Automatic combustion stabilization system used for corner tangential boiler

A four-corner tangential and boiler technology, which is applied to the combustion of block fuel and liquid fuel, the combustion of block fuel and gaseous fuel, and the combustion of block fuel and powder fuel, which can solve the problem of large oil consumption , huge fuel consumption and other issues, to achieve the effect of safe installation position, good safety, and enhanced combustion-supporting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

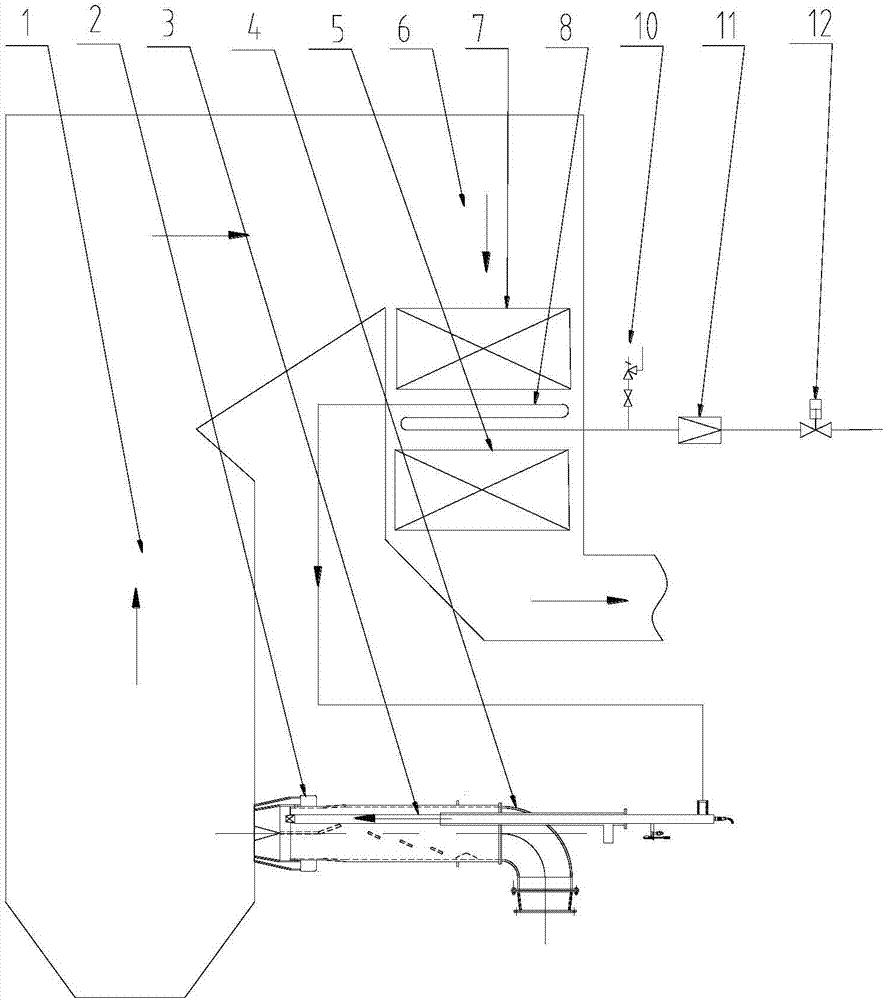

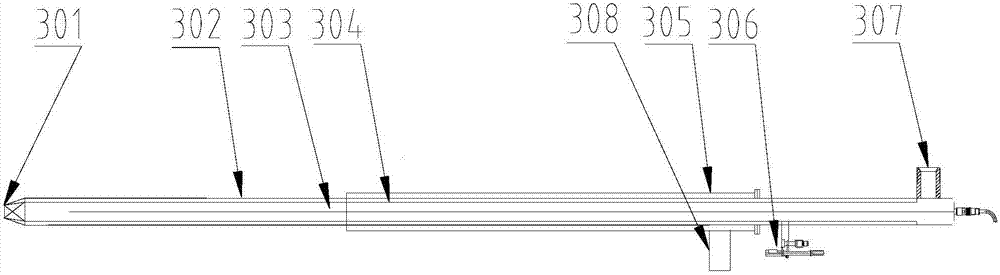

[0024] Such as figure 1 with 2As shown, an automatic stable combustion system for a four-corner tangential boiler in this embodiment includes a louver pulverized coal burner 2, a high-temperature oxygen generator assembly 3, a pulverized coal pipe elbow 4, an economizer 5, and a low-temperature Reheater 7 and oxygen heater 8, described louver pulverized coal burner 2 is installed on the four corners of four corners tangential circle boiler hearth 1 bottom, pulverized coal pipe elbow 4 is connected with the inlet of louver pulverized coal burner 6, The high temperature oxygen generator assembly 3 horizontally passes through the pipe wall of the pulverized coal pipe elbow 4 and extends into the dense phase measurement of the louver pulverized coal burner 6, and the nozzle of the high temperature oxygen generator assembly 3 is located in the louver pulverized coal burner 6 At the outlet of the dense phase side, the low-temperature reheater 7, oxygen heater 8 and economizer 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com