Glass fiber-reinforced polymer concrete segment of shield tunnel lining and manufacturing method of glass fiber reinforced concrete segment

A glass fiber reinforced and shield tunnel technology, which is applied in tunnel lining, tunnel lining, shaft lining, etc., can solve the problems of high cost of metal segments, poor oxidation and corrosion resistance, slow construction progress, etc., and achieves improved service life and tensile strength The effect of high strength and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

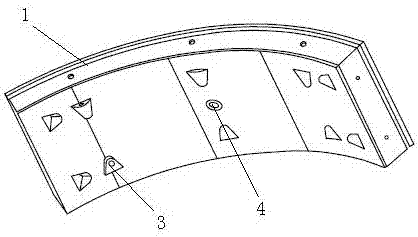

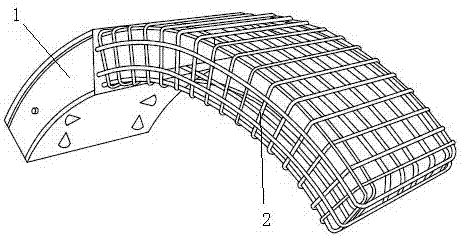

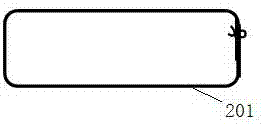

[0033] refer to Figure 1-11 , the specific embodiment adopts the following technical solutions: a shield tunnel lining glass fiber reinforced concrete segment, including concrete 1 and a glass fiber cage 2 composed of glass fiber reinforcement in various shapes, and concrete is poured in the glass fiber cage 2 1. The surface of the concrete 1 is provided with connecting holes 3 and hoisting holes 4, and the glass fiber cage 2 is composed of rectangular glass fiber bars 201, triangular glass fiber bars 202, square glass fiber bars 203, curved rectangular glass fiber bars 204, There are curved glass fiber bars 205, rectangular glass fiber bars 206 with openings, short glass fiber bars 207 with arcs and glass fiber bars 208 for binding. The rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com