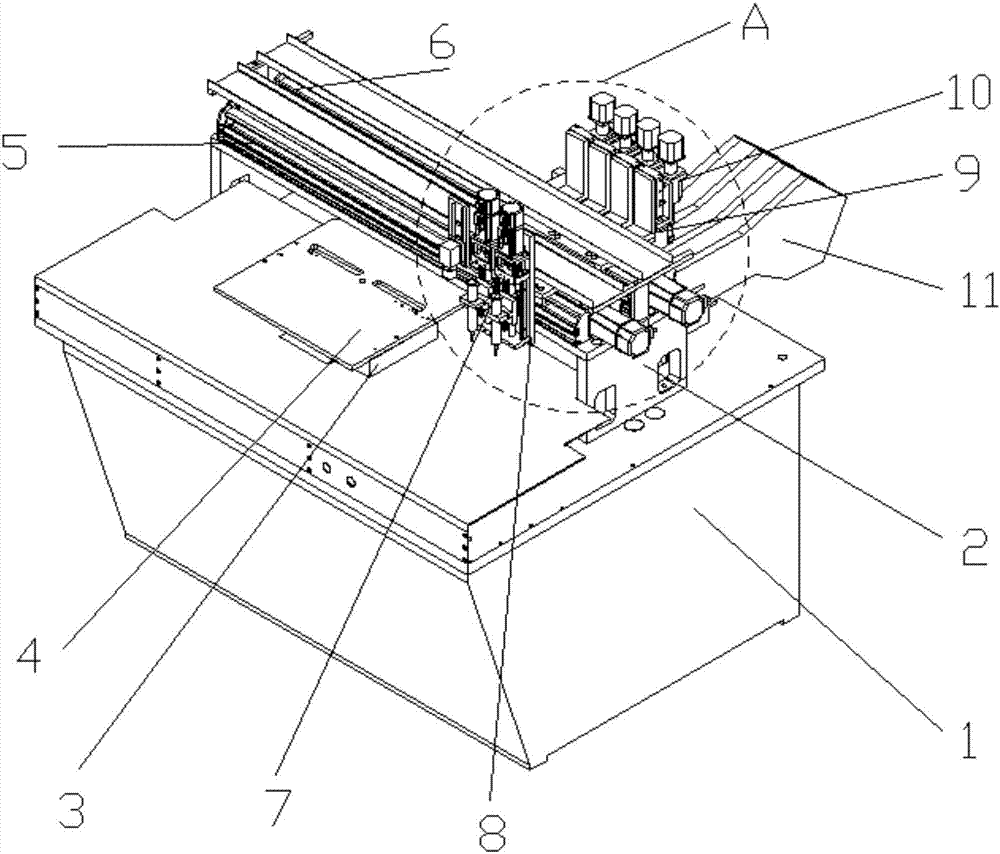

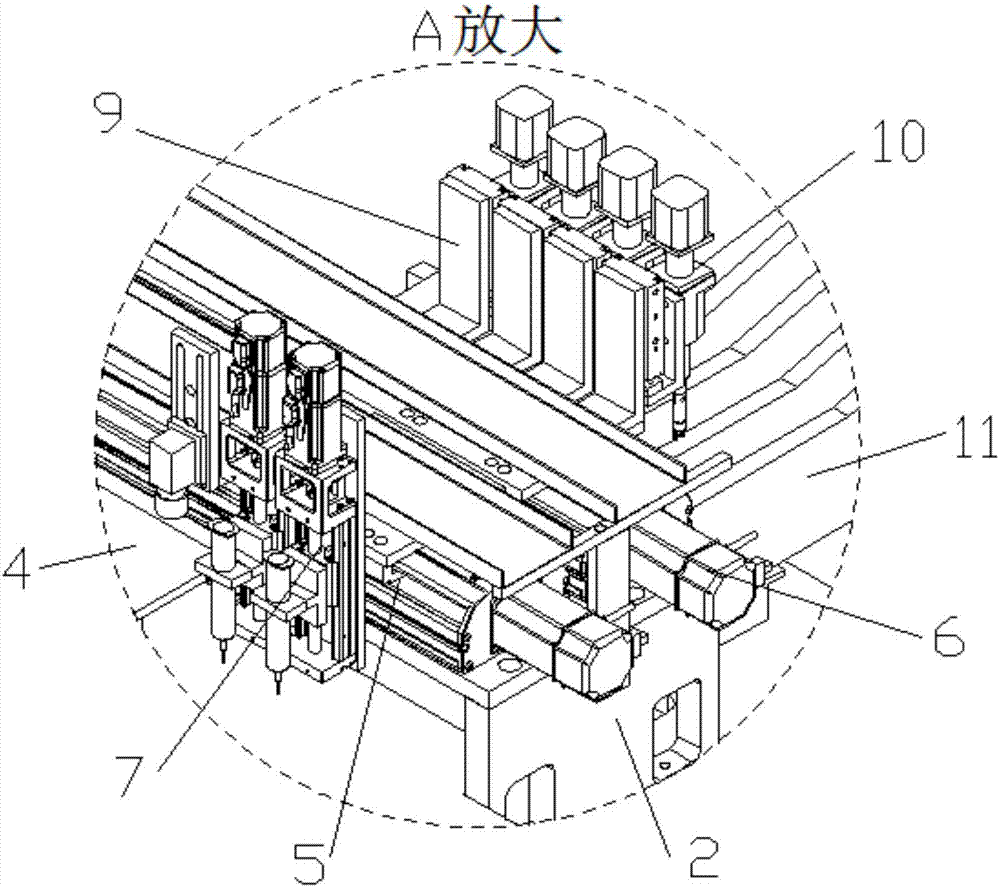

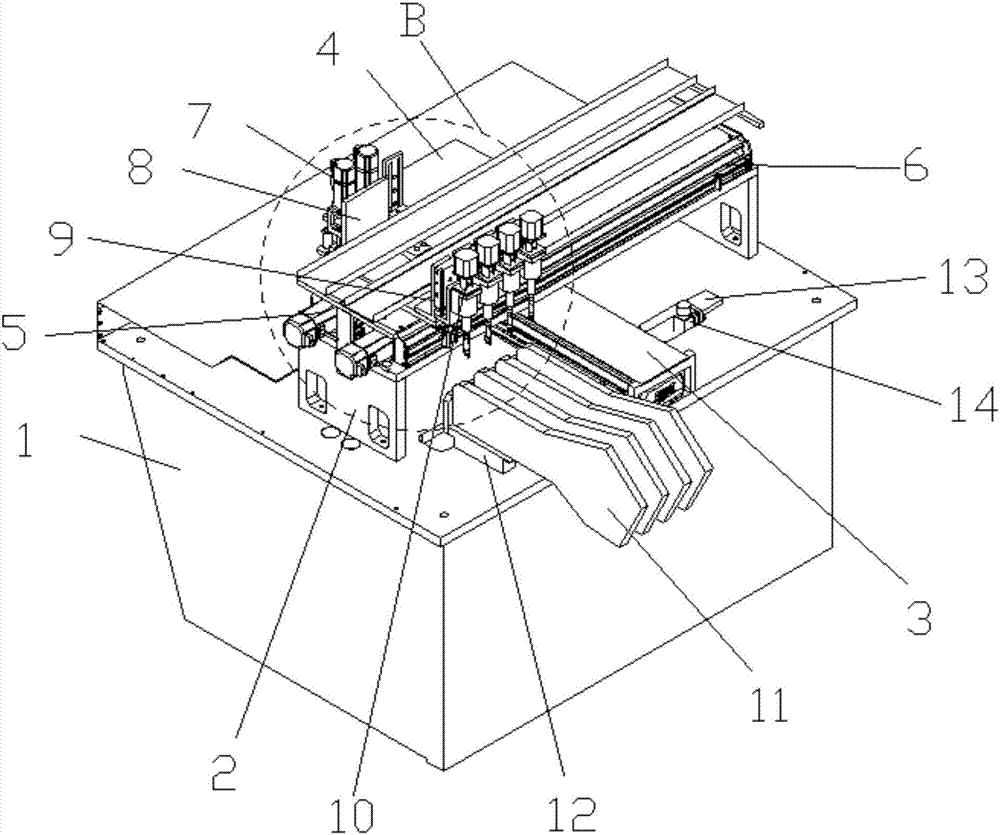

[0014] Such as Figure 1-4 As shown, a kind of flexible printed circuit board automatic dispensing and pasting LED lamp equipment described in this specific embodiment includes a base 1, a sliding platform seat 2, a platform transfer sliding platform 3, a platform 4, a dispenser sliding platform 5, Sticker slide table 6, glue dispenser 7, glue dispenser mounting plate 8, light sticking device mounting plate 9, light sticking device 10, light feeder 11, feeder seat 12, camera connection seat 13, LED light photo The camera 14; the slide base 2 is installed horizontally on the upper part of the base 1; the platform transfer slide 3 is installed longitudinally on the base 1; the platform 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com