Method for improving selectivity of trichlorosilane

A technology of trichlorosilane and selectivity, which is applied in the field of catalytic chemistry, can solve the problems of wasting resources, low selectivity of trichlorosilane, and waste silicon powder, etc., so as to save costs, realize solid waste recycling, and improve selectivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

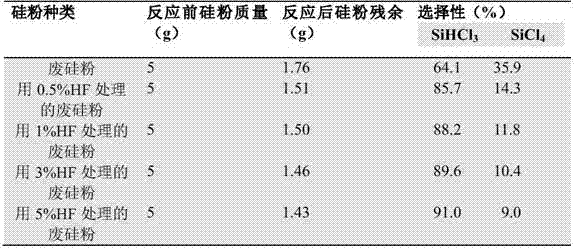

Embodiment 1

[0017] Take 30g of waste silicon powder from the factory, put the waste silicon powder into a plastic beaker, pour it into 100mL of hydrofluoric acid with a content of 0.5%, and stir it with a glass rod for 1h. Then perform suction filtration and washing, and finally put the filter cake into a vacuum oven for drying. Weigh 5 g of waste silicon powder treated with hydrofluoric acid, put it into a fixed-bed reactor, then put the fixed-bed reactor into a tube furnace, and heat it with nitrogen gas flow rate of 100 mL / min. When the tube furnace is heated to 280°C, switch to hydrogen chloride, the flow rate of hydrogen chloride is 80mL / min, the reaction product is cooled at -20°C, and the products after the reaction are the main product trichlorosilane and the by-product silicon tetrachloride. Calculate the selectivity of trichlorosilane. The experimental results are shown in Table 1.

Embodiment 2

[0019] Take 30g of waste silicon powder from the factory, put the waste silicon powder into a plastic beaker, pour 100mL of hydrofluoric acid with a content of 1% and stir with a glass rod for 1 hour, then perform suction filtration and washing, and finally put the filter cake into Dry in a vacuum oven. Weigh 5 g of waste silicon powder treated with hydrofluoric acid, put it into a fixed-bed reactor, then put the fixed-bed reactor into a tube furnace, and heat it with nitrogen gas flow rate of 100 mL / min. When the tube furnace is heated to 280°C, switch to hydrogen chloride, the flow rate of hydrogen chloride is 80mL / min, the reaction product is cooled at -20°C, and the products after the reaction are the main product trichlorosilane and the by-product silicon tetrachloride. Calculate the selectivity of trichlorosilane. The experimental results are shown in Table 1.

Embodiment 3

[0021] Take the waste silicon powder from the factory, put the waste silicon powder into a plastic beaker, pour in 3% hydrofluoric acid and stir it with a glass rod for 1 hour, then carry out suction filtration and washing, and finally put the filter cake into a vacuum oven for drying drying. Weigh 5 g of waste silicon powder treated with hydrofluoric acid, put it into a fixed-bed reactor, then put the fixed-bed reactor into a tube furnace, and heat it with nitrogen gas flow rate of 100 mL / min. When the tube furnace is heated to 280°C, pass hydrogen chloride, the flow rate of hydrogen chloride is 80mL / min, the reaction product is cooled at -20°C, and the products after the reaction are the main product trichlorosilane and the by-product silicon tetrachloride. Calculate the selectivity of trichlorosilane. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com