Polaroid with water-proof nano-coating and liquid crystal display

A liquid crystal display and nano-coating technology, applied in optics, instruments, polarizing components, etc., can solve problems such as durability failure, poor water resistance of polarizers, and the influence of polarized PVA layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

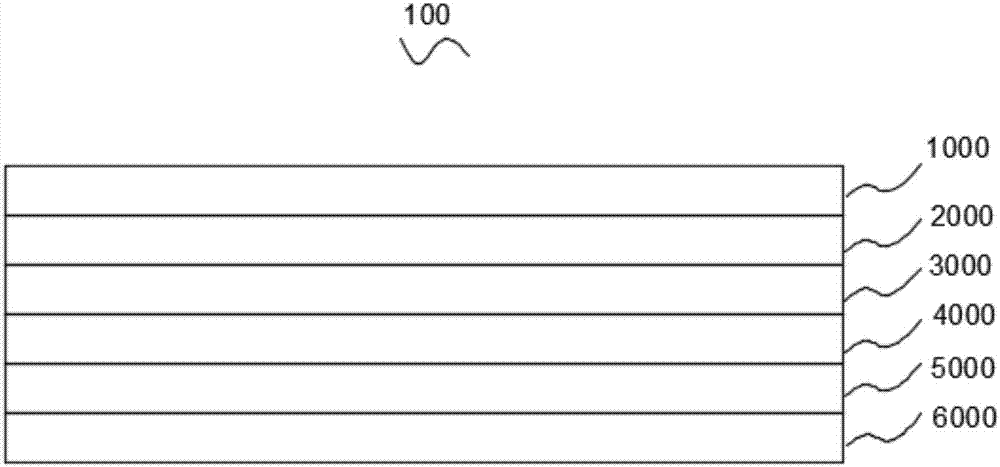

[0043] see figure 1 , the present embodiment provides a polarizer 100 (hereinafter referred to as "polarizer 100") having a water-resistant nano-coating 1000, including sequentially pasted:

[0044] Water-resistant nano-coating 1000, used to resist water vapor and provide structural strength;

[0045] A first TAC film 2000 for providing protection;

[0046] PVA film 3000, used as a polarizing layer;

[0047] A second TAC film 4000 for protection;

[0048] PSA adhesive layer 5000 for providing bonding properties;

[0049] Release film 6000, used to provide isolation, filling and protection.

[0050] Wherein, the waterproof performance of the water-resistant nano-coating 1000 comes from the small gaps formed by the nano-scale particles, which make it difficult for water molecules to pass through.

[0051] Preferably, in this embodiment, the nano-particles in the water-resistant nano-coating 1000 have the same direction. Due to the improved arrangement of nanoparticles, the...

Embodiment 2

[0074] This embodiment provides a liquid crystal display, including a surface glass substrate, a bottom glass substrate, and a liquid crystal layer. A polarizer 100 is provided on the outside of the surface glass substrate or the bottom glass substrate. The polarizer 100 includes:

[0075] Water-resistant nano-coating 1000, used to resist water vapor and provide structural strength;

[0076] A first TAC film 2000 for providing protection;

[0077] PVA film 3000, used as a polarizing layer;

[0078] A second TAC film 4000 for protection;

[0079] PSA adhesive layer 5000 for providing bonding properties;

[0080] Release film 6000, used to provide isolation, filling and protection.

[0081] Wherein, the waterproof performance of the water-resistant nano-coating 1000 comes from the small gaps formed by the nano-scale particles, which make it difficult for water molecules to pass through.

[0082] Preferably, in this embodiment, the nano-particles in the water-resistant nano-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com