Display panel, making method and display device

A technology of a display panel and a manufacturing method, applied in the field of display panels, manufacturing methods and display devices, can solve the problems of adverse effects of resin material performance, influence on performance of display panels, increase of manufacturing time, etc., so as to shorten the manufacturing time, avoid adverse effects, Avoiding the effect of threshold voltage drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

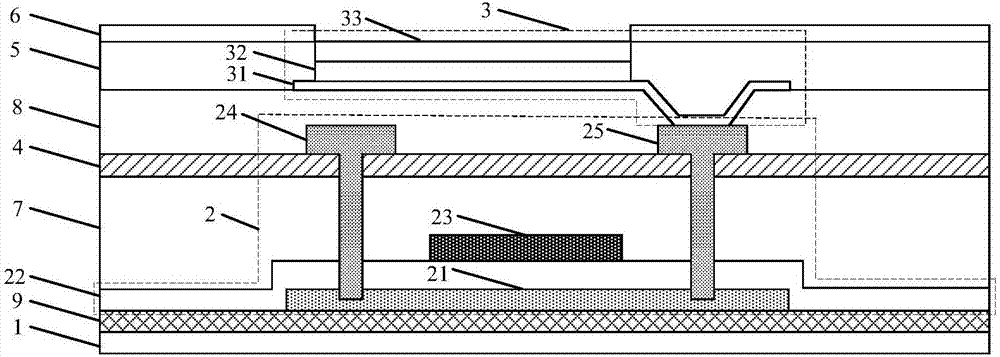

[0032] Such as figure 1 As shown, this embodiment provides a display panel, including a base substrate 1 , a thin film transistor 2 formed on the base substrate 1 , and a light emitting structure 3 formed on the side of the thin film transistor 2 facing away from the base substrate 1 . Wherein, the thin film transistor 2 includes a polysilicon layer 21 located between the light emitting structure 3 and the base substrate 1 . A light-shielding layer 4 for blocking ultraviolet light is also formed between the polysilicon layer 21 and the light-emitting structure 3 . The orthographic projection of the light-shielding layer 4 on the base substrate 1 covers the orthographic projection of the polysilicon layer 21 on the base substrate 1 .

[0033] It can be understood that the light emitting structure 3 may specifically include an anode 31 , a light emitting layer 32 and a cathode 33 , wherein the anode 31 is electrically connected to the thin film transistor 2 . After the anode 31...

Embodiment 2

[0046] This embodiment provides a method for manufacturing a display panel, and the method for manufacturing a display panel is applied to the display panel described in Embodiment 1.

[0047] Such as Figure 5 As shown, the manufacturing method of the display panel specifically includes:

[0048] Step S1: providing a base substrate.

[0049] Step S2: forming a thin film transistor and a light-shielding layer for blocking ultraviolet light on the base substrate, so that the thin film transistor includes a polysilicon layer; the light-shielding layer is located on the side of the polysilicon layer facing away from the base substrate, and the light-shielding layer is projected on the front of the base substrate Orthographic projection of the covering polysilicon layer on the base substrate.

[0050] Step S3: forming a light-emitting structure on the side of the light-shielding layer facing away from the polysilicon layer.

[0051] Using the manufacturing method of the display...

Embodiment 3

[0065] This embodiment provides a display device, and the display device includes the display panel as described in the first embodiment.

[0066] Since the display device provided in this embodiment includes the display panel as described in Embodiment 1, the display device can avoid the adverse effect of ultraviolet light on the polysilicon layer, thereby avoiding the problem of threshold voltage shift of the thin film transistor. Moreover, since no additional annealing process is required, the manufacturing time of the display device is shortened and the production capacity is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com